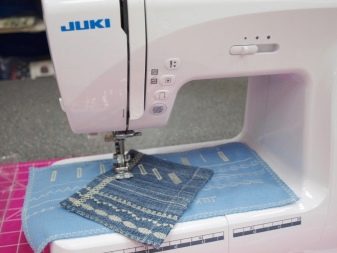

Sewing machine - a technique that can be found not only in sewing studios, but also in almost every apartment. Self-production of clothes and textiles is one of the most popular hobbies, which makes it possible not only to significantly save the family budget, but also to realize all design ideas. For the smooth process of making clothes, it’s not enough to have only sewing and tailoring skills - you need to know the design features of the sewing machine, which will help in case of breakdown to quickly eliminate all malfunctions.

One of the main elements of the sewing machine is the shuttle. It will be discussed in our article.

Description

The shuttle for the sewing machine is an important element, the quality of sewing work depends on the accuracy of its interaction with the needle. If the shuttle device works correctly, then there will be no skipped stitches, breakage of the upper and lower threads, and also no winding of the thread from the bottom.

In order for the device to work perfectly, its surface should not have scratches, mechanical damage, traces of corrosion, dust and oil residues that will prevent the thread from slipping and provoke the stretching of the upper yarn, which will lead to a weak tension of the stitch.

On the shelves of specialized stores you can see a wide range of sewing equipment, the design and functional features of which depend on the type of shuttle device.

It is precisely this feature that you need to pay attention to when buying, and before you go to the store, experienced seamstresses recommend carefully studying all the advantages and disadvantages of each model.

Principle of operation

The shuttle operation mechanism directly depends on the design of the sewing machine.

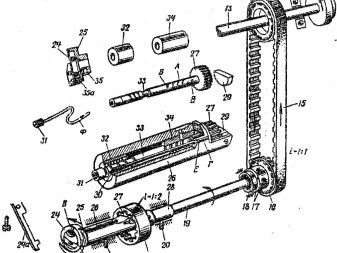

The principle of operation of a classic vertical device is in the placement of the bobbin with consumables in a special bobbin groove, in the process, the device begins to move in horizontal and vertical positions, dragging the thread along with it. This mechanism has a high level of reliability due to the rigid connection of the lever and the body of the machine.

The mechanism of the vertical rotation mechanism is in movement of the bobbin case with the bobbin around its axis. Depending on the operating speed used, the device can rotate at a speed of about 900 revolutions per minute. The reliability of this device is due to the quick setup of the shuttle and its optimal location relative to the needle shaft.

The principle of operation of the most common horizontal mechanism is to form a stitch only after the shuttle completes two full turns. The simplicity of refueling consumables is due to the presence of an integrated bobbin case in which a glass spool of thread is simply inserted. The operation of this device is as quiet and silent as possible, and all mechanisms are lubricated automatically.

Which type is better to choose?

Depending on the model, sewing machines have different types of shuttles.

Varieties of shuttle mechanisms:

- horizontal;

- vertical;

- swinging;

- rotary.

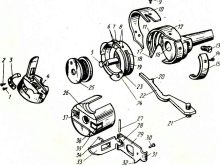

A swinging (pendulum) shuttle is the most common type that is installed on inexpensive and old models. If the seamstress plans to constantly operate the sewing machine, then it is better to refuse to buy a device with a swinging shuttle. Advantages - reliability, unpretentiousness, durability, low price range, resistance to overloads. Disadvantages - low speed of work, the presence of noise and vibration during sewing, a small number of lines.

The horizontal shuttle is a modern device in which the bobbin is located on top. This mechanism is the most convenient in operation, and its upper part can be seen through the window of the needle bar. The horizontal arrangement of the bobbin makes it possible to control the operation of the part and the amount of consumable on it. Distinctive features are ease of use and the absence of a bobbin case, which replaces the built-in black plastic part. It is in it that the master inserts the bobbin. To prevent the appearance of cracks and ditches, experts recommend using only thin, elastic and durable threads. Advantages:

- low noise and vibration;

- obtaining an elastic and high-quality stitch;

- lack of distortion when adjusting the seam width;

- simplicity of gas station and operation;

- the ability to perform various types of seams.

Disadvantages - the high cost of repairing the elements of the bobbin case, the complexity of the settings, breakdowns when the device is overloaded.

The vertical rotary shuttle is a special mechanism that is used only for industrial equipment, as well as in expensive multifunctional sewing machines. Advantages - high speed, high level of resistance to wear, high quality of the weld. If during installation of the mechanism all the requirements and norms were met, the product can uninterruptedly last a long period of time. Using a rotational shuttle mechanism allows you to work with almost all types of fabric, and also eliminates the likelihood of entanglement of the lower thread.

An important advantage of the device is the presence of a large number of types of lines that can be used for both domestic and industrial needs.

The type of shuttle installed directly depends on the class of the sewing mechanism:

- budgetary - vertical swinging;

- middle - horizontal;

- expensive and industrial - rotational.

The choice of equipment type is directly influenced by the professional experience of a seamstress:

- complete lack of professional skills - simple equipment with a pendulum mechanism, which has limited functionality;

- basic knowledge - advanced equipment with a horizontal shuttle, which will allow you to work with different types of tissue density in moderate mode;

- high professional level - multifunctional equipment that has a wide range of lines and is used in specialized sewing workshops.

Choosing a shuttle mechanism, special attention must be paid to the manufacturer. Experts do not recommend purchasing cheap goods from Chinese companies that do not have quality certificates and permits. But on the goods of European manufacturers made in China, you should pay attention. Despite the affordable price range, they have a high level of reliability and quality.

Most workers in the garment industry prefer horizontal and rotary mechanisms, which are distinguished by a wide range of options and a long period of operation. The choice of devices depends on the planned intensity of the work.

Obtaining a high-quality and beautiful line will help expensive models, it is also necessary to carry out professional equipment setup, which will guarantee the expected result.

How to install and configure?

Setting up and adjusting the sewing machine are important activities that directly affect the operation of the equipment.. Before proceeding with these manipulations, it is necessary to study the instructions in which the manufacturer indicates all the necessary parameters of the device, as well as the rules for use, setting up the machine and how to assemble all its elements.

In order to properly install the shuttle, you must perform the following activities:

- installation of the device in the required position;

- turning the handwheel of the machine along the sewing stroke until the moment of maximum lowering of the needle shaft;

- connection of the end of the shuttle and the middle part of the needle;

- fixing screws in the exposed position;

- fixing the needle rod.

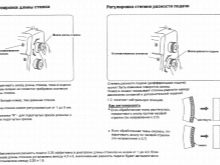

In order for the sewing machine to work without failures and problems, experts recommend that special attention be paid to the interaction of the shuttle and the needle, namely the distance between them, which must comply with the established standards. If the size range is not respected, the following problems may occur:

- skipping stitches;

- looping threads;

- breakage of the upper and lower consumables.

To conduct high-quality tuning work, experts recommend that you carefully study the principle of loop formation from the very beginning. While raising the needle rod to a height of not more than 0.2 cm, a loop is formed from the upper yarn, which is located above the needle ear. An important point is the mandatory passage of the end of the shuttle as close to the needle cavity.

The optimum distance between parts is 0.16 mm. The gap from the end of the hook to the eye of the needle should not exceed 0.6 mm. These values are basic and may vary in accordance with the type and thickness of the fabric. The practical advice of specialists and practical skills will help to choose the correct gap length.

Depending on the purpose of the work, the setting can be preventive and to eliminate the breakdown. Specialists distinguish the following main tuning stages:

- removing the needle plate;

- cleaning shuttle teeth from dust, dirt and sewing residues;

- establishing the necessary gap between the end of the shuttle and the needle;

- setting stitch length;

- replacement of the sewing needle if necessary;

- adjusting the rigidity of the screw;

- lubrication of working ribs with special paste.

If these manipulations did not help set up the device, then experts recommend putting the machine on its side and carefully inspecting the following elements:

- running parts;

- heel;

- nose;

- ribs.

If during the inspection a loss of sharpness of the nose was revealed, then experts recommend simply replacing the part. Self sharpening will certainly provoke a rupture of stitched fabrics.

Particular attention should be paid to setting up the device, which was idle for a long time, which can provoke not only the accumulation of a large amount of dirt, but also the appearance of corrosive deposits.

After setting up the device, experts recommend conducting testing the shuttle for lubrication. To carry out this manipulation, it is necessary to remove the needle plate and foot, and in their place place a small sheet of white paper and immediately start the machine for a few seconds at maximum speed. The equipment has a sufficient amount of lubrication if two vertical lines remain on the sheet. Excessive amounts of lubricant can cause product contamination, and lack of oil will lead to premature wear of parts.

Possible malfunctions and their elimination

Despite the professionalism of the seamstress and the reliability of the device, in the process of intensive work, a number of malfunctions will surely arise, some of which can be eliminated independently, but to solve other problems, you must resort to the help of specialists.

The most common problems and their solutions:

- gaps in the line - adjustment of the looper, checking the height of the needle;

- weak or strong thread tension - adjustment of the shuttle and tension plates;

- complete lack of lines and the presence of extraneous sounds - mechanical breakdown of the shuttle;

- sloppy stitching - setting the same tension of the upper and lower threads.

Often, beginning seamstresses are faced with the fact that the upper thread is wound. This malfunction indicates that the bobbin is not correctly positioned in the hook. Failure to fix the problem can lead to damage to the machine.

To minimize the number of breakdowns, experienced seamstresses recommend observing the following recommendations:

- regular lubrication of equipment - at least 2 times a year;

- thorough cleaning of the surface of the device after each use;

- daily check of lubricant level;

- flushing the device with gasoline or kerosene without removing it from the machine;

- use only high-quality, certified fluids for lubrication;

- Before closing the cover, it is necessary to remove all residues of consumables, and put a small piece of cloth under the lowered foot;

- long-term storage of the device is unacceptable without a cover;

- during the storage of electrical cables, it is necessary to regularly check for bends and kinks that can lead to deformation of the wires;

- flywheel rotation only towards you.

Monthly must be carried out complete cleaning and thorough inspection of the shuttle and bobbin. Particular attention must be paid to the channels through which the lubricating oil flows - they must always be clean. If traces of contact with threads were noticed on the surface, then minor damage can be cleaned with fine sandpaper.

It is strictly forbidden to use force during the operation of the machine, to pull the material strongly towards you, and also to lower the needle shaft onto an empty plate and continue sewing with the presser foot raised.

Sewing is a fascinating activity that allows you to not only make textiles on your own, but also to fully demonstrate your design abilities. A sewing machine, regardless of brand and model, will certainly become an indispensable assistant in this process.

How to choose a shuttle for a sewing machine is described in the next video.