Without threading, no sewing machine can start work. A thread is that component without which it is impossible to sew the same or different types of matter: in this case, one would have to resort to other methods and technologies that are different from sewing.

Preparatory stage

Make sure that there are no threads in the machine that you do not need right now. If they are present - they are easy to pull out.

Check that the upper thread tensioner is standing. It must be serviceable and workable, all parts must be in place. If there are fibers from the old threads, clean the tensioner with a brush. Pull out and inspect the shuttle, bobbin with cap for chipping.

Remember when you last lubricated the mechanism. If it was long enough, for example, more than six months have passed - disassemble the machine, check the condition of the mechanisms.

Clean them if necessary. Use industrial or motor oil to lubricate moving parts. Assemble the machine, plug it into the network and drive it idle for a minute.

Make sure that during the test run all the mechanisms work smoothly, clearly. There should be no slowdownwhen you are not waiting for it, as well as the progress of the mechanisms with noticeable effort.

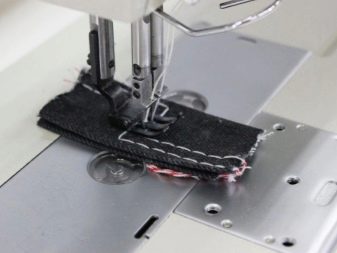

Set the shuttle in place, insert the needle corresponding to the thickness of the upper thread with which you are going to sew fabrics of a specific thickness and texture. For household sewing machines, needles are used with a bulb cut along one side.

The nuances of refueling, depending on the type of machine

Properly threading the sewing thread is easy.In any sewing machine, there are only 2 stages of threading: broaching the upper thread (into the needle) and the lower thread (through the shuttle mechanism).

A machine with two or more needles - the lot of true professionalswhich, according to the project of sewing an element of clothing or an accessory, need as many seams at the same time. How many needles, so many refueling stages: each needle sews its own thread independent of the “neighbor”. Multi-needle and multi-reel machines are, in fact, a mini sewing conveyor that speeds up sewing as many times as needles are used on this device.

The simplest option is a double-needle machine: the two upper threads are used here. They hang on the same side. Each needle uses its own “descent” on the needle bar. The coils on the machine are located at the top on both sides of the working axis of the needle bar.

But with a double (triple or more) needle, the needle threader is not recommended - you can damage them adjacent to the needle being refueled at the moment.

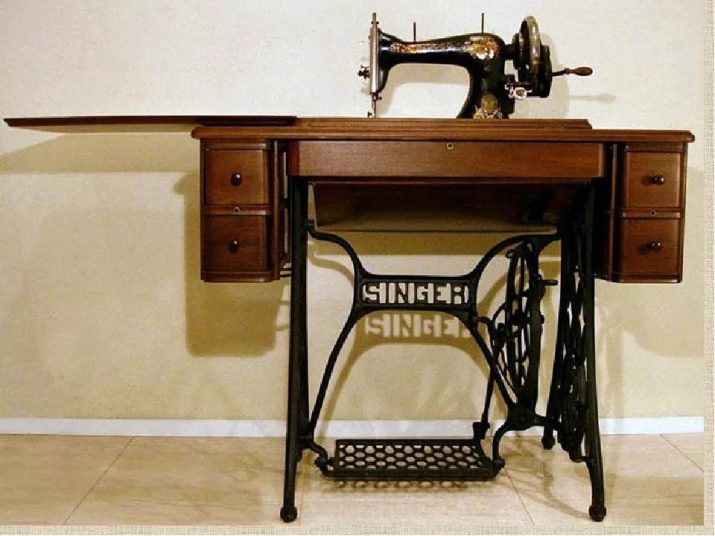

In single-needle household Soviet cars, for example, the old generation Singer, Podolsk, Seagull, PMZ, the upper and lower threading approximately matches the general pattern. There is no need to give any special advice here. The sequence of actions can be any - it doesn’t matter if you knit the upper or lower thread first, the result will be one.

But before proceeding with threading, it is necessary to introduce the separation of machines according to the type of drive: manual, foot and electric (electromechanical device).

Manual

Previously, the type of machine was considered to be a manual machine, in which instead of an electric motor and a drive shaft, a special lever was combined with a gear gear, which, in contact with the main one, spun it, forcing other mechanisms to work from the kinetic energy transmitted by this "twist".

But today, in online stores they sell the simplest single-thread sewing stapler - a portable device with one reel, which, in addition to the needle holder, has the simplest thread guide, tensioner (like what is in Soviet cars), the simplest shuttle. The bobbin mechanism - and with it the lower thread - is completely absent, that is, the “stapler” stitcher is “one-way”. The pulling of the upper (single) thread is carried out almost in a matter of seconds. If the thread is chosen exactly according to the thickness and stiffness of the fabric, you can start sewing, but you will have to move the fabric manually on each stitch.

There is also a motorized (electric) version of the sewing stapler - a single-thread portable sewing machine. It is equipped with the simplest collector motor, operating from a direct current with a voltage of several volts. A tissue mover having tines moves the fabric automatically. However, on such a machine there are no protective guides that prevent tissue from going sideways and the appearance of a curved seam.

Sewing is started with the button on top, but enterprising users remove it and connect such a machine through a switch pressed by the foot. The fact is that hands should hold and guide the stitched fabrics on both sides - otherwise the seam, again, will come out crooked.

So, to thread the upper thread in a classic sewing machine (and not in the sewing stapler that we just talked about), do the following.

- Put the spool on the pin in the upper part of the body and unwind from it half a meter of thread (or more).

- Pass the needle through the upper thread guide and the tensioner, which has a spring-loaded screw (or nut on the bolt). The thread is clamped between the brackets, convex side to each other.

- Pass the thread into the eye of the tensioner lever, and then into the “trigger” on the needle bar.

- Pass the thread into the eye of the needle already inserted in the holder, pass it through the cut of the foot - and take it to the side (away from you).

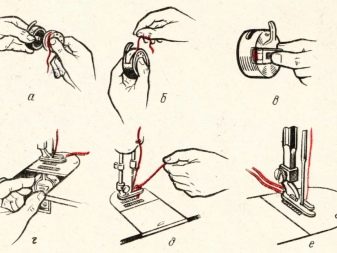

Follow these steps to skip the bobbin thread.

- Open the lower compartment by sliding the protective (closing) plate to the side and pull out the cap with the bobbin.

- Insert the bobbin onto the axis of the winder and lock it there.

- Switch the machine to bobbin winding mode. At the same time, the needle bar mechanism and the shuttle will be immobilized - the force from the “twist” will be transferred directly to the “winder”, and not to the main mechanisms that carry out sewing. Switching between the sewing and winding modes of the bobbin is carried out using a special lever that takes the intermediate shaft of the main mechanism and transfers it to the transfer gears of the winder.

- Put the spool of thread on the lower pin, located immediately below the “coiler”.

- Unwind a little thread from this spool and pass its end to the bobbin.

- Lower the pinch roller holding the bobbin to the axis and start turning the twist lever. With your other hand, point the thread at the bobbin so that it does not wrap around and does not become entangled.

- Unwind 10-20 cm of thread from the bobbin. Insert the filled bobbin into the cap and the cap into the shuttle mechanism. It should snap into the holder with a click.

- Pass the end of the thread through the hook tensioner.

- Close the protective plate and pull the end of the thread from the bobbin under the presser foot - into the same cut. Take the thread in the same direction as the top.

Now you can prepare the fabrics for stitching.

Do not forget to put the switch lever (next to the bobbin winder) back to the “Sewing” position.

Foot

Leg machines of old generations in terms of threading are generally no different from manual ones. The mechanisms and devices included in their composition are placed on the body and under it in exactly the same way. The only difference is that the sewing operator does not rotate the hand crank, but rhythmically shakes both legs with a long transverse pedal wound to an external gear with wooden or plastic guides. A large gear ratio on the drive wheel transmits torque to the drive shaft of the machine through an external drive belt.

Remotely, such a device resembles an elevator car in the entrance of an apartment building, working the other way around: the motor lifts the elevator car to the desired floor through the gear wheel, and the cab, lowering back down, rotates the engine through the same gear wheel. Old foot machines, like manual ones, are completely autonomous - they do not need electricity.

To thread a foot in a foot sewing machine, use the manual instructions above. Currently, foot sewing machines are supplanted by simple manual units and much more advanced electric ones.

Electric

Refueling an old (Soviet) electric sewing machine, for example, Podolsk or Singer, is no different from its manual predecessors. Only the "Seagull" is distinguished by the location of the tensioner, guides and the upper thread tension lever - they are located in front, on the user's side, and not on the side. But the threading of the upper thread at "Seagulls" is about the same.

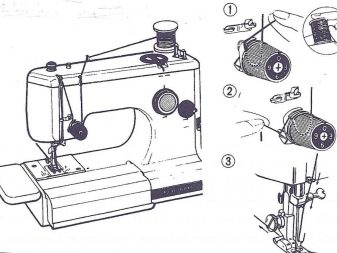

Modern sewing machines - for example, manufactured by Brother, - the procedure for upper and lower threads is as follows.

- Put the reel on its pin - on top of the typewriter body.

- Pull a little thread from the spool.

- Lock the end of the thread on the bobbin. Modern bobbins contain two holes opposite each other - thread the thread into both at once. Wrap a few turns so that the thread does not slip off the bobbin.

- Attach the bobbin to the rewinder bar - it is not far from the main coil core.

- Move the lock to the leftso that the bobbin does not pop out when winding the thread.

- Run the bobbin winder using the foot pedal.

- Winding up a full bobbin take it out by sliding the latch back.

- Remove the coilwith which you wound the thread on the bobbin, and set the desired one instead. The thread should be slightly thicker than the one used on the bobbin.

- Thread the thread from the spool behind the thread guide slot. It is located at the top of the device, but much further than the bobbin winder.

- Insert the thread into the U-shaped channel on the machine body. Pass it through the disc-shaped tensioner.

- Expand the thread and wind it along the continuation of the channel up. Pull it through the attractor - it has an outlet. Pass the thread through it.

- Lower the thread down to the needle - and push its end into the needle itself. Before that, pass it through the last guide.

- Pass the thread through the slot on the foot. Take the thread to the side.

- Open the hook cover. It is placed next to the needle. If there is another protective cover under the main (optional) - remove it as well.

- Sew about 10 cm of thread from the bobbin you just wound. Insert the bobbin into its seat. Pull the thread slightly from the bobbin to make sure that it spins effortlessly.

- Close both covers (if there really are two, not one).

- Pull the end of the thread up. Roll it into a loop. Pass the upper thread through this loop. Twist the handwheel so that the upper thread pulls the lower thread. This is necessary so that the seam when stitching fabrics is obtained as it should eventually be.

The difference between modern and old sewing machines is that the thread goes a longer way, hiding under the edge of the device’s body.

Possible mistakes

If the machine does not sew properly, the thread breaks or sags, make sure that you have not made any of the following mistakes.

- The thickness of the needle and the size of the hole (eye) does not correspond to the stiffness and thickness of the stitched layers of matter.

- You missed the tensioner, thread guides or violated the sequence of its broaching, refueling.

- You are trying to sew without upper or lower thread.

- The machine is de-energized. You have not connected it to the network.

- You have wound too much thread around the bobbin, making the first one difficult to rotate.

- The upper thread is equal in thickness (or less) than the lower thread.

- You use too coarse threads - for example, purely hb, and not synthetics (or semi-synthetics).

- You have chosen the wrong type of seam, which is unacceptable at this stage for the fabric that is now stitched.

- The upper thread tensioner is too loose or too tight.

- The bobbin and its cap are noticeably broken over the years or with careless storage. Chips, nicks appeared on the bobbin.

- The machine was not lubricated on time. She spins with noticeable effort, overcoming it. From this, the speed dropped significantly. The machine scribbles in jerks, constantly changing the number of stitches per second (and minute), that is, its speed, speed is in question.

- Clogged, worn thread tensioner.

- Spools of thread lay for several years and lost their characteristics: strength, elasticity, smoothness.

Other signs, such as sagging stitches in stitches, may indicate errors. The reason is that the upper and lower thread tensioners are not carefully adjusted. Ideally, it should be the same.

Conclusion

Threading the thread from above and below in any machine - whether it be a device with a manual, foot or electric drive - will not be difficult. After threading, check their tension. If everything is done correctly, the machine in all cases will work without problems.

See below for how to thread the thread into the sewing machine.