The hoverboard is undoubtedly useful, but in some cases it is difficult to argue that it would be better to have some other means of transportation instead. It’s a pity to throw out an old two-wheeled unit, and it’s unlikely that it will be possible to resell for such a price so that you can buy another type of transport. Craftsmen in many cases are not engaged in trade, but in remaking the mechanism with their own hands - thanks to this, it is possible to make the transport change beyond recognition. Consider what can be done from a hoverboard.

Electric scooter

One of the popular options for remaking a hovercraft - production of a scooter with its independent stroke on its base. Such an aggregate does not require passengers to have the same high ability to maintain balance, in this regard it is even simpler than a bicycle, therefore it is in demand.

It should be clarified that in most cases an ordinary scooter is needed to make an electric scooter - it will be the basis for the future unit.

From the gyroscope itself, only the motor wheel is used - Ideally, it should be of the same diameter as the scooter. Experts advise you first to make the rear fork for the motor-wheel of wood or thick cardboard - so you can immediately see your mistakes. And a full-fledged part made of a reliable square pipe will be made according to a previously tested sample.

After the metal fork is cut, welded and ground, a bracket is installed on it with bolts and nuts. Wherein it is necessary to provide voltage to the brushless motor - without a controller, your scooter will remain ordinary, not electric.In terms of power, the controller must match the engine. Most often, it is mounted on the rear plug, which means that you need to lay the wiring along the frame to the gas handle, while the wires are usually fixed with plastic mounts. In a convenient place, plug the charger connector into the system.

Lithium batteries will store the charge of the electric scooter, they can be installed both in parallel and in series. Excessive charge threatens, at best, rapid battery wear, so you need to additionally install the BMS controller - it will not allow excess capacity.

The assembled structure should be carefully tested in a room environment, protected from dirt and dust. If the resulting scooter is working properly, and there are no complaints about it, you need to take care of protecting the main components from dirt and moisture. The cover is best made from a 2 mm sheet of aluminum according to a template previously made on cardboard. In order not to spoil the design of the unit, the cover before mounting on self-tapping screws is painted in a color that logically fits into the color scheme of the vehicle.

Baby car

An ordinary gyro scooter for a small child can be too difficult a test for the ability to keep balance, and even he can not take away two passengers at once. One of the ingenious parents once realized that a small electric car can be built on the basis of a gyro scooter - not only will the design turn out to be much more stable, there are also two places in it instead of one!

The key feature of this solution is that a card is just a “trailer” for a gyro scooter, which means that you can unhook it at any time, again having received at the output an ordinary gyro scooter in its original form.

The beginning of the assembly of the “car” consists in the unwrapping of the rear axle, on which it will be necessary to attach two wheels of the same diameter as the gyro scooter itself.

At the same time, the width of the rear axle can be intentionally increased in comparison with the width of the hoverboard - this increases the stability of the machine and minimizes the risk of an accident. Further, the frame of the future electric car is welded from the profile pipe with a backlog for the front and rear seats. The rear seat usually rises directly above the rear wheels, shock absorbers are built into its supports, designed to soften the shaking for both passengers. Front seat driver it should theoretically be more convenient, because for its manufacture they usually use a ready-made version of the seat with a backrest from anything.

The welded frame is trying on a gyro scooter, and if everything is in order with it, the master proceeds to the next step - the final fit, grinding the seams, sanding any traumatic chipping. After this, it is necessary to weld the floor from a thick layer of sheet metal, capable of supporting the weight of two children. In all cases, aluminum is preferred, because with its low weight it is quite durable and able to withstand the mass of passengers without creating excessive load on the hoverboard engine. After the bottom is welded, you can start painting to give the product a decorative look.

Some masters also consider it necessary to take care of the case in the form of walls and doors, at least not high. In the presence of material, time and good welder skills, they can be done, but it should be remembered that the capabilities of the gyro scooter engine are far from unlimited. Planning to build a whole "convertible", you must be sure of either sufficient engine power or that you are choosing really lightweight materials.

Children's bike without controller

In some cases, the original hoverboard is so old and worn out that it simply makes no sense to update its electronic components.In such an option, it would only have to be sent to a landfill, but an experienced person with hands is able to use it more logically - as a part for the manufacture of a children's bicycle. Such a design, due to the lack of a controller and batteries, will constitute transport, driven only by the efforts of the legs of a small passenger, but he will certainly be happy anyway.

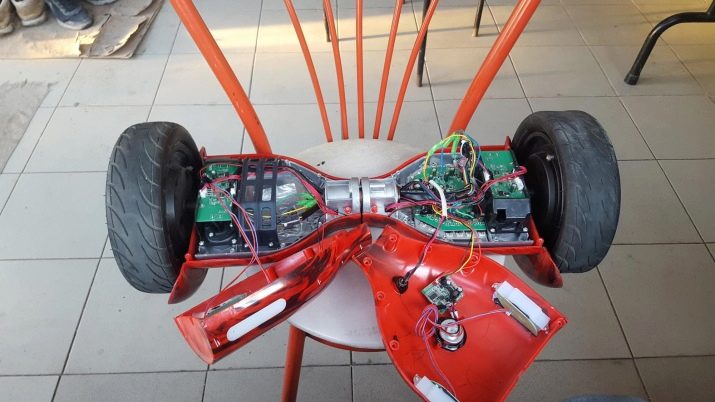

The gyro scooter may not be subject to any structural changes, although it is not forbidden to remove all unnecessary from the case - since the batteries and controllers will not be used for their intended purpose, let them not add excess weight to the vehicle. For the rest, this is a finished rear axle with wheels attached to it.

The task of the craftsman is to find the old one or purchase a new front wheel with pedals, which will replace the missing motor with the new vehicle. Having before your eyes the rear axle with wheels and the front wheel with pedals, you can make An approximate drawing of the frame, so that it fits the small passenger in height. For the manufacture of the frame, it is best to use aluminum profile pipes, since they are both very durable and lightweight - which means that the child does not have to make huge efforts to travel.

If you have never had prior experience in designing such complex mechanisms, you can try to first make all the parts from more malleable materials like wood. Having tried everything that happened, you will see your blots, if any, or you will get ready-made templates that allow you to cut aluminum more accurately.

Having cut out the required number of parts, weld them, try again on the gyroscope and the front wheel, with which they will need to be fastened with screws or welds. All surfaces must be carefully sanded. If you are having difficulty making individual bicycle components, you can buy them in a store (especially for the seat), but it is advisable to foresee this point in advance, otherwise it is not a fact that you can adjust your welding to factory accessories.

Try the construction first without a child - check if the pedals are spinning normally, whether the stroke is too tight, whether it is convenient to turn the steering wheel.

Various additional devices like headlights, baskets or brakes are not needed for a 3-wheeled children's bike, but for most kids it is important that their vehicle looks beautiful, because paint the bicycle frame with bright colors.

In the next video, you will be able to observe an example of creating a machine from a gyro scooter.