Thanks to the development of modern technology, the impossible becomes possible. Scientists were able to create a new generation of fabric. Thanks to the use of high technology from eucalyptus wood fiber, a very interesting and extraordinary fabric was obtained - lyocell. In the age of active consumption, alternative materials are becoming increasingly popular.

What it is?

Most often, a simple layman divides the material into cotton and synthetics. Quite recently, a completely new matter has appeared, which was created through the use of high-tech techniques. The product of modern technology is called "lyocell."

It is a fiber made from cellulose, which is obtained during the chemical treatment of eucalyptus trees. Due to such features, the fabric can be considered completely safe. This is a fairly serious invention in light industry over the past decade. The product was developed by scientists in the 80s. 20th century. Industrial production of the material began to develop actively in the late 90s. 20th century. In Russia and the USA, the material is used under different brands. In our country, lyocell has the name "orcel" and was created in Mytishchi (Moscow region). The second name - “Tensel" - the product received in the United States.

Bedding made from this material is very popular. Getting such raw materials from eucalyptus is very expensive. This is due to the high cost of wood and the use of high technology in production.However, in production, it is practically not necessary to use strong chemical components. Due to such production, plants do not affect the environmental situation, and the fibers have a clean composition.

By its properties, lyocell is not inferior to cotton fabrics, and in some nuances it is even better than them. Lyocell has the high antimicrobial properties that eucalyptus is famous for: the material is quite durable, does not cause an allergic reaction and is quite universal. In addition to creating premium fabrics, filler is made from it.

Important: this type of fabric belongs to artificial, but has all the characteristics of natural materials. Lyocell has high strength (like synthetic fabrics) and is very unpretentious in the process of use. In its market niche, lyocell is the best material for the production of clothing and bedding.

Composition and production technique

Surprisingly, the production of new material is completely environmentally friendly. Even environmentalists have been forced to admit that the production of this product is completely safe. The product has even been awarded a special environmental award established in Europe. The basis for obtaining the material is natural production technology. Quite a lot of money is spent on the production of this material. But at the same time, nature does not suffer at all. The material is completely harmless to children and adults.

The main stages of obtaining material.

- The very first step is dissolution. This is done in the process of treating wood with water to produce pulp.

- The next step is the evaporation and mixing with an organic solvent. The whole composition is heated to +100 degrees, and then cooled in special containers.

- When the suspension has cooled, it is filtered and then melted.

- The product is pulled in the axial direction, fiber is formed from it. Thus, the interconnection of molecules is destroyed and new ones appear, but with special crystallization.

Important: harmful substances do not appear at all in the production of lyocell.

Lyocell is formed from the fiber of the same name with the help of several variations of weaving on a loom. Similarity with cotton, sateen and silk depends on the characteristics of raw materials. The result is a very light, soft and silky fabric. It combines the best properties of natural and artificial raw materials, due to which it is popular throughout the world.

The composition of the material depends on the manufacturer. This type of fabric can be sold in pure form or mixed with natural and artificial elements. In the form of additional raw materials, cotton, viscose, polyester, etc. can be used. Lyocell without additives is a very expensive product, therefore, it is rarely sold in this form. Mixed material variants are widespread:

- with the addition of elastane;

- with the addition of elastane and modal.

The percentage of lyocell in the material can be varied. Usually it is not less than 50% of all components. More detailed and accurate information should be on the product label.

Fabric properties

Through the use of modern technology, scientists were able to produce fabric similar in appearance to silk, and in strength - similar to satin. It also has the natural properties of cotton fabrics.

Key properties of lyocell:

- the fabric is very durable and does not tear even when wet;

- the fabric has high hygroscopic characteristics;

- the material can be used as part of medical bandages;

- due to its excellent characteristics, it is great for people who are allergic to synthetic materials;

- items sewn from this fabric can be worn even by children;

- the material does not attract dust, which contributes to the even greater use of lyocell in light industry;

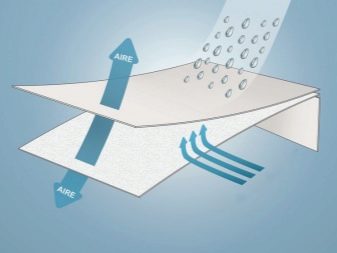

- the material passes air well - thanks to this property of the product, pillows, mattresses and blankets were made from it.

After creating the fabric, scientists wanted to replace them with viscose materials used for sewing clothes. But soon, thanks to a detailed study of the characteristics of tissue, it began to be used in many areas of human life. Currently, covers and blankets for vehicles made from lyocell are very popular. The fibers of the material are used in the manufacture of filters for air ducts. And due to the silkiness of it began to produce items of underwear and bedding. Due to the properties of the material, it is possible to make clothes for children, elegant dresses, as well as warm and durable sweaters.

Advantages and disadvantages

Thanks to the use of modern technology, excellent fabrics are produced from lyocell that are incredibly pleasant to the body and have good hypoallergenic properties. The appearance of the material can come out completely different: from fluffy and smooth to imitate leather and suede.

The main advantages of this type of fabric:

- the material is very comfortable to wear;

- things from such a fabric have a high-quality and dignified appearance, they are worn well for a long time;

- the material has a wide range of colors and does not lose brightness after many washes;

- the fabric almost does not crease;

- lyocell perfectly retains its shape - the material does not roll into spools with long wear;

- tissue has bactericidal properties;

- The material allows air to pass through, making you feel comfortable.

The disadvantage of this fabric is a little shrinkage. It occurs with improper washing. Mold may develop if stored in an inappropriate place in high humidity.

Lyocell filler has a number of undeniable advantages:

- does not allow the formation of harmful microbes and ticks;

- very light and warm;

- has high breathability;

- quickly restores shape;

- lumps do not form during use;

- has a long service life.

There are no disadvantages from using such a filler. The only drawback is the high cost, which may make it inaccessible to some categories of citizens.

Experts say with confidence that this type of material is not harmful. Bed linens made of such a fabric are recognized as one of the best. The product is recommended to all lovers of natural, comfortable and environmentally friendly materials. This material, which perfectly passes air, has antimicrobial and anti-allergenic properties.

Where is it used?

Initially, the material was created for the production and sewing of clothes. But due to the strong similarity with silk, manufacturers began to make bedding from lyocell. Consumers appreciated the beautiful appearance and pleasant texture, as well as good performance and hygienic characteristics of the material. Thanks to its special structure and hypoallergenic characteristics, lyocells are an excellent filler for any pillow. Often you can find a blanket filled with lyocell. Bed linen made of lyocell does not roll, contributes to high-quality air exchange. To reduce the cost of eucalyptus filler, hollofiber is often added to the composition.

Clothing for children and adults can be completely different. This is affected by the characteristics of the material, which allow it to be smooth, radiant, fluffy and very soft or imitating suede and leather. Even with the use of additional impurities, the fabric is strong and flexible. She perfectly fits the silhouette and drapes beautifully using the most standard patterns.

Terry fabrics have wonderful softness and perfectly absorb moisture. Clothes and bedding from this material are very strong and durable. But they require proper and quality care.

How to care?

The material is quite resistant to mechanical damage, but do not over-test the product for strength. It is important to observe the simplest rules when washing, during ironing, during storage and wearing. Due to the observance of the rules of gentle care, things from this material can last a long time, while maintaining their appearance.

Basic rules for the care of products made of lyocell.

- The place where the product from this fabric is stored must be dry. If the fabric lies in a damp place, then mold quickly forms on its surface. This is due to the hygroscopic characteristics of the material.

- It is best to wash clothes from such material manually or in a typewriter, but in a delicate mode. It is necessary to wring out products at the minimum turns.

- The temperature for washing should not be more than 40 degrees.

- Dry the product in a vertical position or completely decompose on a horizontal surface. Avoid direct sunlight.

- It is not recommended to iron at maximum levels. You can use the mode for ironing silk items.

- Pillows need to be often aired and dried in the sun.

- If the fabric is mixed, then you must adhere to the rules for caring for additional elements of the composition.

Comparison with other tissues

This product has all the advantages of natural and artificial fabrics. Many experts claim that things from this material can be strong competitors to products made from natural components. The material is very soft, elastic, with excellent gloss. It can be warm or light.

The main differences of lyocell from other materials:

- has a soft surface;

- does not slip like silk;

- the material has greater elasticity and is much more hygroscopic than cotton;

- has an increased criterion of moisture absorption;

- when wet, it is 3 times stronger than viscose and cotton materials;

- possesses greater durability in comparison with fibers of natural materials;

- lyocell lets in more air and does not attract dust.

This is a real product of modern production and use of high technology. The material has incorporated all the most worthy qualities of natural eucalyptus wood and modern fabric manufacturing technologies. This indicates a high competitiveness of the material.

Reviews

In general, based on customer reviews, lyocell products are very popular. The material has high adaptability, hypoallergenicity and environmental safety. These characteristics are basic for many mothers when choosing clothes and bedding for their children.

Many buyers note the high quality of the material and the preservation of bright colors on bedding, even after many washes. Items made from this material are in great demand. They have a long service life and keep their shape perfectly even after washing. Simple-cut dresses look very impressive and stylish due to the pleasant shine and radiance of the fabric.

Among the shortcomings, many consumers noted a high price for products made of this material. Things from lyocell should be washed and ironed carefully at gentle temperature conditions. The material is demanding on storage conditions. It must be kept in a dry place, otherwise mold may form from moisture.

About what properties lyocell tissue has, see the next video.