In the middle of the 19th century, it was not affordable for everyone to sew a thing on order or to repair it, since tailor services were expensive. Fortunately, a foot sewing machine appeared that made life easier for many housewives. Over time, she began to improve, which helped to create real masterpieces.

History

A foot sewing machine has not many functions and lines to use it in special ateliers. But for working at home, such a machine was the best option. Working with a foot drive, the hands remained free, which allowed to speed up the sewing process and improve the quality of the product.

It is known that the creator of this model was Isaac Singer. It was he who made the tailors able to move the fabric in different directions and create unusual seams. With the advent of the foot drive, the seams began to turn out longer, which accelerated the work.

It was also known that before Singer there were other creators of sewing machines with a foot-operated drive, but they never made history. The fact is that for the official approval of the manufacture of machines it was necessary to pay for a patent, which Isaac's predecessors did not do and became supporters of the creation of new models.

The developer of the machine made the needle move vertically, and not horizontally, as it was in previous models. Then he improved the device with a special foot, which was held by the gear. Due to these mechanisms, the fabric was fixed and freely moved in the direction in which the tailors would direct it.

3 years after the creation of his first model, Singer founded his company, where advanced models were already created, with which it was possible to perform complex seams and do it much faster. Over time, cars began to be sold in installments, this was done so that not only rich but also ordinary people could afford them. That is why the company gained immense popularity, and a few years after the opening of the first factory, others appeared, moreover in different countries.

It is worth noting that Isaac did his best: after all, the first mechanical foot-operated sewing machine appeared in the middle of the XIX century, and some models still work.

User's manual

Many housewives have foot sewing machines, but not everyone knows its instructions for use.

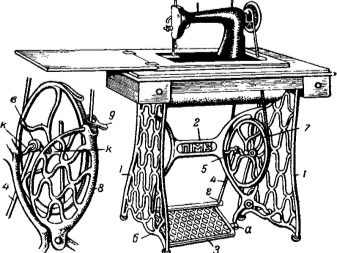

- First you need to get the machine itself, which is built into the cabinet. To do this, the front valve rises, the head of the machine is pulled out, and so that it is stable, the valve is lowered.

- There is a trigger wheel rim that goes with the gutter. A round belt is put on it, connecting the flywheel pulley to the starting one. Due to this, rotation occurs.

- In the process of work, you should constantly press the foot pedalsdue to which there is an oscillatory movement. Thus, the connecting rod and crank begin to rotate, they, in turn, use the starting wheel.

- To thread the thread, you need to rewind it from spool to bobbin. To do this, the coil is mounted on the top pin of the machine. Next, thread the upper thread, thread and pull the bobbin thread. Finally, the upper and lower threads need to be wound by the foot.

When working with such a machine, it is worth observing the safety rules.

- Constantly monitor the movement of arms and legs. If the movements are not synchronous, then you can ruin the material.

- After completing work, the belt must be removed using a special cutoff, and It can only be worn before sewing starts. In the process of work, it must not be held in order not to get injured.

- When threading the needle, you should monitor your legs - they should not be on the pedal.

If you follow all safety rules, then the finished thing can be sewn in a short time.

At first it will be quite difficult for a beginner to work on a sewing machine with a foot-operated drive. therefore To learn how to control the movement of arms and legs, for a start, it is worth learning to idle, that is, simply practice the movements of the pedals.

Repairs

The foot sewing machine is rather bulky, and in case of breakage it is inconvenient to drag it to the workshop. Therefore, those who still use this model should know how to repair it at home.

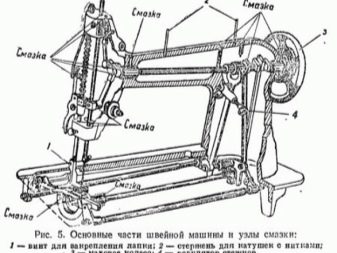

- Screw loosening. The first step is to loosen the locknuts - an open-end wrench will do. Then, with a conventional screwdriver, you can proceed to unscrew the screws. If the repair has not been carried out for a long time, then a hexagonal key cannot be dispensed with, since the screws are most likely well attached to the bed due to oil and dust. The next step is to thoroughly clean the conical plane of the screw, grease it and put it in place.

- Node adjustment. To get rid of the knock that comes from the foot drive, you need to tightly clamp the cone. Do not tighten too much, as the problem may appear again. If, after clamping the cone, the knock does not disappear, it may come from another node located in the center of the flywheel, where the belt is attached. This assembly must be disassembled carefully, since there is a bearing on this hinge. If it is whole, then you just need to lubricate it with special grease by adjusting the clearance. Otherwise, the bearing will have to be replaced with a new one.

- Replacing drive belt. Over the years of operation, the belt wears out, so it often breaks. This belt is made from rawhide, but you can replace it with a regular clothesline or leather belt.If you do not want to bother, then the belt for the foot drive can always be bought in a special store. If the belt is torn, but the item is not finished, then it can be fastened with a paper clip.

In fact, everything is very simple, so with any breakdown you can always cope on your own.

Varieties

There are several well-known models of foot-operated sewing machines.

Finger

These antique models were the first to use a foot drive. They say that precious metals were used to make them. By the way, if someone has such copies, then you can check whether there is real metal. To do this, bring the magnet to the metal frame. If the magnet does not stick, then there really is a precious metal (gold, silver or palladium). The cost of Singer sewing machines is high, but many purchase them to complement the retrostyle.

Soviet cars with a curbstone

In the USSR, various versions of machines with foot drive were manufactured. Such a model is convenient in that in a room, it can come in handy as a regular table. And if you need to sew something, then the cabinet can easily be decomposed. And also in it you can put everything you need for sewing.

By the way, a foot machine with a pedestal handles various types of fabric (linen, wool, synthetics, silk) and performs 2 types of stitches - straight and zigzag.

Sewing machine brand "The Seagull." She performed only straight and zigzag lines. She did not enjoy great popularity, since there were her drawbacks - the lack of a special return lever.

The famous Soviet model "Podolsk" was the favorite of many seamstresses. In addition to straight and zigzag stitches, it was possible to sew decorative stitches.

Orsha

A feature of the Orsha models was centralized lubrication and semi-automatic winding of thread on a bobbin.

Butterfly

This model is Chinese-made, but it could be purchased in any city of the USSR. This Chinese machine looked like a table with two drawers. She was a complete analogue of the first Singer machine.

To date, foot-operated sewing machines can only be purchased at antique stores or from someone in-home in a used condition. But, despite the fact that models of sewing machines are improved every year, complex lines can also be performed on mechanical machines. The main thing is to be able to correctly press the pedals and control the movement of arms and legs.

To learn how to learn to sew on a foot-operated machine, see the next video.