Sewing complex and thick fabrics requires the use of a particularly powerful and productive technique. Properly selected needles, special paws and a wide range of functions are what you need to work with drapes, jeans and other especially dense materials. Sewing machines for leather, eco-leather, dermatine should not crumple the surface, promoting the future product on the bed. Most often, they are used by professionals in line production. Household models usually do not have an electric drive, and in general are somewhat different from those that are designed to work with light materials.

The choice of a manual machine for sewing leather and heavy fabrics, core, household and other types implies a thorough study of its functional equipment. Precisely, inexpensive, budget models designed for low-density materials will definitely not work. In addition, for working with fabrics of various types it will take a lot of additional devicesfacilitating the achievement of the result. Let us consider in more detail what equipment is needed for individual sewing of leather goods and clothing.

Features

How does the sewing machine for leather or for heavy fabrics differ from ordinary models, let's understand. Among its main features, one can note the ability to hold and promote thick matter without crushing it. To do this, there are special conveyors and legs that can cope with the most difficult tasks. In addition, the machine for thick fabrics - drapes, jeans, leatherette should provide good quality stitches. Professional devices for performing highly specialized tasks are usually single-needle.

Designed for sewing in continuous mode the most powerful, productive equipment. She has a special table - stand for work, backlight, frictional type electric drive.

Household machines are also available for dense fabrics. But not every one of them sews fabric with a thickness of more than 5 mm.

By the type of drive, sewing machines for leather are mechanical, electromechanical, computerized - with intelligent control. For beginners, the microprocessor will be an unnecessary option. But for experienced craftsmen, this option will significantly expand the capabilities of technology. A useful feature would be a reinforced needle puncture, allowing piercing even thick skin. If a model with an electric drive is selected, it must have a power of at least 100 watts.

Advantages and disadvantages

The advantages of special machines for sewing leather and thick fabrics include:

- high performance;

- high reliability;

- slow wear of components and assemblies;

- accurate calculation of characteristics;

- adaptability to work with materials of different densities;

- the ability to create straight and curved seams.

By cons include significant noise during the operation of industrial machines and the rather large weight of such equipment. Household mechanical options require regular maintenance. In addition, many professional models have a highly specialized focus, and you cannot use them for ordinary sewing. A significant disadvantage is the high price.

If you do not plan to start in-line production, it is better to get by with budget options that have a wide range of applications.

Varieties

All varieties of sewing machines for working with leather can be divided into 2 large groups: household and industrial. Almost all manual models with a rather heavy base belong to the first category. In addition, for household sewing machines suitable for sewing leather, the following parameters are important:

- powerful drive;

- stitch length more than 6 mm;

- metal, reliable components;

- high elevation of the foot.

The simplest example of household manual equipment for sewing leather is "Podolsk." This is a class 430 machine that allows you to work with leather goods, shoes, bags, belts. But modern manufacturers offer no less functional options equipped with an electric drive.

Industrial machines also vary in class. For leather, models 22 and 1022 classes are used, as well as 23 classes with an electric drive, household and industrial, at 380 V.

Sleeve machine

A professional variety of sewing machines equipped with a roller element for feeding material and conveyors for synchronous operation. The sleeve platform is often part of classic household models, and is hidden in a conventional bed. Industrial machines are distinguished by the fact that they can stitch edgings and trim the edges with tape.

Among the main parameters that you need to pay attention to when choosing a hose technique are the length of the sleeve element used to feed the lower thread and the diameter of the bobbin used here.

These machines are widely used in the field of repair, and individual tailoring of shoes, but when working with bulk pieces of material, they are not too convenient.

Core machine

Single-needle core sewing machines for leather belong to the category professional, highly specialized equipment. Their design uses a small diameter column mounted above the needle holder, which allows you to work with small, curly objects, shoes, suitcases, and large-format wardrobe trunks. Such industrial machines are expensive, but they fully pay for themselves in the conditions of continuous production.

When sewing on a core bed, the material is worn directly on it, like a cover. Such models are especially convenient for flashing complex areas, curly elements, where it is important to control the quality of the line. With their help, you can combine the elements and parts of the product in different planes.

The rotating platform and the small diameter of the column make this machine convenient for working with any volumetric products. It surpasses sleeve options in functionality and is necessary for sewing bags, wallets, gloves. In such a model there must be a horizontal rotary shuttle, a roller feed of material, a double or triple conveyor, an automatic lubrication system.

It is worth considering that the bottom thread feeding device in such models is located inside the column.

Accessories

What elements and accessories are necessary for effective work with leather or other thick, dense materials? Among the required accessories, one can definitely note special pads, complemented by rollers or rollers, to avoid hitches and damage. To facilitate the movement of material, it is sometimes additionally used a strip in the form of a thin strip of paper, which is then simply removed.

The best material for non-roller paws with a walking design can be considered Teflon or fluoroplast.

The needle number and its shape also matter. It uses strong steel that can cope with ultra-high material resistance. The needle when sewing the skin does not pierce, but cuts the surface, and should have a peak shape. Suitable numbers range from 90/14 to 110/18. In the shape of the needle are:

- oval (right, left, longitudinal, transverse);

- trihedral;

- square (longitudinal, transverse).

When choosing threads, you need to give preference to the most durable options from a thick multilayer nylon. The thickness is determined based on the characteristics of the selected material. And also when working, it is recommended to use a special cutting tool - a cutter with replaceable blades, or a knife for cutting leather. It is recommended to process the allowances on the skin with rubber glue.

In addition, when working with dense materials, it is recommended to use special tools for attaching accessories.

The best models

To work with leather on the modern market there are several models of sewing machines.

- Brother S-1000A-5. Sewing machine of a professional class. Designed to work with materials of medium and high density. It surpasses most other models in characteristics.

- Jack JK-6658. Industrial machine for creating straight stitches on canvas, thick leather. The model provides a walking foot, a needle of high strength. The pitch of the stitch is limited to a limit of 7 mm; the speed reached 2000 rpm.

- Vista SM-245. Industrial-grade single-needle machine. Included is a flat platform, a fairly powerful motor that allows you to develop a sewing speed of up to 800 rpm. The reverse sewing function is supported.

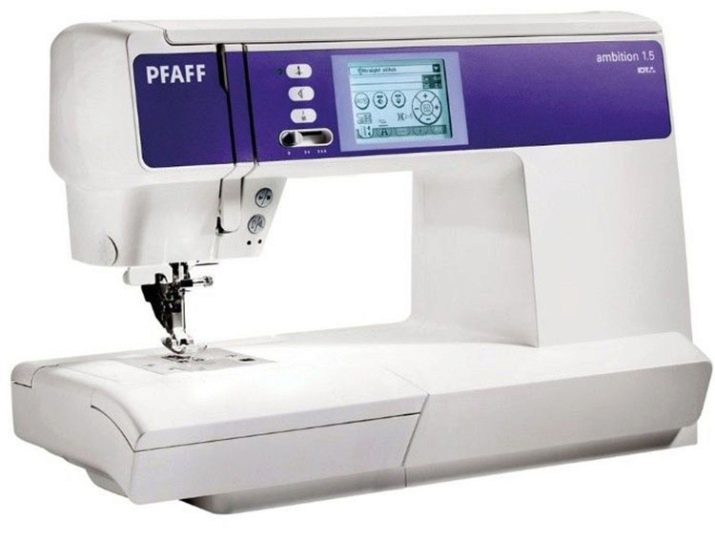

- Pfaff Ambition 1.5. A machine from a German brand, manufactured in Taiwan. The model has a fully computer control. The set includes a foot pressure regulator, an upper conveyor, support for 195 operations, an electronic adviser, and a sewing speed controller.

The machine is quite simple to use, does not require much experience, can be used without a pedal.

- Toyota OEKAKI50 Renaissance. Simple and reliable equipment of the Chinese assembly from the Japanese manufacturer. The model is equipped with a special foot that allows you to sew suede and leather, in the presence of a needle threader, automatic buttonhole stitching, 50 work programs of varying complexity.

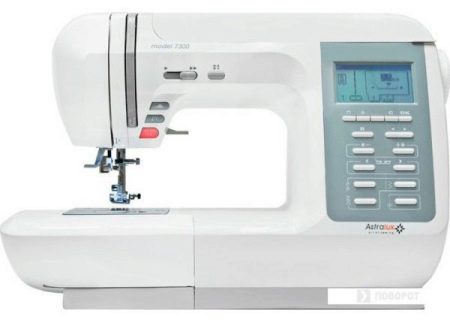

- Astralux 7300 SE. The sewing machine of a household class, supports the implementation of 504 operations, including sweeping 13 types of loops. When working with leather, it is worth considering the restriction on the thickness of the material, use special paws.

A large number of functions can significantly complicate the process of working with equipment.

- Janome 743-3. Sewing machine household class, the main components are made of plastic. Only suitable for sewing thin skin, dermatin, eco-leather.

Beginning seamstresses may come up with a budget solution - sold in the secondary market model "Podolsk 34" 330 class. It is no longer produced, but such a machine will cost inexpensively, and is suitable for working with leather, raincoat fabric, jeans, and drapes. More modern option — Podolsk 430 class It is widely used today in the field of sewing and repairing leather products, including haberdashery, shoes, accessories.

How to choose?

When choosing a sewing machine for working with leather, you should pay attention to a number of parameters that are of the greatest importance. For example, when working with skin the conveyor shutdown function is required. Besides, the design should have a walking foot, necessary for easier movement of material of increased thickness, or pinch roller. Required in industrial and domestic machines stitch parameter adjuster, standard range from 6 to 8 mm.

If special needles are not included in the package, be sure to take care of their purchase.

The power of the machine should be higher than that of ordinary household versions. The height of the foot when working with the skin usually exceeds 8-10 mm, it is worth paying special attention to this. All components, including gears and other rubbing parts must be metal - plastic will not withstand the workload. When selecting, you need to remember that the mass and dimensions of specialized machines for working with leather products are always higher than those that are designed for light fabrics. In most cases, you have to purchase a special stand or table to place them.

Do not assume that cheap low-power Chinese-made machines will be able to provide sufficient performance when sewing leather or thick materials of high density. If you plan to seriously engage in work with such products, you will have to invest in the purchase of reliable and functional equipment. The average cost of a household leather machine starts at 35,000 rubles.

How to use?

Working with a sewing machine for genuine leather requires following certain recommendations. In particular, you need to abandon the chipping of layers of material with pins or other sharp objects. In addition, soft skin and its substitutes can be sewn with needles of numbers 80 or 90 for ordinary machines. Thicker and multilayer materials will have to be processed using special tools. Needles with a spiky point are required here.

When sewing leather it is important to set the stitch length to at least 6 mm, in this case, the material will not crack at the puncture sites. If you have to work with suede, and other fleecy materials, you must definitely keep a seam in the direction of the pile. To avoid stretching the upper part relative to the bottom, you can use the foot having a Teflon-coated sole. In the absence of a reverse function, the ends of the stitch are tied manually, in several knots.

When choosing seams for the skin, it is worth giving preference to seam, seam, and stitch seams. Allowances are fixed with glue. Preliminary estimate is not carried out.

See how to choose a sewing machine for leather in the next video.