Firms producing bicycle tires are guided by the latest achievements in this direction. Their goal is to make the bike an all-weather and all-weather vehicle and sports equipment. Differences between tires for different purposes - studding, pattern and aggressiveness of the tread, the layered structure of the product itself, etc. - and not just the width of the rubber and the diameter of the rim.

Types of Tires

For many cyclists, a fat bike is more often associated with winter skiing on snow, mud and slush, and summer trips through fields and forests. They recall that on a fat bike, the tread must be aggressive, like mountain bikes, for riding on bad roads and off-road. In fact, a fat bike will pass along a snowy highway. This is where slick or half-slick tires come in handy - their patency is higher than if the same bike passed along autumn or winter impassability. In the slick, there is no protector, in the half-slick it is not high, it protrudes only 2-3 mm. The latter is ideal for traveling on asphalt interspersed with exits on unpaved roads.

For riding on ice as smooth as glass, rubber for a fat bike must be studded - it will prevent falls on ice. The length of the spikes is equal to or more than 0.5 cm.

Rubber purpose

For riding on paved streets suitable slick. On smooth roads with perfect coverage, the tread is not needed - it will only interfere with acceleration. On dirt and gravel roads, if the weather suddenly turned bad and the road turned into a mess, an aggressive and pronounced tread would help out. The semi-slick tread is suitable for dry roads with dirt, gravel, as well as for rocky driveways or old, cracked asphalt or concrete.

Beginners often try to ride in the summer, when the roads are dry and free, on studded tires. In this case, the tire will seriously suffer - the cyclist will spend a lot of effort during acceleration, because the spikes, like lugs, will row along the asphalt, and this is about the same as driving an asphalt roller to the place of work, with bristles instead of smooth wheels and nails welded to the undercarriage of the same wheels. As a result, the speed of movement of such a vehicle will noticeably decrease. The situation is reminiscent of the one in which the same biker moves on a road bike, on which, instead of a smooth slick, an aggressive tread.

Composition and ply

Bottled rubber is used to produce low-cost tires. It is not particularly flexible, subject to faster drying and abrasion. Synthetic rubber with the addition of butyl - the starting material for the manufacture of cameras, including for the same rubber used for fatbikes. Its main disadvantage is the larger weight of the wheel: bottled rubber is noticeably heavier, and such a tire weighs 300 ... 500 g more.

Tires with Kevlar have a much greater margin of safety. Kevlar threads penetrate the cords of many models of tires of the middle and higher price ranges. The number of layers with Kevlar threads can reach three - this gives the tires special strength. Kevlar layers are characterized by the most important indicator - the number of threads per square inch, or TPI. It varies from 30 to 120. The final price of one such tire - except for the composition of the rubber - is determined precisely by the value of TPI. Aramid threads are less commonly used.

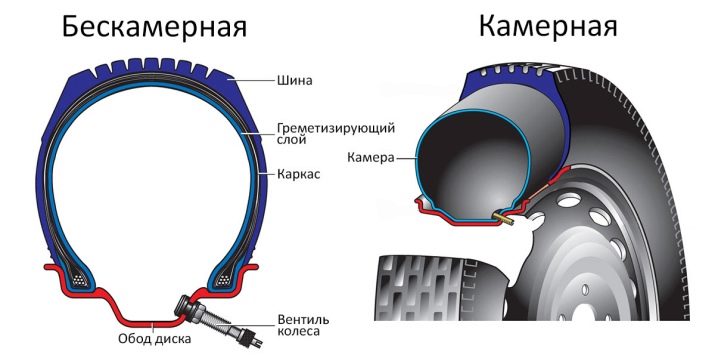

Camera availability

Chamber bicycle tires - a classic of bicycle and automobile rubber. Nevertheless, tubeless technologies did not bypass bicycles. The lack of a camera reduces the total weight of the bicycle wheel by a maximum of several tens of grams, allows you to repair a punched wheel, pouring sealant into the puncture and without removing the tires from the rim. For people who care about the speed of the process and the quick availability of a bicycle to continue their journey as if nothing had happened, a tubeless tire is the best choice.

Avoid installing tubeless rubber on rims not designed for such tires. The rim on ordinary wheels is simply not suitable for tubeless rubber - it will quickly bleed air, even if you try to put it “stretch”. This is due to the perforation of the rim - spokes with screw threads come into it, and these holes for them are not sealed. The fact is that with tubeless wheels, the spokes are fixed in a different way - their mating points do not let air out of the space in which this air must be under a certain pressure.

In addition, due to the special structure, the tubeless tire will not withstand long cycling with wide rims - excessive flattening will destroy these layers prematurely.

Size ratio

If you try to put on a tire with a diameter of 27.5 inches on a 28-inch rim - you are guaranteed to break the cord and stretch the side of the cable. On the contrary - it will not stay on the rim, at the first collision with the slightest roughness it will "move" to the side and take off by itself.

The width of the tire is selected for the gap between the feathers and the frame dropouts, as well as for the gap between the “legs” of the fork. Too thick, for example, 4-inch, when you try to turn a mountain bike into a fat bike - after pumping it will get tight, it will jam, and the bicycle will not ride. Wider tires roll better on bad roads, up to dirt and snow drifts, narrower - only on paved streets and highways, with a stretch - on dry unpaved roads, however, they are not at all suitable for sand.

Adhesive for sealing

Having chosen tubeless rubber for fatbikes, immediately pick up a good glue. The fact is that tubeless tires require additional sealing. Without it, attempts to pump such a wheel are similar to the desire to fill a barrel without a bottom with water. In the old adhesive, the expiration date of which ends, the structure is violated - it coalesces and delaminates.

When applied to rubber, the old and caked adhesive will not connect the gaps, but will destroy the tire layer by layer.

Conclusion

Whatever tires you choose for a fat bike, focus on your riding style, daily and annual mileage, road quality and weather. The best solution is to have two forks for the same bike for summer (slick or half-slick) and for winter (studded tires with mud tread). This will help you quickly adjust to the actual driving conditions.

On how to choose winter tires for a fat bike, see further.