Manual sewing machine is a real classic, with which you can still learn the basics of creating the first stitches. Modern manufacturers also do not forget about the simplest solutions, offering the best options for minor household repairs of clothes - ordinary mechanical sewing machines with manual transmission. Consider how relevant today are models without an electric drive and computer control.

But before you thread the thread and start sewing on a classic manual machine, It is worth studying the basics of its structure and principles of work. Fully mechanical technique requires constant care, adjustment and adjustment. You cannot create complex lines with it. But you can get basic sewing skills and good experience in servicing these kinds of mechanisms, which will certainly come in handy when using more complex equipment.

Device

The manual sewing machine has simple drive mechanism, able to create straight, straight lines or sew in a zigzag pattern. In its configuration there is all the necessary technical equipment for work. Some modern models may work. and on batteries - in this case, the start and stop of the needle stroke is controlled using a special button. These devices are universal - they can also be used in manual mode, as on conventional mechanical options, that is, by rotating the shaft with a special handle.

This category of equipment lacks pedals and foot control systems.

The device of any sewing machine with a manual drive necessarily includes:

- platform or base;

- line parameter adjuster;

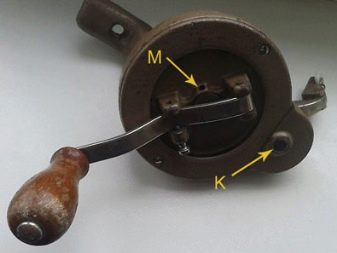

- manual drive mechanism;

- winding unit;

- flywheel;

- sleeve part of the body;

- a needle plate on the bed;

- rack bottom conveyor;

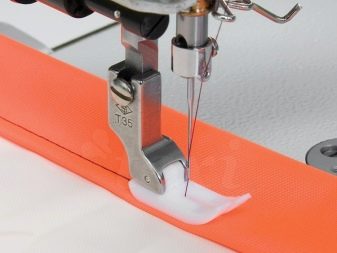

- presser foot;

- shuttle;

- needle bar;

- the front panel on which the upper thread broaching device is mounted.

Classic hand-held machines have the ability to translate the flywheel to working or idle. Depending on the tasks assigned to the seamstress, you can activate the desired option using a special disconnecting screw, for example, wind the thread on the bobbin or start sewing.

Modern manual sewing machines have a fundamentally different design than the old models, and look more like a stationery device - a stapler. When the edges are compressed, the needle passes with the thread inserted into it over the edge of the product, resulting in a stitch.

Principle of operation

Manual sewing machines have a fairly simple principle of operation. The main part of the design in it, in fact, is the shuttle mechanism, which is activated by the complex interaction of other elements. In general, the operation scheme of such a technique is as follows.

- Bobbin - compact reel for winding the bobbin thread. She is inserted into the shuttle. On its body is a "nose" - an element that prevents accidental loss of the spool. The tension of the lower thread is adjusted using the shuttle screw - when tightened, it rises, when loosened it decreases.

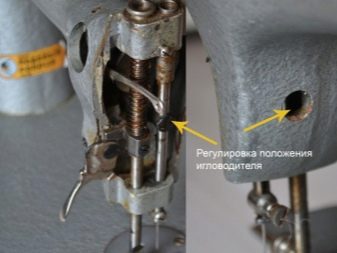

- Shuttle after installation in place it is in close contact with the connecting rod mechanism, which, in turn, is driven by the shaft of the machine. When the flywheel rotates, the needle moves - it plunges into the work platform. At a distance of 5 mm to it is a grip - an element of the shuttle. If the gap is maintained correctly, the machine sews normally. When it is distorted, a failure in the bonding of the fabric begins, skipping stitches.

- Plunging into the working platform, the needle goes into the shuttle, which hooks the bobbin thread with the upper thread and weaves them. The work of absolutely all sewing equipment is based on this repeated movement.

- Simultaneously with the movement of the needle the material pulling device is also driven. The main shaft, passing through the center, activates the flywheel, shifting 2 rods, which activate the work of the lower conveyor.

- Upper thread tension is carried out using a system of elements into which it is sequentially refueled. The freedom of movement of the thread stretched between the discs is regulated by a special screw. In addition, the special eye in which it is threaded moves with the movement of the needle, providing a constant and uniform tension.

With a combination of all these factors, processes occur in the sewing machine body and on its outer surface that automate needlework.

For more information on manual sewing machine, see the next video.

Advantages and disadvantages

Among the obvious advantages of manual sewing machines, several points can be noted.

- Reliability. The mechanical construction is extremely rare to fail with careful handling.

- Durability. Many manual machines that have crossed the half-century mark are still “in operation”.

- Ability to work without electricity. Complete independence from the current source is an important point that distinguishes classic cars from other instances.

- Enhanced functionality when replacing the presser foot. You can sew a button or insert a zipper, learn quilting and embroidery.

- Minimum purchase and maintenance costs. In the secondary market, you can purchase sewing equipment at a very low price.

These are the disadvantages of manual sewing equipment should be attributed massive devices, lack of a wide range of functions. For sewing leather you need to take additional measures or put a Teflon foot, which can not always be adapted to the design of old machines.In addition, new models of manual sewing equipment require certain skill when using, and they are not designed for long continuous operation.

Instruction for use

In order to use a manual sewing machine without problems and for a long time, each work needs to be started by checking the health of the units. If there was a long downtime, it is recommended to renew the lubrication of the main working elements that need this operation. Lubrication is made with specially designed oil for sewing machines.

If rust or severe contamination is detected, the mechanism will have to be partially disassembled to clean the lubricated parts from dirt and dust, and only then cover with lubricant. After such an operation, the technique will need to stand for at least 24 hours, and then perform a test run of the parts on a piece of unnecessary fabric.

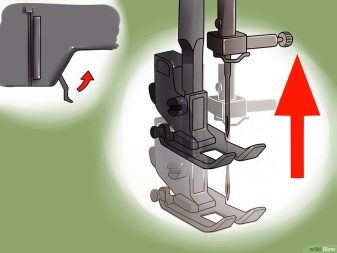

To stitch the fabric, you must first set the needle correctly. To do this, you need to get a set in advance, which will present options for thin fabrics, leather, jeans and other materials. The thickness or number of the needle depends on the type of matter - the smaller the number, the thinner the fabric. To fill the needle in place, you need to raise its holder to the very top and select the correct positioning - with a long groove towards the base of the sleeve.

The needle is inserted all the way, fixed with a screw so that there is no free play.

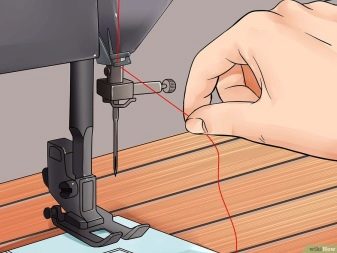

And now let's see how to put a thread into a manual machine. First, work is carried out with the upper part of the machine, the procedure will be as follows:

- the coil is mounted on a special pin;

- its end is sent to a small mount located behind the device;

- the thread extends to the tension regulator, passes through it, and also through the loop on the front panel;

- then the thread is displayed on the needle and threaded through its eye from the outside towards the base of the sleeve.

To thread the bobbin thread, the bobbin is placed in the shuttle so that so that the thread rotates clockwise when tensioned. The thickness of the threads in the hook and the upper guide should be the same. By extending its tip and passing it along the fixtures of the lock, you can put the device in place inside the case so that about 15 cm of thread remains on the outside. Next, scroll the handwheel so that the needle sinks into the bed and passes through the shuttle. The hooked bobbin thread will be raised, it will remain straightened and positioned across the working metal pad.

General rules for the operation of manual sewing machines are as follows:

- Do not use pins to cleave tissue;

- to exclude contact of fingers with a needle during sewing;

- be sure to close the shuttle compartment lid before operation;

- Do not pull matter to advance it;

- the rotation of the flywheel is made only towards you;

- all non-working hours, the foot should be raised;

- Do not rotate the flywheel while there is no blade on the platform.

Following these recommendations, you can avoid many unpleasant breakdowns and injuries associated with the operation of the mechanism.

Model Overview

Soviet industry was not very original in the design of sewing equipment. The most famous hand-held machine is PMZ (or Podolsk) - almost completely repeats the design of Singer equipment, under the license of which equipment was manufactured in those years, even in China. For the USSR, the appearance of the creation of Podolsk masters was very helpful. Young Soviet industry needed the mechanization of seamstress labor.

It is worth noting that the PMZ plant was founded in 1902 as a representative office of the company Singer and by 1913, output reached 2,000 units. The enterprise received its modern name after nationalization, in the 30s of the XX century. Since that time, the original parts of the German brand began to be replaced by domestic ones.

The most popular was the Podolsk 2M model with a manual drive and high quality parts.

Chinese sewing machine Buterfly - The “twin” of PMZ products is also produced under license from Singer. The model is capable of performing only 1 type of lines in a straight line. Its difference is not too great, but still there is: the end of the cap of the spool is turned not to the left, but to the right. If you have experience in sewing at Podolsk, it will not be difficult to master Buterfly.

Seagull 2 - One of the first production cars similar to modern models. It was produced with foot and manual drive, knew how to make straight seams and zigzag, but had no reverse.

Minerva - A popular manual machine manufactured in Czechoslovakia. It focuses only on the creation of a straight stitch, has an adjustment along the length of the stitches, and in its design is almost similar to standard Singer models.

In addition, among the manual models can be noted German Kohler and Csepel 30 Hungarian production.

Modern hand-held cars

Models of manual sewing machines from China are popular today no less than their Soviet counterparts. Such a portable model can work on batteries or without them. This device format provides sewing capabilities without shuttle and spool. The device is equipped with only 1 thread, a stitch adjuster, it easily copes with the formation of stitches in a straight line.

We list the best cars in this category.

- Zimber This is a multifunctional machine that can perform up to 8 different tasks. It is used by craftswomen working in the patchwork style, as well as home needlewomen.

- Jaguar Mini 276. A popular and inexpensive sewing machine with lots of features available. It can handle 8 operations, performs loop processing in the semiautomatic mode, overcasts the edges, and can sew elastic fabrics.

- Bradex TD 0351. A good solution for fixing a home wardrobe, sewing curtains. This is a machine with limited functionality, a budget purchase for a beginner seamstress.

A Chinese sewing machine of this level cannot be considered as a full-fledged alternative to the real manual technique, but it is indispensable as a means for quick home repair.

Possible malfunctions and their elimination

Correction and elimination of malfunctions encountered when working with manual sewing machines is quite possible even for a not too experienced master. It is worth considering the most common problems in more detail.

- The handle is spinning badly. Without long operation or proper maintenance of the mechanism, the grease thickens, dries, the working shaft gradually rusts, and its rotation becomes difficult. To eliminate the problem, cleaning the mechanism from old oil, dust and dirt will help by filling in kerosene. The machine should be soaked for at least 24 hours. Then the mechanism and parts are thoroughly cleaned, followed by lubrication of all nodes. If necessary, repeat the procedure, achieving easy and soft rotation of the shaft.

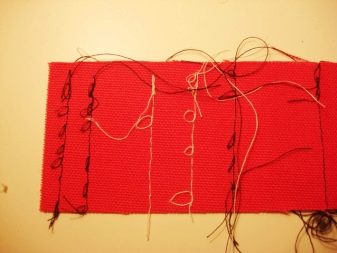

- The needle skips the lines, does not sew. It is necessary to check the correct positioning. An incorrectly inserted needle can cause serious problems with other structural elements.

- Excessive tension on the bobbin thread. You need to loosen the screw on the hook. If it does not help, you will have to make a full cleaning of the mechanism, removing adhering dust, tows and dirt from metal parts. The brush removes all extraneous dirt from the grooves and teeth inside the housing. You can use a hard toothbrush and a mini vacuum cleaner for cleaning.

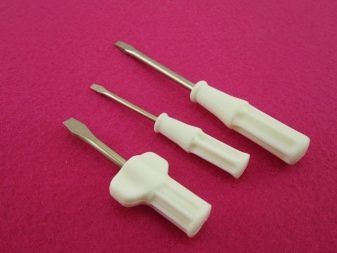

- Backlash of parts. To adjust, you need a screwdriver to tighten all the elements. If the fasteners are presented in the form of self-tightening nuts, the screw must be held during rotation.

Following these tips, you can easily deal with breakdowns of equipment, and provide it with a good job for a long time.

See how to use a manual sewing machine in the next video.