A frying pan is an essential attribute in every kitchen. This is a container that is directly involved in the cooking process. If previously almost everyone used cast-iron pans, today the assortment is more than large. The modern market for cookware offers a variety of options for the consumer, but non-stick products are most popular. We will talk about them in this article.

What it is?

A non-stick coating is called a protective layer, the main purpose of which is to protect the surface of the used container from burning and scaling. The frying pan is used for frying products, and the material from which it is made is prone to oxidize, thereby forming scale and fumes at the bottom of the container. Non-stick coating avoids this and does not spoil the products that are cooked.

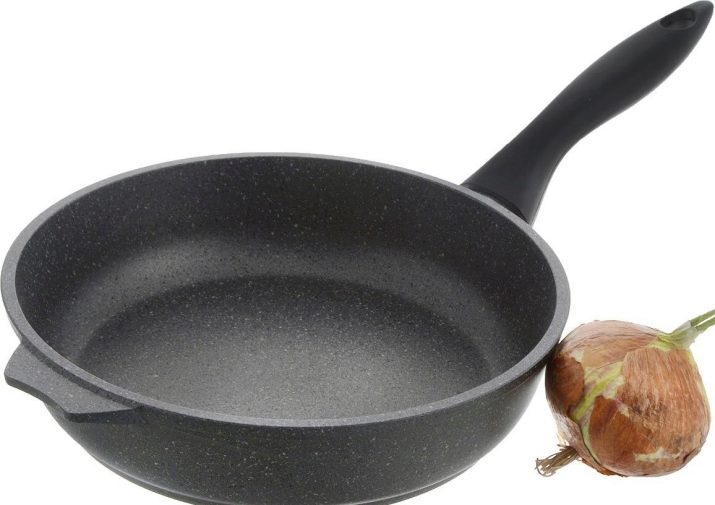

The non-stick pan looks the same as the familiar frying pan. That is, visually it is no different, only its bottom is covered with a protective layer. There are models that have a similar protective layer on the outside. Due to the properties of the coating, pans with such a protective layer are popular with housewives.

Kinds

Non-stick coating of the pan can be made of different materials. Consider the best types of coatings.

- Teflon. This is the most popular type of non-stick coating. Teflon was the first non-stick material that began to be applied to pans.Polytetrafluoroethylene, a chemical compound obtained in 1938, is used for its production.

- Ceramic. This is a nanocomposite polymer substance, consisting of the smallest particles of sand. In practice, two methods of applying this protective layer are used: spraying and rolling. In the first case, the outer and inner sides of the already made pan are covered. This method makes it possible to obtain a reliable, durable and practical tank with a perfectly flat bottom. Roll-over involves the application of a protective layer on a metal sheet, from which a frying pan will be further made. Tanks made by this method are called cast. It is also worth noting that there are many different options for a frying pan with a ceramic protective layer. For example, this is a white coating, which is obtained by staining ceramics.

- Marble. The marble coating of the pan is the same Teflon, only with the addition of a protective layer of marble chips.

- From non-composite materials. This is a pan with granite, titanium and diamond coating. Frying pans with these types of coverage are the most expensive. The cost of capacity is due to the properties of the substances used.

Advantages and disadvantages

Earlier in the article, we talked about what types of non-stick protective layer exist. Now it's time to discuss in more detail the advantages and disadvantages of each of the above species.

Teflon

This type of non-stick coating is considered the ancestor of all protective layers.

The advantages are quite significant:

- possesses high non-stick properties;

- unpretentious in leaving;

- affordable price.

But there are a lot of shortcomings:

- the maximum heating temperature is 200 ° C, this is due to the fact that Teflon, when exposed to high temperature, begins to emit harmful substances;

- when frying foods, it is advisable to use vegetable or butter;

- the container can not be used for long cooking;

- Teflon coating is unstable: any mechanical impact on it will lead to deformation and damage;

- if the Teflon protective layer in the pan is damaged, then the use of a container is further categorically not recommended, it is harmful to health;

- it is impossible to cool a hot tank with cold water.

Ceramic

Such a pan is in great demand today, and there are several reasons for this:

- resistance to high temperatures - the pan can be heated up to 450 ºС;

- easy to care for;

- when cooking, you need a minimum of oil.

Cons of ceramics:

- poorly tolerates temperature differences;

- when stirring, metal blades and appliances should not be used;

- Use special detergents and an exceptionally soft sponge.

Marble

This kind of protective coating It has a number of advantages:

- resistance to mechanical stress;

- fast and uniform heating;

- ability to maintain temperature for a long time;

- does not deform when exposed to high temperature or its differences;

- the cooking process occurs without adding oil;

- long service life, which with proper care can be about 2 years.

No matter how many advantages this type of coating has, there were some disadvantages:

- a marble-coated pan is quite expensive;

- the coating deteriorates when using abrasive and chemical substances during washing;

- there are restrictions on the use of the dishwasher;

- strong mechanical stress may damage the coating.

From non-composite materials

The benefits of a coated pan of non-composite substances include:

- reliability and quality;

- long term of operation;

- fast and uniform heating;

- surface resistant to mechanical stress: it can be scratched with a knife, forks, it will not harm anything;

- preservation of temperature.

Among the shortcomings can be noted the high cost and the inability to use the pan on an induction cooker.

Sizes and shapes

Sizes and shapes, as a rule, depend on the purpose of the container and on the products that will be fried on it.

The shape of the pan can be:

- round;

- square;

- rectangular;

- oval.

Consider some of the most famous types of pans equipped with a non-stick layer.

- Classical Such a pan can be any. It is used for frying, stewing and sautéing. The diameter of the classic pan is 20-28 centimeters.

- Stewpan. So called capacity with thick sides. Its bottom is always corrugated. The stewpan comes on sale with a thermometer and a thick lid. Its biggest advantage is the uniform and quick heating of the products, this makes it possible to cook anything in a container, starting from scrambled eggs and ending with cooking soup. The diameter of the stewpan can be 24, 26 and 28 cm.

- Pancake. It is characterized by low sides, a flat bottom and a fixed handle. Pancakes and pancakes are baked on the container. The maximum size is 25 cm.

- Brazier. For the manufacture of roasting pan using high-strength steel. The bottom is made of a special alloy. This container can be used for cooking in the oven. Size is from 20 to 28 cm.

- Grill. A rather heavy frying pan with a ribbed bottom. On sale comes complete with a lid. Specialists and culinary professionals argue that products cooked in a grill pan do not lose their taste and properties during the frying process, preserve all the vitamins. Sizes are different: 25, 30, 28x28 cm.

- Wok. This is a very large and weighty pan, which is characterized by high and durable walls, a wide bottom. It is used for the preparation of sauces, marinades, semi-finished products. The diameter of the wok pan is from 28 to 32 cm.

Model Overview

On the modern market there are many different manufacturers and models of non-stick pans. Among all existing brands, I would like to separately highlight and talk about the most popular and well-established ones.

- Tefal (France). This is probably the most famous company producing pans. Absolutely every model of this brand is available with non-stick coating. In production, only high-quality material and raw materials are used. Tefal's diverse product range. You can find a cast, aluminum, stainless pan. As for the cost, there are budget options, and quite expensive.

- Rondell. The company was founded in Germany, and today has many factories around the world. The cost of the pan of this model is very high. This is due to the shelf life, which is established by the manufacturer, and the technical characteristics of the goods.

- Kukmara. This manufacturer of pans is famous for its wide range of products: these are cast, ceramic, and aluminum frying containers with a protective layer.

- TVS. This brand is also very popular, it is presented in various versions. On sale there are models with a removable handle, which is very convenient, for example, when using an oven.

- Swiss Diamond (Switzerland). This company is known for adding diamond chips to its products during the manufacturing process. The cost of production is high, due to this quality and reliability.

- Ballirini (Italy). The products are reliable, safe and have long-term rock exploitation.

- "Neva metal utensils." Such products are produced at the St. Petersburg plant. The result of the company’s work are cast pans with a protective layer. These models are quite popular, this is due to the quality and affordable price.

- "Biol." This is a Ukrainian manufacturer that makes pans exclusively from environmentally friendly materials.

It is also worth noting that on the market you can buy not one product, but a whole set.

Selection rules

It’s not so easy to choose a pan. In order for the cooking process to meet the requirements and expectations, and the products can be well fried and preserve their properties, the choice of the pan must be approached very responsibly.

There are certain criteria that should be followed.

- When choosing a pan with a Teflon coating, it is better to give preference to a model with a thickened bottom. Ensure that the Teflon protective layer is uniform and free of deformation.

- When choosing a ceramic coated frying pan, it is recommended to bypass the cheap models. The coating must be at least 4 mm thick.

- When buying a pan with a marble surface, consider the manufacturing method, wall thickness and uniformity of the protective layer.

- Of great importance is the manufacturer. Before choosing it is better to see reviews of recommended models, read reviews of real people about the manufacturer and its products. This will help to avoid many problems and disappointments.

Operation tips

A non-stick pan is expensive. You need to properly care for her, the only way to extend her life. Consider a few recommendations shared by professionals.

- It is strongly not recommended to use a metal spatula or spoon during cooking. Even if the manufacturer indicates that the surface is resistant to mechanical stress, it is still better to save it and use a wooden object for stirring.

- The pan should be washed only with a soft washcloth and a special detergent.

- During use, you need to monitor the temperature regime and remember that there are models that can not withstand high temperatures, and, for example, it is impossible to fry meat on them.

- Avoid sudden changes in temperature.

- After washing, allow the dishes to dry naturally.

Be sure to carefully read the instructions in which the manufacturer must indicate all the operating rules. There are models of pans that are not designed for the induction cooker or those that cannot be installed in the oven. Using utensils with damaged non-stick coatings is strictly prohibited.

Below you can watch a video review of popular non-stick pan models.