No matter how perfect, “advanced” and reliable the sewing machine is, an experienced master checks its settings before each session. This is vital for the unit to run smoothly for a number of years before it is repaired after a breakdown or replaced with another.

What parameters can be adjusted?

The need to fine-tune the operation of the sewing machine is a consequence of the not quite correct selection of threads of the appropriate thickness for a particular material. No less important is a needle suitable for fabric and thread. For example, thick and coarse material requires a larger needle number and a smaller one for thread. Then set the following settings.

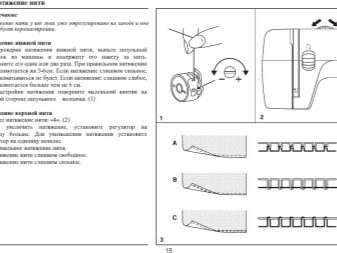

- The length (pitch) of the stitch is 2 mm. Thin matter requires more frequent stitches, thick - on the contrary, but not more than 4 mm. The thickness of the fabric (its total value for several stitched layers) on electronic sewing machines using the controller is set on a scale. The upper position of the knob means that the pulling rollers that advance the fabric will not spin. The lower the arrow of the control, the longer the stitch the machine will produce.

- Reverse (fabric is fed backwards) - the movement of matter towards the tailor. You can enable this mode using the adjustment (multi-position) lever, setting the desired value. The length of the stitch remains the same - there is no need to pull out the matter and stop the process.

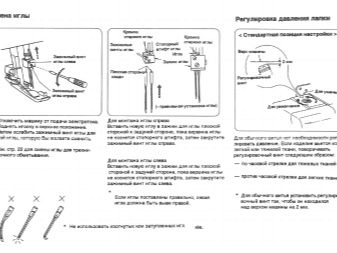

- The force exerted by the foot to clamp the fabric. Working with lighter matter, for example, when sewing silk products, needs only a slight decrease in the clamping force from the side of the foot.Thickened and coarse fabric needs to increase the pressure so that the fabric does not accidentally move, which would lead to a curved seam. Adjustment of the clamping force acting on the fabric is carried out by a screw on the handle of which the markings are applied.

- The thread tension should be such that the lower and upper threads curl in the middle of the stitched layers of fabric. On both sides, the seam looks the same. It is necessary to adjust the screw on the tensioner itself.

Basic Rules

Even a novice can independently adjust the parameters of the sewing machine. You must use the product instruction manual, but when something is not completely clear, contact a more experienced tailor.

- Adjust the spring, with which the thread moves up to the needle. Find its position at which the unwinding of the thread is carried out when it is fixed with a bobbin.

- Get the right thread pulling force - it is carried out by means of the mechanics of the shuttle adjusting screw and in front on the machine itself.

- Test the device after tuning. You will need an unnecessary flap. After completing the test stitches on the newly tuned machine, check for hanging stitches. If they are, the upper thread tensioner is too tight, loosen it. Repeat the test stitching - the seam with the correct tensioner setting will come out smooth, uniform, not overtightened. At the same time, in the middle there are nodules that are not felt during a detailed examination.

- The correct pressure value on the presser foot side is selected by turning a separate screw. In most models of electromechanical and electronic sewing machines, it is present in the access area and rotates without much effort on the part of the user. This is necessary for an accurate and quick - within seconds - adjustment. Do not overtighten or loosen this screw excessively. In the first case, the fabric can tear, in the second - the seam will come out folded, because the presser foot does not press the layers of matter properly.

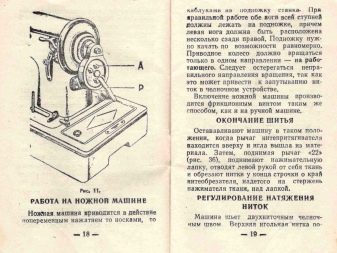

- Make sure the drive is up and running.n Get the optimal speed of its drive shaft (rpm sufficient for quick and comfortable operation). This parameter is set using the knob on the foot pedal. There are times when the machine starts abruptly even with a slight pressure on the pedal. The pedal itself must also be cleaned regularly.

- Finally, check the correct operation of the needle holder. The needle should not be blunt, otherwise it will tear the material with each piercing in a new place before applying a new stitch.

These rules are also suitable for tincture of an old manual sewing machine.

Step-by-step process description

Depending on the model and year of manufacture, the sewing machine setting may vary.

After downtime

The step-by-step guide in case of idle sewing machine is as follows.

- Disassemble the device and check which parts are oxidized. Clean them from rust and grease. If any part has collapsed (for example, the machine has stood for a long time in high humidity) - try to find a replacement for it. If the parts have been discontinued, perhaps contact a turner or milling machine operator to make them (show the specialist a drawing and what remains of the old part). The action makes sense when the rarity is valuable in itself, and it is worth trying to restore it.

- Raise the foot and idle the machine without threadsso that the oil spreads over the rubbing surfaces.

- Change the needle (if it was originally) or immediately put a new one.

- Thread the desired thickness and strength, drive the machine on an unnecessary piece of matter.

If the machine sews well, proceed to full-fledged sewing.

How to configure the machine PMZ?

PMZ is able to flash fabric of any thickness and density. It’s not a problem with it to stitch together several layers of different elasticity and thickness.Although this machine has been around for almost a century, it has been used by experienced seamstresses to this day. This is one of the few devices created literally for centuries. To configure the Podolsk model, do the following.

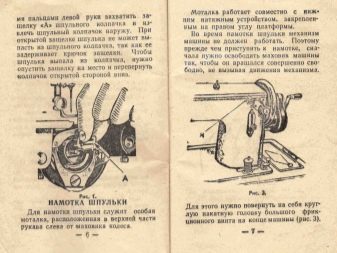

- Wrap the required amount of thread on the bobbin. The winder is located at the rear, next to the flywheel, with which the thread tensioner also interacts. Install the bobbin on the rewinder, and the spool of thread on the shaft at the top of the housing. Pass the thread under the tensioner washer and secure its end to the installed bobbin. Pull the winder frame down until the pulley rim and the twist ring touch. Turn the handwheel to wind the thread on the bobbin. Operate the free edge of the thread so that the bobbin is filled evenly.

- To install the bobbin with thread, fix it in the cap so that the beveled slot remains on top. Through the latter, the thread unwinding during work comes out. Further, the same thread bypasses the clamping spring and exits through the end slot. Lock the cap with the bobbin, pull the end of the thread out and close the shuttle compartment.

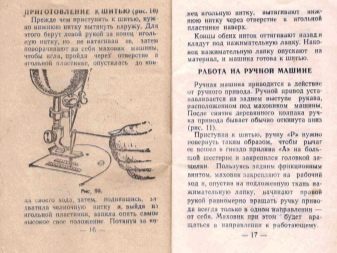

- When threading the needle, be sure to lock the flywheel with the locking screw, turning it to the side of the worker sitting at the machine. Before this, move the needle moving mechanism with the drive handle to the leftmost position. In this case, the cut of the needle bulb should be turned to the left. The pulling lever is retracted to its highest position, then the upper thread is threaded into its eye. The flywheel scrolls towards the seamstress. Pulling the thread through the tensioner and thread guide, thread it into the needle.

- Pull the bobbin thread outward turning the twist.

If everything is done correctly, then when immersed, the needle grabs the bobbin thread. Then it rises up, and both threads are passed through the stitched layers of matter.

Seagull Setting

In the Chaika typewriter, the tuning algorithm is similar to Podolsky, but it differs somewhat. After disassembling, cleaning and lubricating, assembling the machine, do the following.

- Install the thread and needle. To set the top of the thread, turn the handwheel until the needle bar and thread tensioner are at their highest positions. Insert the reel into the reel seat until it stops. Turn the coil with a flat cut towards the foot, fix it with the screw so that it does not fly off during operation. Pass the thread through the guide, clamping mechanism, tensioner lever, needle holder loop and needle hole.

- Wind the bobbin thread onto the bobbin, filling it to the limit. Insert the bobbin into the cap and pass its end out.

- Turn the twist pull both threads and put them under the sewing foot.

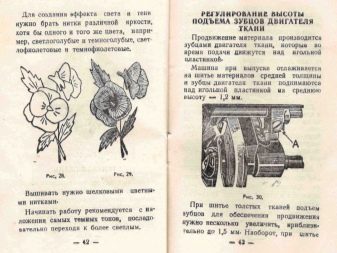

The Chaika machine has a disc with different working positions. If the matter is thick and rough, the teeth of the disc bulge outward. In the case of thin tissues, they hide. After completing the adjustment, lower the presser foot with the needle, turn the twist to you. You can start the sewing process by substituting the fabrics to be sewn into the stapler.

Setting up modern models

Use the instructions that came with the kit. Most new models function the same, but step-by-step instructions may vary. Do the following:

- adjust the optimal position of the working parts using special rollers for adjustment;

- adjust the position of the bobbin so that its cap protects the thread from excessive unwinding;

- normally, the thread moves in a strict sequence: first through metal holes, then through the tensioner, thread pull lever, drain hole on the needle holder and through the end of the needle.

Parts with which the thread is properly tensioned are placed within the shuttle screw, as well as on its end side (upper and lower thread).

After setting, make a test seam on an unnecessary flap of matter. An indicator of the correct seam is small nodules in the middle of each stitch, with no hanging loops.

The correct position of the foot is adjusted using the corresponding spring. If the foot is not debugged, the fabric will tear or the seam will easily open at the slightest tension. Be guided by the thickness and stiffness of the material, the parts of which you want to sew.

Also set the required number of revolutions per minute. The motor speed controller is placed on the foot pedal. If the engine speed controller is unstable, disassemble and clean its contacts. With complete wear of its live parts, a complete replacement of this component is required.

If there is a tooth adjuster on this machine, insert a needle of a suitable height, which will affect the length of the stitch. A thin thread should form a stitch no more than 2 mm long. For thick threads, the stitch is set to a length of 3-4 mm.

When is adjustment required?

The sewing machine setting is needed in the following cases:

- before starting sewing another product for which matter of a different thickness and texture is used, as well as a thread of a different denomination;

- after prolonged downtime - moreover, repair, cleaning and lubrication of parts and mechanisms may be required;

- in the process of planned prevention.

Ignoring reconfiguration of the sewing machine can lead to damage to at least the needle, to tangled threads and damage to the material. The latter is especially undesirable when the matter is “fine”, ceremonial, and you don’t have an additional amount at hand.

Even sewing machines of the lower price range - from several thousand rubles - are able to work ten years without any problems. And it doesn’t matter if you use the machine once every few months or if it works intensively and productively for several hours a day - fine-tuning, checking its work is important so that this work does not stand.

Setting the old sewing machine "Podolsk" is presented below.