Even the most high-quality, reliable sewing machine crashes sooner or later. In the best case, it is necessary to carry out maintenance and take preventive measures. But sometimes repairs are needed - replacing worn parts. Replace them with your own strength if you show care and accuracy when repairing the product. Let's take a closer look at the stages of repairing a sewing machine with our own hands.

Common problems and their causes

Among the common problems are:

- the machine is bad, slowly sews or does not work at all;

- the device during operation does not catch the loop of the upper thread or does not pick up the lower thread;

- the needle or shuttle is stuck and does not move;

- the needle often breaks;

- poor fixation of the cap with the bobbin in the shuttle compartment;

- the flywheel stopped spinning.

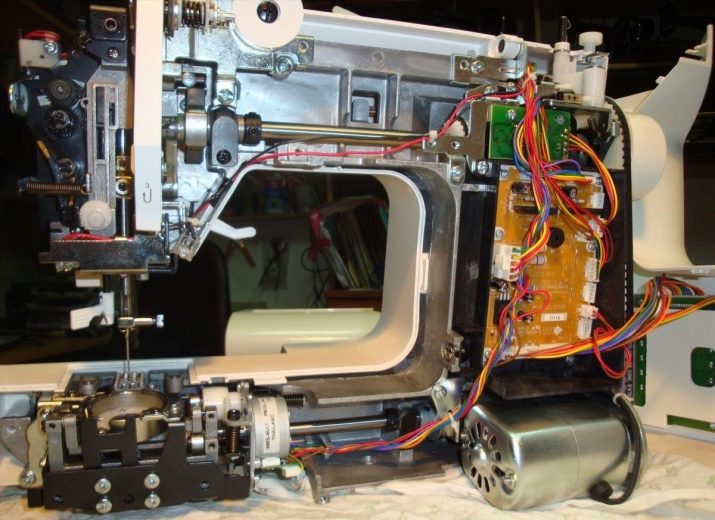

This list of faults mainly covers the state of the electromechanical model of the machine. In electronic systems, the number of various malfunctions can be supplemented by failures in electronic control boards.

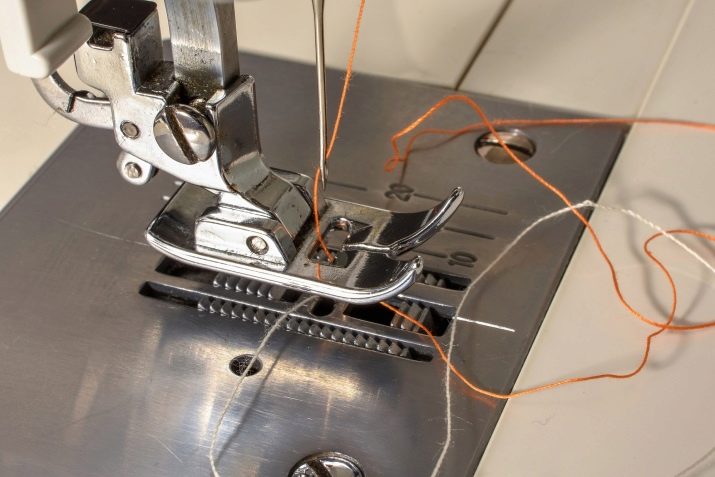

Doesn't grab the bobbin thread

The reason the shuttle does not draw the thread into the stitches is one of the following.

- Dulling the shuttle tip.

- Detuning of the shuttle mechanism, in particular, violation of its spatial orientation.

- The lower thread turned out to be thicker than the upper one, loses it in elasticity, both threads are not smooth enough and too twisted.

- The needle for this fabric is too thick or vice versa.

- The bottom thread broke. The upper thread does not capture the lower. Her entry into the seam stopped immediately after a cliff.

- The ejector is incorrectly adjusted or broken.

- The shuttle and the needle do not work at the same time. One is clearly behind the other.

- The bobbin has found burrs.

- The screw next to the shuttle is skewed or broken.

The inability to capture the lower thread leads to the fact that the seam will turn out one-sided. At the slightest load on matter stitched in this way, it will immediately blossom.

Further building the same seam with a faulty machine does not make sense.

The needle does not move

Without needle movement, you cannot start the sewing process. The reasons why the needle stops walking up and down are as follows.

- Improper care of the sewing machine. Parts, or rather, their rubbing surfaces, due to drying out and untimely replenishment of the lubricant layer, begin to wear out faster.

- Poor storage conditions. The sewing machine is not intended for keeping it in conditions of heat and cold, high humidity.

Rusty parts move worse - as a result, at the next start, the machine will jam. Parts can still be cleaned from a light rust coating, but when rusted through, they are simply replaced.

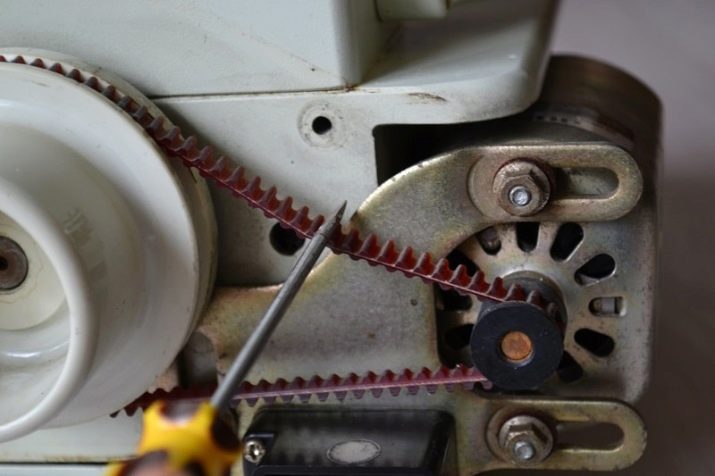

- The needle guide and the shuttle do not work harmoniously.

- The drive belt is loose or loose. This belt transmits torque from the motor shaft to the drive shaft of the common mechanism, from which both the needle bar and the shuttle operate. If movement is transmitted through gears, not belts, or through chains and sprockets, then check their integrity. Broken and worn parts must be replaced.

After checking (and replacing, when required) the specified parts, the machine will again work properly with the needle.

Flywheel does not spin

The reasons why the flywheel spins tightly or completely stops spinning are as follows.

- The machine is not lubricated with machine or industrial oil, but, say, with vegetable oil. This oil dries quickly, and plaque on the parts still remains. It acquires additional stickiness and significantly slows down the work of spinning parts.

- Old grease can also thicken when the machine has not been lubricated for many months, and it, in turn, has been working hard all this time. Then the remains of the thread, the fibers of the fabric and dust stick to the dirty parts.

- The fact is that the sewing machine is prone to vibration during operation. For example, a screw may loosen, holding the connecting rod of the needle guide on its axis. The flywheel is simply stuck.

- The belt is too stretched or burst. In this case, the engine idles.

- The end of the needle broke off and blocked the shuttle, and with it the rest of the mechanism, up to the flywheel. The same thing happens when scraps of thread are wound around a shuttle.

By freeing all of the above parts from extraneous contents and lubricating them, you will achieve stable operation of the unit.

Other

Other malfunctions of the sewing machine include such.

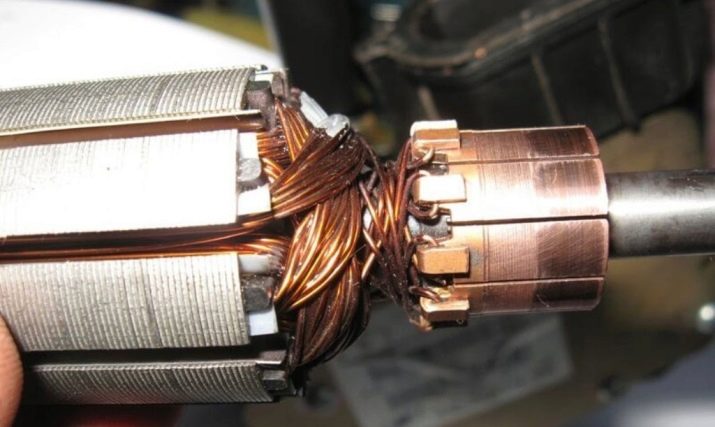

- Engine failure. Perhaps enamel insulation peeled off the windings, an interturn circuit occurred, and they burned from this. AC motors have been running smoothly for many years. But the frequent and lengthy work, from which they gradually warm up, sooner or later put them out of order. In the machine there is one such engine.

- One or more buttons does not work. Especially frequently used buttons break more often. Current-carrying contacts from several hundred thousand or millions of clicks will be wiped and oxidized.

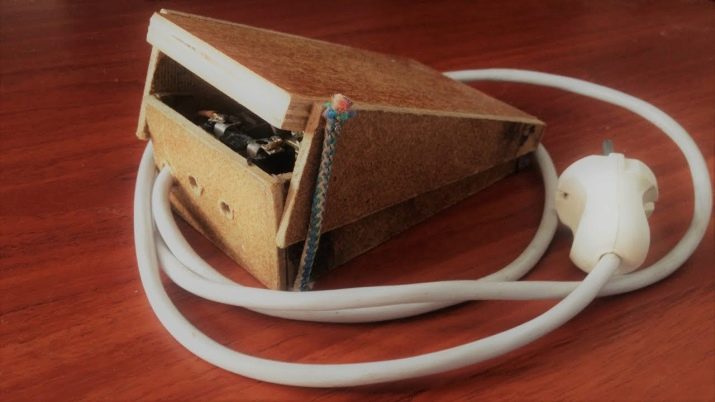

- Pedal failure - It is able to withstand more than one million clicks. However, sooner or later it will certainly be faulty, like any of the control buttons.

- The display does not work. For electronically controlled machines, the display may not be highlighted or display nothing (or display randomly, it is not clear what). The reason is the oxidation of the current-carrying paths and the gradual destruction of the loop supplying its corresponding sectors.

No matter how this or that malfunction manifests itself, it can be eliminated independently or contact the service center for repair of sewing and knitting equipment.

How to fix it?

Do-it-yourself sewing machine repair makes sense when you have at least the basic skills to restore the performance of the equipment. In this case, you will need the following tools.

- A set of screwdrivers, including three-and six-sided. In expensive electronically controlled cars, 5-sided screwdrivers (“pentoblocks”) may be required - as well as for repairing smartphones and tablets. The specific set of screws depends on the model - having removed the case, inspect all the connections and act on the situation.

- Set of wrenches. In cars, most likely, use small nuts - under 3, 4, maybe 5 or 6 mm, but no more.

It is advisable to use tubular - for access to buried connections.

- Motor or industrial oil.

- Consumables. Rate the situation. Any detail can break. You can order exactly the same from China - for example, through the online store AliExpress, or go to sewing workshops and shops, as well as the household markets of your city, region or region.

It is quite possible to fix the sewing machine yourself. For example, if the pedal fails - if you didn’t find a similar one or did not want to pay the masters from the service center, you will most likely make a similar one.

Making a pedal out of any powerful button or switch is not so difficult - in fact, it is a switch, a switch, a make contact.

It is possible to use anything - up to a room light switch with an enlarged contact area of a streamlined shape. Some make pedals for sewing machines, for example, from keys from old wireless telegraphs that used Morse code.

If you need to repair an electric drive in an electric (electromechanical) sewing machine, most often here we are talking about an engine, which may fail over time. The manual model does not have a motor. Rewinding engines is not a fast task, even if you turn to specialists who repair all kinds of components, which include windings.

In modern sewing machines, collector or stepper motors are most often used. The first ones work directly from a direct current source - for example, with a voltage of 12 volts. The second ones require the same voltage, but in pulsed mode, where a special adapter with a driver for the stepper motor is needed. Both can be ordered from China or purchased at the nearest radio market or at a radio store. Replacement of rubber belts is also carried out in the service center.

But the most "advanced" users can cut these gum, for example, from older cameras.

If the purchase of new needles and threads does not cause any difficulties, then the acquisition of spare parts from the shuttle mechanism will be more difficult. Shuttle parts are unlikely to be sold to you at the nearest sewing store - the shuttle is not so quick-change consumable that it can be changed literally at every step, which can not be said about the needles. This part costs tens of times more than all the same needle and bobbin for the lower thread - most likely, you will order this part on the Internet.

Choose stainless steel parts right away - It’s good when their source material is stainless steel.

But these same details will be immediately found in the service center - without the installation service, you are unlikely to receive them there.

You will be able to replace the display in a household sewing machine yourself only if you find the same on the Internet. SC workers simply have similar spare parts from exactly the same machines, in direct contact with their manufacturers.

Breakage prevention measures

To break the sewing machine as little as possible, Observe the following rules.

- Sew always on a stable and strictly horizontal surface.

- Do not store the product in heat, cold and damp.

- Regularly lubricate the friction surfaces of machine parts. The manual may indicate the total time of intensive operation of the machine in hours, after which it is simply necessary to clean and lubricate the mechanics of the device.

- Do not connect the device to the power supply, where voltage often jumps. It is recommended to use a filter and a stabilizer or uninterruptible power supply - it will protect the machine from power line surges.

- Do not neglect the machine setting when changing stitched material. After a long period of inactivity, verify that the specified characteristics are correct. For example, for different fabrics, use the appropriate thread and needle.

If you are working with a specific model for the first time (for example, you just bought it), check out the instructions, which also provide tips for servicing the product. Whatever the model of your device, it can in any case be repairable.

Remember that repair is an urgent need when normal maintenance revealed not just a temporary malfunction of the product, but a very real malfunction.

Observing safety precautions, following the above rules, you will achieve that even the cheapest device will last without problems for at least a few years.

You can get acquainted with methods of eliminating some types of malfunctions of sewing machines in the next video.