Uniform and high-quality stitching of seams at any time can be complicated by the appearance of extra knots, irregularities on the stitches, layering them on top of each other with a violation of the smoothness of the stroke.

Bobbin winding

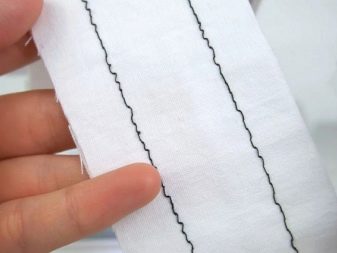

An ideal seam is a line in which there are completely no loops creeping out onto the surface of matter from either side. The establishment of the upper thread for the lower thread at the joints of stitches is made approximately in the middle of the thickness of the layer (or several layers) of the material. Loops going up indicate looping of the bobbin thread, and vice versa. The reasons why the machine winds are as follows.

- The thread on the bobbin is wound in bulk. Because of this, its tension fluctuates sharply and randomly. The seam in this case comes out ideal in some areas, then the upper thread is visible from below, then the lower one from above. Use a standard thread winder. If you work with a single-thread sewing stapler, you can make a bobbin winder based on a small battery or battery motor.

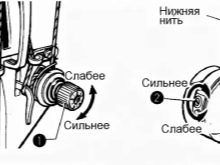

- The bobbin thread tension is insufficient. The slot in the plate of the shuttle mechanism is incorrectly set. You will need to configure the shuttle itself. Changing the thread (thickness, material), adjust the shuttle itself. Check that the bobbin thread is wound with a little effort.

- The upper thread is too tight. Adjust its tension with the knob - it is marked with numbers on the dial. Set the correct value - it must correspond to the thread itself and the performance of the stitched material.

- The bobbin has chipped, notches. The plastic bobbin is deformed. Change it to one that will not let you down for years.You can grind the burrs with a file with a finely abrasive surface or the same sandpaper, remove the burrs with a particularly hard knife (for example, a scalpel). It happens that the damage to the bobbin is so slight that smoothing them is not difficult. If the cap and the bobbin itself are thoroughly beaten - in notches and potholes, then change these components. Bobbins and caps are often sold in a specialized sewing store, which is sure to be found in every more or less large city.

Perhaps, after all these checks and actions, the machine will again work properly, without deviations.

The machine chews the thread from the bottom

The confusion about missing the bottom thread is due to a number of reasons.

- The thickness of the needle, thread and stitched material do not match each other. A needle that is too thin will become stuck in thick tissue. A thread that is too thick passes through the eye of the needle with great effort. Excessively thin material for a thick thread and a thin needle will lead to the formation of large holes in which the stitches can fall out, “pull up”, the seam will immediately change its evenness and impeccability.

- A dull needle tears tissue. Twisted and nonsmooth thread twists right there, forming nodules already when stitching.

- The gear rack is not properly aligned (as indicated in the instructions) in the area of the teeth or lintel. The teeth on the rail became dull, she suddenly began to shift in the wrong direction. Most often, the latter happens when the needle has passed through the matter for the first time, and the shuttle responded.

- Thread tensioner defective or incorrectly set.

- The bottom of the sewing foot is broken or has a defect. The foot itself is excessively weakened and loosely clamps the fabric, due to which it slides in different directions.

- The bobbin hangs in the cap, “walks”, because of which the tension of the thread can also change in a “jerky” rhythm. Either the cap retainer with the bobbin is broken, the bobbin is loose or completely falls out.

- Friction washer incorrectly installed on the main drive wheel.

- The thread tension does not match the thickness, stiffness stitched matter.

- The bobbin thread coming from the bobbin to the shuttle suddenly broke. Before this, it can rush around the entire bobbin (for example, if it is wound randomly), and the formation, retraction of the formed loops of this thread into the fabric stops abruptly.

- The needle plate gap is not set correctly.. In this case, the stroke of the needle, its passage through the tissue has a deviation from the norm.

- The upper thread itself is incorrectly threaded. The sequence shown in the instructions is not followed.

- In the manufacture of the thread is not twisted to the left, but to the right. The “right” thread is often twisted in the wrong place, which is why the stitches are confused and layered on each other, turning into something remotely resembling a ball of thread.

- Unsuitable reels or reelstrying to use thick and tall bobbins for a sewing conveyor on a simple home typewriter.

- During the sewing process, you pull up, push the fabric by hand, as if forcing the machine to accelerate and sew faster. It's impossible. Each machine has its own bandwidth (the number of stitches per second, minute) - do not try to “fool” a well-tuned and debugged mechanism. By practicing pushing and pulling matter, you risk tearing the fabric, tearing one or both threads.

Other reasons may be related. with wear, the final failure of certain parts of the machine. Replace worn items. You can execute it as yourself, by finding the necessary part (or several parts) in the online store, or in the market in your city or region, or immediately contact the service center engaged in the repair of sewing and knitting equipment.

In electronic machines, incorrect operation can also be triggered by the failure or inadequate operation of the ECU board.

Bottom Thread Adjustment

So that the lower thread does not get confused, forming a bundle, and does not crawl up, did not form knots of stitches overlapping each other, perform a series of actions.

- Check that the upper and lower threads are threaded correctly. If you notice inaccuracies or when there is no time to figure out where what was missed, pull the upper thread and thread it again, carefully following the sequence for threading it. The sequence of threading the upper thread is most often as follows: the upper thread guide - the first part of the channel to the tensioner - the tensioner itself - the second part of the channel to the second thread guide - the turn of the thread on it - the third part of the channel (if any) - the drain loop on the needle bar - needle eye - slot paws. Then take the thread to the side. Set the tensioner to the desired value using the knob on which the digital dial is applied.

It is useful to take advantage of previously made marks - which thread and which fabric, which needle matches the value on the tensioner adjuster.

- For the lower thread, pull out the cap with the bobbin by lifting the shuttle plate of the shuttle compartment. Check that the thread on the bobbin is wound evenly and gently, that the thread itself does not end (the bobbin would be almost empty). Re-insert the bobbin into the cap and turn the tensioner screw with a screwdriver - the thread should be wound with a little effort. Make sure that you use a smooth and elastic thread - a coarser one, for example, made of hb fiber, would leave “combed” in the tensioner and clog it over time. Insert and lock the cap with the bobbin - a click will be heard when fixing. Make sure the bobbin is seated securely and does not hang in different directions.

Pass the end of the thread through the gap in the needle plate, extend the end by 10-15 cm, bend it by the slot of the foot and move it to the side along with the end of the upper thread. Now try to sew an approximate seam on the test patch. Its quality (lack of confusion and chewing threads, skipping stitches) will immediately be noticeable.

If nothing helps, change the tension of the upper and lower threads until you achieve the optimal result.

Conclusion

There are times when even the most careful tuning and debugging of the machine will not give the desired result - and you still have not achieved the quality of the seam, no matter what you do. The only way out is disassembling, cleaning and lubricating the sewing machine. Defective (wear, oxidation, breakage) parts should be replaced as soon as possible.

What to do if the bobbin thread is wound around a bobbin or wound, see the next video.