Sewing is one of the most common hobbies of women. With a simple sewing machine and a small amount of skills, each housewife can make unique designer outfits. For to sew high-quality and durable clothes, it’s not enough just to sew seams, you need to process their edges with an overlock. Manufacturers produce a wide range of this sewing equipment, which can be either as a separate device or integrated into the sewing machine.

Despite the presence of new overlocks, many seamstresses will continue to use old proven equipment that is easy to use, unpretentious and reliable. Overlock of class 51 refers to this technique.

Characteristics

Overlock 51st class is a professional sewing equipment that can be used both for personal needs and in small sewing workshops. For many years, this device remains in demand in the processing of products. The primitive design makes it impossible to cover modern types of fabrics, but the equipment is indispensable during sewing products from coarse and durable types. This sewing device is more reliable and durable than the Chinese counterpart. For the quality performance of work, manufacturers have provided the following functions in this device:

- thread tension adjustment;

- change in pressure of the presser foot on the fabric;

- adjustment of the distance between the needle punctures.

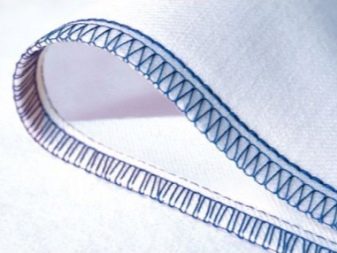

Functional tasks of an overlock of 51 classes and 51-A classes - processing of the edges of knitted, linen and dress-making products using 2 and 3 thread chain seams. The stitch length is in the range from 0.3 cm to 0.6 cm. The maximum thickness of the processed material is 3 mm. The optimal needle mark is 0029, number 60-70.

This appliance is equipped with a needle mechanism and two loopers. If you replace the right looper with an extender, you can use only two threads. For overcasting jerseys, it is better to give preference to overlock 51-A class, which has a differentiated mechanism for moving the web. Due to the greater movement of the front scarf, the effect of stretching the material is achieved, which allows to make the seams more elastic and stretching.

A distinctive feature is the presence of centralized wick lubrication of moving parts, which are located under the platform of the sewing equipment. For uninterrupted lubrication of all elements, it is necessary to regularly check the presence of a lubricating solution in the crankcase. To lubricate all other elements, use a container with a long spout. In case of constant use of the device, experts recommend holding this event at least 1 time in 30 days. For the smooth operation of the device, it is necessary to lubricate all the contacting parts, and in the process, they must be constantly turned.

For the convenience of the work, the masters recommend using a graduated cylinder in the form of a cone for injection instead of a lubricant tank.

Advantages and disadvantages

Like any household sewing device, an overlock of class 51 has both positive and negative sides.

Advantages:

- affordable price range;

- reliability;

- simplicity of operation;

- universal purpose;

- long period of operation;

- the presence of manual adjustment;

- the ability to use all kinds of threads.

Disadvantages:

- the impossibility of processing modern types of fabric;

- lack of original instructions;

- difficulty setting up and repairing;

- the inability to simultaneously use different types of threads;

- lack of spare parts.

Despite the presence of shortcomings, this device for many years remains in demand and widely used in sewing production.

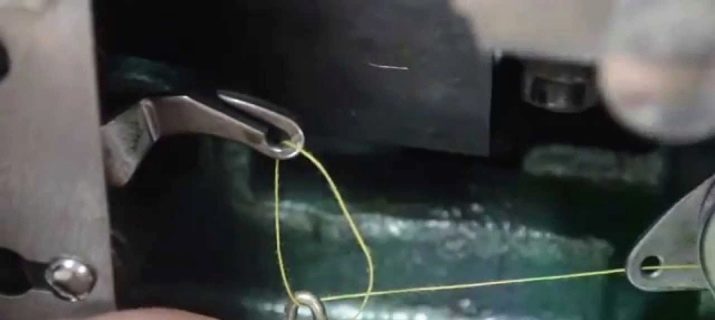

Threading Scheme

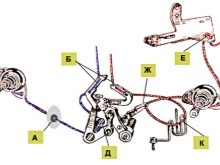

In order for the device to function smoothly, it is necessary to correctly thread the threads. This process consists of the following manipulations:

- needle threading;

- threading the left and right looper.

The main stages of needle threading for three-thread stitching:

- holding the bobbin thread through two holes located on the thread guide plate;

- moving the thread to its side under the tension regulator disk;

- threading through the peephole of the inner horn on the thread guide plate;

- the direction of the thread in the second eye, which is located on the left;

- threading the needle bar from left to right;

- holding the thread in the eye of the needle;

- the establishment of the thread under the foot.

For the first stitches, experts recommend leaving the thread at least 5 cm long.

When threading the left and right looper, the following recommendations should be followed:

- leading the thread from the bottom up;

- removing threads from the housing sleeve;

- mandatory passage of all nodes;

- passing the thread through the nodes in strict accordance with the scheme;

- threading from the back of the looper.

Threading the left loop guide is much more difficult, as access to the looper and thread guide is limited. It is strictly forbidden to pull out old threads and stretch several threads at once.

The correctness of the refueling depends not only on the location of the threads, but also on the correct location of the cam. A shift in the location of this part by several degrees can lead to a violation of the placement of all loopers at once.

Therefore, before refueling, special attention should be paid to the location of this element.

Setup Instructions

Due to the lack of specialists in repair and adjustment of this type of overlock, as well as the high cost of work, the price of which often exceeds the cost of the equipment itself, the owners of these devices are forced to carry out its full service with their own hands. These types of work should only be carried out in strict accordance with the instructions of the manufacturers.

Damage to this type of equipment is a very rare occurrence. All nodes and mechanisms have increased strength and are not able to independently fail. Most of the breakdowns are associated with incorrect handling of the overlock during sewing or tuning work.

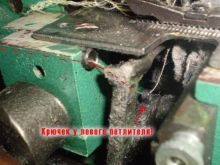

The most important vector when adjusting the device is the location of the left metal hook. In the process of deepening the needle tip to the maximum lower level, it should be in the extreme left position, and the end of the metal hook should be removed from the needle shaft at a distance of 0.5 cm. Raising the needle 0.3 cm above the eye level, a bend should form. The distance between the left looper and the needle should not exceed 0.05 cm. To adjust the gap, use the screw of the left looper fasteners, in the process of twisting which must be turned over at the moment of approaching the pointed needle. Never tighten fasteners or leave them in a relaxed position. After finishing the settings, you need to fix the result.

After capturing the needle loop, the hook on the left pulls it along its razor, and the hook on the right is directed towards it in order to penetrate the loop from the hook on the left.

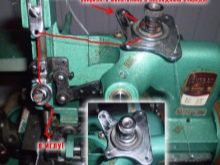

The end of the hook on the right passes through the recess from the inner edge of the hook on the left, tightly located near its hole and razor at the same time. You can verify the correct positioning of parts using the conducted virtual longitudinal strip. The end of the hook on the right should be lower than the hole of the hook on the left and the gap between the blades of both loopers should be no more than 0.16 cm. The final adjustment step is to remove the loop from the right looper with a needle.

When passing the needle into the loop of the right looper, the distance between the needle and the looper blade should not exceed 0.16 cm, and the gap between the eye of the right looper and the tip of the needle should be 0.6 cm.

A distinctive feature of the right looper is the lack of an adjustment screwwith the help of which it would be possible to adjust its location. The adjustment process consists in mechanically bending the device to the desired position.

How to change the needle?

Timely rotation of needles is the key to obtaining a quality line. Experienced seamstresses recommend changing the needle not only when it is deformed and broken, but after a certain period of time, the duration of which depends on the level of intensity of operation of the equipment. Due to the fact that this equipment has a long production time, the needles used must be special, a distinctive feature of which will be a short length and a thickened bulb.

The use of modern sewing needles that do not correspond to the technical characteristics of the equipment can lead not only to getting ugly and wrong stitches, but also to damage the device.

For the processing of dense tissues, experts recommend using needles numbered 100 and 120.

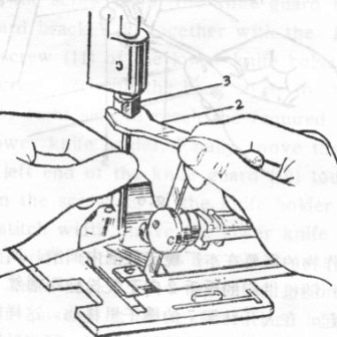

Replacing the needle on the sewing machine is a simple but very important process, which must be carried out in strict sequence.

The main stages of the work:

- removal of the container for scraps;

- the panel is located at the lowest level where the tray with tailor needles and special working screwdrivers are located;

- raising the lever of the pressure plate;

- pulling the tail of yarn from the needle hole;

- lowering the lever of the foot;

- loosening the holes of the mounting bolts by turning the screwdriver counterclockwise.

Before placing a new needle, carefully remove the old sewing element. To install a new needle, you need to take the needle with two fingers so that the blunt part of the bulb is at the back and put it in the cavity under the screw. After carrying out all the above manipulations, it is necessary to securely tighten the fixing screw by clockwise movement. All manipulations must be carried out as carefully as possible so as not to disrupt the threads on the screws. When installing the needle, you must hold it with your fingers as securely as possible and prevent it from falling down.

Failure to comply with the rules for installing the needle can lead not only to the inability to perform work, but also to complete damage to the device. Specialists identify the main causes of breakdowns:

- incomplete needle installation in the needle bar;

- processing with a thin needle of dense tissue;

- strong material tension during operation;

- the presence of defects on the surface of the foot or improper installation;

- the location of the groove of the needle in the wrong position;

- use of a needle of the wrong brand and size;

- work with a deformed needle;

- poor fixation of the needle bar.

How to use overlock?

In order for the purchased device to serve more than a dozen years, experienced seamstresses recommend that you carefully study the manufacturer's instructions and strictly observe all the rules before starting operation.

Basic recommendations for the operation of the sewing machine.

- regular cleaning of the looper and the entire device;

- timely replacement of a tailor needle.

The most common cause of breakage of an overlock of class 51 is improper yarn tension and the use of threads of different diameters. Despite their unpretentiousness to consumables, experts recommend using threads from special industrial bobbins for overcasting. To configure the device, you must first weaken all the nodes, and only then pull each thread individually.

Experienced seamstresses use multi-colored threads to adjust.

The appearance of an uncharacteristic knock during operation indicates the processing of a very thick piece of canvas, when tacking which, a right hook with a foot collides. Ignoring this problem can provoke a failure of the metal looper. Failure to comply with the threading scheme may cause deviations in the functioning of the entire device. To fix the problem, pull the threads out of the machine and refill them.

To prevent pulling out the threads after finishing work with one part, experts recommend not cutting the threads, but carefully placing a new thing and continuing to work. This trick will not only save consumables and working time, but also prevent breakdowns.

If gaps began to appear on the seams being laid during work, the cause of the problem is a shift in the position of the needle bar. You can eliminate the trouble by moving the part down a few millimeters.

Self-made clothing is not only a popular activity, but also very exciting. To obtain a quality result, you need to have not only basic practical and theoretical knowledge, but also high-quality raw materials, as well as good equipment. One of the main technical devices involved in the sewing process is the overlock, with which you can make the product more elegant and durable.

For home use, it is not necessary to purchase expensive equipment, but you can opt for proven models, such as the 51 class overlock.

On how to thread a thread in an overlock of class 51, see further.