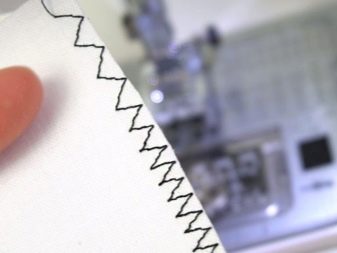

Overlock is a device from the category of sewing equipment that allows you to evenly trim and process the edge of a fabric product. Only a skilled craftsman can perform the difficult settings and repair of this device, but it is quite possible for an ordinary user to choose and debug the thread tension before starting work.

Basic Rules

The principle of regulation does not depend on whether you have an overlock in Taiwan, Japanese or Chinese, since the thread tension regulators are placed on the outside of the machine body. As a rule, there are 4 of them, according to the number of threads involved in the process of washing. All regulators have a scale of degree of tension from 0 to 9.

For each type of fabric before starting work, you need to configure an overlock.

The values of the regulators are set depending on the thickness of the fabric and the type of thread used. In most cases, overcasting can be done at a set tension value under the number “4”.

But do not immediately start processing the product itself. Pre-check the quality of the seam on the flap of the fabric and, if the process went well, you can start work.

The degree of tension of the thread is regulated as follows:

- from 2 to 3 - low tension;

- from 3 to 5 - average tension force;

- 5 to 7 - strong tension.

An important condition for high-quality lining of the material is the thickness of the thread, and it is important that all 4 threads are of the same type and thickness. Another condition for obtaining an even stitching stitch will be the correct selection of the needle thickness number corresponding to the density of the treated fabric. Typically, for each overlock in the operating instructions, the manufacturer indicates the brand of needles and their recommended numbers.

If the needle is selected to an inappropriate size and thickness, this can lead to a malfunction of the basting process, and in some cases even damage to the machine.

Thread tension

Each tension regulator performs its function, on the overlock they are painted in a certain color. Their function is as follows:

- first regulator - is responsible for the tension of the thread of the left needle of the machine;

- second regulator - is responsible for the tension of the thread of the right needle;

- third regulator - pulls the thread of the upper looper;

- fourth regulator - pulls the thread of the lower looper.

When setting up, we use a piece of takni as a prototype and carefully inspects the quality of the line. Inspection and the necessary adjustment are done in the following sequence.

- Check the operation of the left needle. If wrinkling is visible on the fabric, it means that the pulling force of the thread is too great. Therefore, we reduce the indicator of the regulator by one division and again check on the fabric sample how the line will look. We do the reduction of tension until the wrinkles on the treated section disappear.

- Check the evenness of the line. The left needle is also responsible for this. If we see a "ladder" of threads, it means that the tension needs to be slightly increased.

- As soon as you find the right indicator for the left needle, in which you get an even line without wrinkling the fabric and loosening the threads, we set the same for the right overlock needle.

- We evaluate the work of loopers. The line on the fabric should be even, the pattern between the stitches is uniform. If you see loops of threads beyond the edge of the cut of the fabric being processed, it means that the tension of the loops is too weak - it needs to be increased. The adjustment is carried out until the threads for which the loopers are responsible, lie flat.

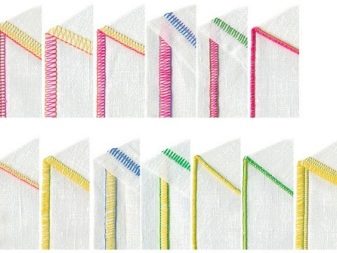

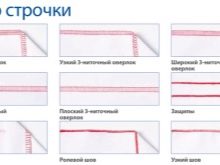

When processing the product, it is important to choose the type of stitch that matches the thickness of the fabric. Most modern overcasting machines can carry out at least 5 types of stitches.

- 4-thread stitching. In the process, all 4 threads and 2 needles are used. Such a stitch provides a durable seam and can be applied to knitwear and any dense textile.

- A sewing stitch of 3 threads with a seam width of 5 mm. It is carried out by the left needle and 3 threads. Suitable for medium density fabrics.

- A sewing stitch of 3 threads with a seam width of 2.8 mm. It is carried out by the right needle and 3 threads. It is applied on a thin fabric.

- Narrow stitching 2 mm wide. Used on chiffon and other delicate fabrics.

- Binder stitch 2 mm wide. Used as a decorative for delicate fabrics.

When processing thin fabrics, it is important not only to adjust the performance of the thread tension regulators, but also the presser foot of the machine. If the presser foot pressure is too strong, no adjustments will help, and the fabric will wrinkle during processing until the cause is eliminated.

Stitch size

In order to get an even line when processing the product, among other settings, it is important to choose the right stitch size. For this, there is a special regulator with a scale of divisions on the machine body. The choice of indicator regulator depends on the density of the tissue. The thinner the fabric to be sewn, the smaller the size of the stitch. When choosing a stitch length, be sure to consider the thickness of the thread.

When setting up an overlock, the following information will help you orient yourself:

- thin fabric (georgette, cambric, kiseya) - stitch 2-3 mm, thread No. 80-90;

- medium thickness material (fine cloth, gabardine, serge) - stitch 2.5-3.5 mm, thread No. 60-80;

- thick fabrics (tweed, jeans, knitwear) - stitch 3-4 mm, thread No. 50-60.

In some cases, during operation, you will see that the stitch has skipped stitches. The following actions will help you adjust this process:

- check the condition of the needle - whether she bent, whether correctly installed;

- take out the needle and check its number - if it does not match the type of your overlock, replace;

- Check if your car is properly refueledwhether one of the mounts is missing;

- make sure that the threads are not wound on the stitch adjustment pin;

- estimate the pressure of the presser foot.

After checking all the indicators, make a prototype and, making sure that the overcasting machine is working properly, proceed with processing the product.

Recommendations

For normal and long-term service of your overlock, it is necessary to regularly carry out its maintenance. This procedure consists in the following.

- Cleaning mechanism. This simple manipulation is performed every time after the completion of work. It is necessary to remove dust, scraps of fabric, threads. This can be done using a hard brush with stitching movements.

- Overlock lubrication. To ensure smooth and silent operation of the moving parts of the mechanism, the machine must be periodically lubricated with special oil. Lubrication is performed only after thorough thorough cleaning.

If serious malfunctions are detected, the overlock should be repaired at service centers for maintenance of household appliances, and when replacing components or parts, it is important to use only original spare parts from trusted suppliers.

For more details on overlock settings, see the video presented.