Corrugation is called pipe with a series of parallel protrusions. Among its main advantages are flexibility, durability and ease of installation. Pipes of this kind can be used in almost all types of construction work. The degree of flexibility of the corrugation is measured by the height and number of ridges - the more there are, the more the pipe bends. Today, among the employees of repair organizations, the toilet corrugation, created to facilitate the installation of plumbing equipment, is especially popular.

What it is?

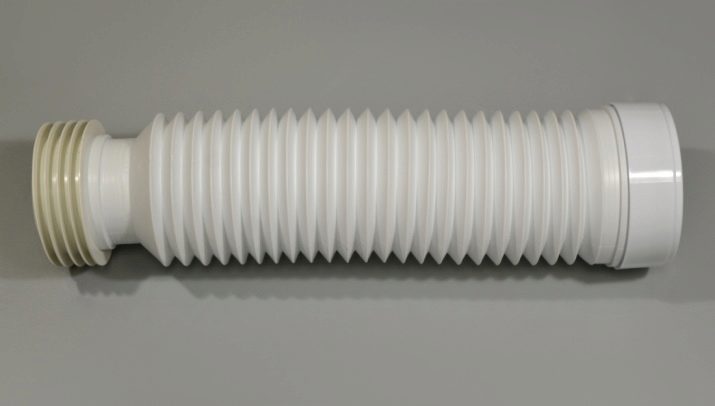

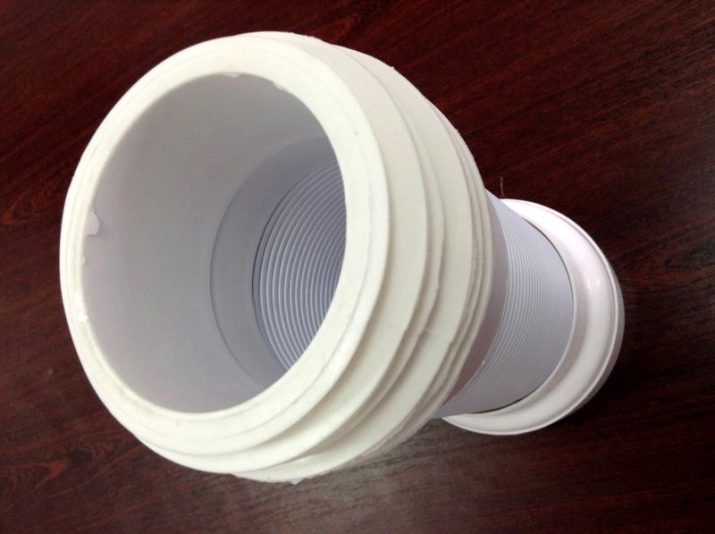

Corrugation for the toilet is considered an unchanging component of a set of professional plumbers. She looks like a wide and quite flexible sleeve. The main purpose of the part is to ensure uninterrupted flushing from the toilet. This strong and extremely lightweight part replaced the inefficient sewer structures that were used at the beginning of the twentieth century.

It is worth noting that before the appearance of the corrugation, the independent replacement of the toilet bowl was comparable to a real feat. It was not possible to carry out a replacement without completely destroying the fixtures and tiles. The new drain hole had to exactly match all the measurements made, and its coincidence with the sewer discharge from cast iron alloy was considered mandatory. There was no way to do without professional plumbing. However, today the presence of plastic corrugations allows you to repair plumbing even to home craftsmen.

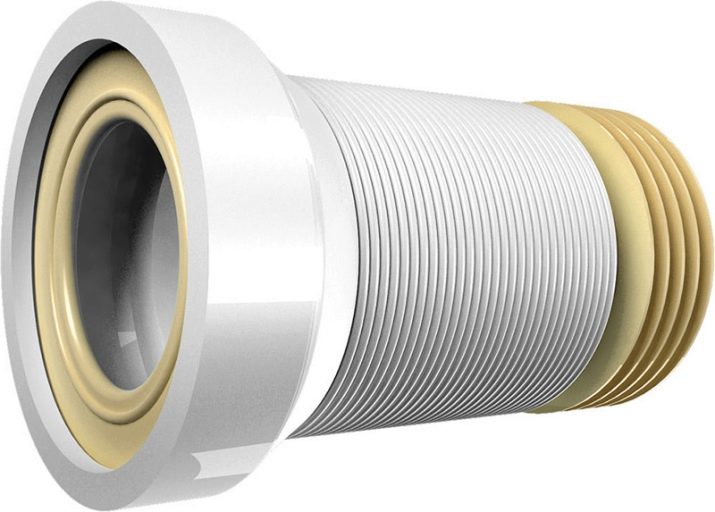

An extension with an internal seal at one of the ends of the pipe allows you to put on the corrugation on the toilet.A rubber coupling is also placed there, which facilitates the process of attaching to the riser and seals the resulting structure. Pipes easily fit into any design, which makes the installation process of plumbing quite simple.

Advantages of the corrugated pipe for the toilet:

- low cost;

- ease of installation;

- the possibility of use in difficult situations where the installation of a bypass system or pipe is impossible;

- no additional fixtures and actions will be required (for example, welding pipes made of cast iron);

- the inside of the corrugation is smooth, so waste will easily pass through the pipe;

- easy dismantling;

- corrugation is perfect for both temporary and permanent bathrooms;

- it uses materials that are safe for human health.

The disadvantages of the corrugated pipe.

- Not too high degree of strength. Even a small piece of glass or wire can damage the pipe.

- Sensitivity to hot water, which can cause deformation of the plastic surface.

- A strongly curved corrugation can aggravate the formation of blockages.

- The long pipe sags, forming blockages. You can install a system of backups, but this will not greatly change the situation.

- The appearance of the corrugation is not particularly aesthetically pleasing.

- Sewer cleaners lead to depletion of wall density. The result is permanent leaks.

- A black coating appears through the material.

- There is no possibility of mounting the transition system from the inside of the walls.

What is it for?

Corrugation is indispensable in cases where the toilet cannot be fixed directly above the drain hole. Corrugated pipe can also be used for floor deformation. Similar situations occur when floor tiles are laid without dismantling the old one, directly on top of the previous finish. Another reason for using the toilet corrugation is the rearrangement associated with the appearance of new elements in the room. This can be a washing machine, shower, dryer and other items.

Residents of old apartments may face the following problem - the hole in the new toilet does not fit the existing sewer system. Such a difficulty often arises among owners of apartments in houses built back in Soviet times. In those years, toilets installed toilets with an oblique hole. Most modern plumbing equipment has direct releases.

Corrugated pipes are indispensable when creating temporary toilet stalls for social events. These parts are easy to install and low cost. Among their main disadvantages are deformation at too high temperatures, low strength and the likelihood of clogging with strong bends.

Varieties

Corrugated connecting systems differ among themselves with the raw materials from which they are made, as well as with the method of fastening. For example, for the owner of a small room, the best option would be a pipe with such a branch, which will allow you to connect two parts to one passage of the structure at once. During installation of a corrugation of this kind, a special rubber cuff can also be useful.

The cost of even the most expensive element of the sanitary construction is relatively small, so you should not skimp. It’s better to overpay a little for it, but to achieve high quality than to suffer later, fixing numerous defects.

Corrugation of modern European manufacturers for the most part is assembled from a reinforced base. It is reinforced with a special flexible metal wire. This model is rigid, its structure does not sag and resists aggressive external influences.

Pipes from polypropylene raw materials very soft. Their rubber base is extremely flexible. Such corrugations are popular when installing temporary toilets at fairs or other social events.

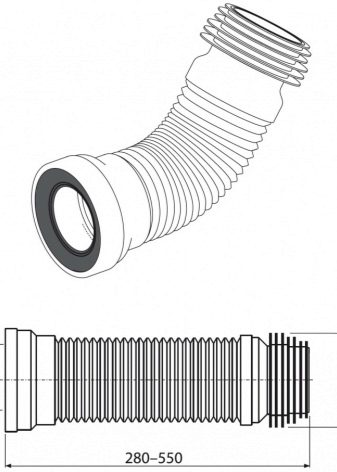

Elbow Corrugation used in cases where the sewer system is located too close to the fastening area with the toilet. Its main function is to provide a strong bending connection. During installation, you may need a toilet clown, which will provide good tightness. The element consists of two cylindrical tanks, one of which is located as close as possible to the instrument outlet, and the other to the sewage pipe.

It is worth considering that at present the only possible alternative option for the corrugation is angled pipe made of plastic. When it is installed, a rubber cuff and sealed serum are used to seal the joints. Here, pipe parts and branch systems also require special sockets.

A rigid pipe is stronger and looks more aesthetically pleasing. However, its main disadvantages are the bulkiness and the fact that when replacing only one pipe, it is necessary to dismantle the entire system. Vertical rigid models are installed quite rarely, and if this happens, then only in private homes. The reason for this is the need to completely open the floor during dismantling or other repairs of the sewer system.

Dimensions

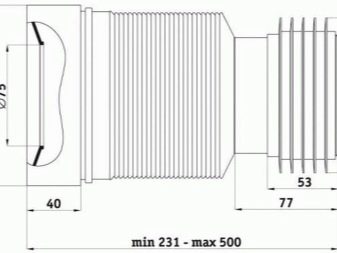

The length of the corrugation for the toilet is the most important indicator that should be taken into account when choosing this part. The two main categories of corrugation sizes are short and long. The standard sizes presented on the modern market vary from 230 to 500 millimeters. The first value is the shortest, less choice does not make sense.

The diameter of the cuff is usually 135 mm. The diameter of the end that fits into the sewer pipe varies from 100 mm to 110 mm. The parameters of the attachment nozzle are also unstable - their length can be from 50 mm to 70 mm.

Popular models

Import manufacturers do not save on the amount of reinforced wire during the assembly of equipment, which significantly improves the quality of the product and increases its service life. So, the popular Czech AlcaPlast company produces not only reinforced corrugation, but also made in a custom design. It is noteworthy by the method of attaching a corrugated pipe with a bell. Its diameter is 110 millimeters.

When mounting additional parts can not be used.

Highly appreciated corrugations, which can be easily adjusted to any riser regardless of its material of manufacture, whether it is plastic or cast iron. The wall thickness is significant - the more it is, the longer the product will last. Reinforced models from AlcaPlast with thick walls are most in demand.

How to choose?

To the owners that they decided on an independent repair of plumbing equipment, choosing a corrugation for the toilet, should pay attention to such features.

- Degree of hardness which directly depends on the materials used in the manufacture of corrugations. Plastic products are softer, thinner and more elastic. They are suitable for all types of toilets. Reinforced pipes are more rigid, although the thickness of their walls does not differ from the thickness of plastic. They have good wear resistance.

- Reliability, which is also affected by the material of construction. Corrugations equipped with reinforced wire are more rigid, which means they are stronger and more durable, even if they are mounted with an offset.

- Length it is worth choosing, focusing on the distance between the toilet and the drain pipe. Do not forget that the corrugated connecting system can not be greatly stretched, as this will negatively affect the time of its use and the appearance as a whole. Stretched corrugations can sag and leak more often.

Additional components that are not always required during installation.

- Coupling, which connects the sewer to the toilet. It should be purchased if the elements of the system are located at a very close distance.It can be straight or eccentric.

- Cuff connections or return systems with non-return valve. The parts are designed for a displaced toilet. They are usually made of plastic.

During installation, the optimal length of the part is especially important - it should not be too long, but not too short. The material used in the manufacture of both the corrugation itself and the peripheral structural elements must also be flexible, but at the same time durable.

Installation Recommendations

When a sewer system is replaced, rather than installing a completely new design, dismantling is mandatory. It is required to completely shut off the water supply, as well as drain all the water from the tank.

In the hope of long-term operation, the toilet bowl is often fixed with cement, which makes disassembly difficult. To facilitate the process of dismantling the object, you need to lightly hit the throat element of the toilet bowl with a hammer. The vibration resulting from the impact will affect the cement.

However, it should be borne in mind that it is impossible to hit the sewer pipe in any case, otherwise it will crack.

Before installing on the edge of the corrugation, a small amount of sanitary sealed mixture, which is based on acrylic and some silicone components, should be applied. Such a composition will provide a high tightness of the dock, because it is specially designed for conditions of high humidity. Next, on the smeared surface of the outlet edge of the system, it is necessary to put on a pipe, turning it to the toilet bowl on the side on which the inner membranes are located. The corrugated system should block the toilet outlet by about 5-6 centimeters.

Upon completion of the installation, check the quality of work. To do this, water is supplied to the tank and flushed. If fluid does not leak at the joints, the joints are tight. Otherwise, there are leaks. To eliminate them, it is required to process problem areas with several layers of a sealed mixture.

Stretch the pipe before the direct process of connecting to the sewer system. To avoid blockages, control not only pipe slack, but also all slopes. Mark the points on the floor for fastening the toilet, after disconnecting the pipes. Drill the holes obtained and coat with a sealed mixture. Attach the toilet by pulling the mounting bolts to such an extent that the plumbing ceases to stagger and stands level.

Be careful: if you overdo it, then the foundation may split.

Reconnect the adapters by treating the joints with a sealed agent. After this, carry out a leak tightness test again. Fill the screed and do the final finishing work on the floor.

A particularly important step is the installation of the cuff. The level of sagging depends on the degree of stretching of the corrugation and technical characteristics. The tensioned joint is highly susceptible to deformation. For this reason repairmen strongly recommend that during operation of the system avoid unnecessary stress on the structure.

It should be prepared for the fact that in the sagging corrugation, so-called “pockets” can form, in which harmful deposits accumulate. This leads to ruptures of its walls. It is necessary to prevent the consequences of this kind of additional clamps. In difficult cases, you can buy bent sockets with a bend angle of 45 degrees (according to GOST).

It is also worth noting that vertical sewer structures are usually somewhat more aesthetic and often fit much more nicely into the design of the toilet room. The use of toilets of this kind is simpler, and cleaning takes less time.

See how to connect the toilet to the sewer in the next video.