Sewing machine refers to sensitive household appliances. A small violation in the functioning of its parts can cause a malfunction or breakdown of the unit. For this reason, the responsibility of each owner of this device includes its maintenance. How to clean the sewing machine?

Operational Features

If malfunctions were noticed during the use of the sewing machine, namely skipping stitches, lack of work with fine thread, deformation of the fabric, then it is time to carry out a technical inspection of the unit. The correct care of a device of this kind includes timeliness of cleaning, as well as good quality lubrication. Subject to these conditions, the user can count on the long and uninterrupted operation of the equipment.

During operation, a large amount of dust may collect over the shuttle and near the engine. Garbage particles also contaminate other parts of the sewing machine. For this reason the owner should wipe the mechanism free of dust. Also do not forget about cleaning grease holes. At a time when the sewing unit is not used and has been idle for a long time, it must be covered with a cap or cover.

Cleaning

The most common cause of a broken sewing machine is clogging of its internal mechanism. The consequence of ignoring contamination can be jamming of the mechanism. In this case, wiping the casing and the unit regulator with a cloth is not enough. The user will have to eliminate all the fibers, thread particles, pieces of material from all internal elements of the equipment.

The procedure does not mean anything complicated, therefore It is advisable to carry it out every time after sewing. If the equipment is rarely used, then care for it can be carried out twice for 6 months. Work with knitted, fur, and woolen products more pollutes the parts with fibers that clog the mechanism.

Step-by-step procedure for cleaning the sewing machine:

- turning off the unit from the mains, removing the needle for safety;

- unscrewing the needle plate, disassembling the shuttle according to the instructions;

- purification from dust of a niche located under the needle plate;

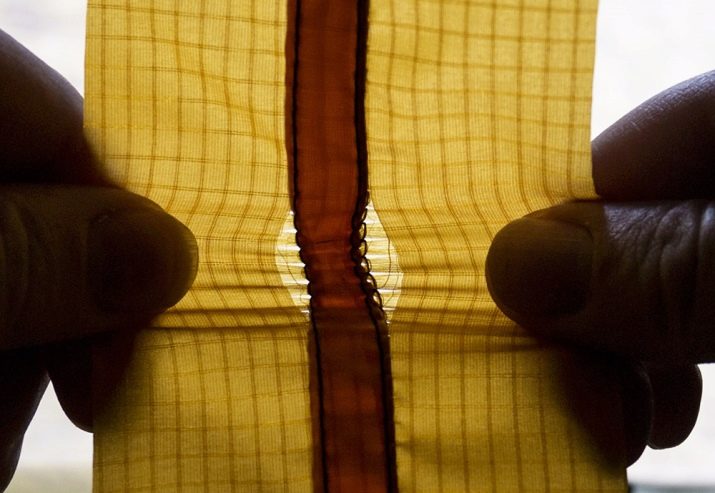

- cleaning the shuttle, as well as the bobbin case;

- elimination of wound strings, tissue pieces with tweezers;

- Using the blunt end of the needle to remove dusty aggregates in the corners.

Clean the sewing machine only with a dry cloth.

When using a wet cloth, rust may develop inside the mechanism. Dust is best removed with brushes. In this, it is better to use a soft brush to work with complex parts, for example, a shuttle. Untimely cleaning of the machine can lead to a malfunction of the mechanism, which is responsible for the movement of materials.

Also, contaminated equipment is an additional load on the drive, which entails a lot of problems and malfunctions. To rarely clean the machine, it should be kept in a case, so dust will be difficult to get inside the unit. For added security, niches under the needle (under the presser foot) are recommended to lay a strong, thick cloth that can close the needle hole.

Grease

People who do not use the sewing attachment all the time can lubricate it once every 6 months. Modern types of equipment need this procedure for preventive purposes, namely, to increase the operating life and more established work. This nursing event can provide the following:

- lack of need for frequent repairs of the machine;

- silent operation;

- smoothness and ease of movement of each of the moving parts of the unit;

- high quality products;

- simplicity of setup and adjustment.

The basic principles of lubricating a sewing machine are as follows.

- The unit must be lubricated only after thorough cleaning, which includes not only the elimination of dust and debris, but also rust, obsolete oil from the internal parts. The latter are removed with a dry cloth and raising the plastic casing.

- To carry out this procedure is strictly guided by the instructions for the purchased sewing device. It indicates how the structure should be lubricated - manually or by dripping oil into a special hole.

- For lubrication of the sewing machine, use only specially designed machine oil. To buy the substance is in the store.

- After lubricating the elements inside the device, it is worth turning the flywheel twice on itself, this contributes to a good distribution of the substance on the inside of the unit. Immediately better not to use the machine, as you can stain the processed material. According to the advice of professionals, it is worth equipping a kind of oil duct from a material that will drain excess substance.

It is periodically necessary to lubricate the controllers of the sewing machine, since their base of metal begins to rotate poorly and rust over time.

Professional Tips

In order to clean and lubricate the sewing machine as efficient as possible, It is worth listening to the following recommendations:

- Do not lubricate the equipment without prior cleaning, as dirt and dust in a sticky form can cause serious damage;

- not to get from felt and felt gaskets that are in them;

- more thoroughly clean the area under the plate - material conveyor;

- eliminate excess oil;

- Do not use car and vegetable oil for the sewing machine.

Despite the ease of maintenance of the sewing machine, it is periodically recommended to send it to a service center for professional diagnosis. There, craftsmen will be able to replace parts that are worn out and adjust the technique. Care for the sewing machine is necessary from the first days after its purchase. Before using the equipment or repairing it, you should carefully read the instructions.

Users should not think that the new unit will be able to work for more than a year without maintenance.

If the machine has stood idle for a long time, then without cleaning and lubrication it is not worth starting sewing.

It is best to store this type of equipment in a dry room, which is regularly ventilated. Owners of sewing devices should remember that proper care of them contributes to comfort at work and long term use. In addition to cleaning and lubricating the sewing machine, one should not forget about the regular change of needles, the correct threading of threads, as well as accuracy in work.

You can watch the video on how to clean and lubricate the sewing machine.