In the modern world, cotton is the most common and common name for a fabric. It is familiar to every person, without exception. But as soon as the phrase “cotton fabric” or its abbreviation “cotton” appears in the conversation, many people start to ask different questions. It is not clear to many whether there is a difference between these types of fabric and what is the peculiarity of each individual material.

In fact, the majority opinion looks completely ridiculous. Cotton and cotton fabric are one and the same type of textile product with different names. They make it from cotton, or rather, from its fruits. The quality of the material is determined by the length of the fiber - the longer it is, the fabric becomes stronger and more durable. Even at a cost, cotton products are much inferior to their counterparts.

Due to these features, cotton fabric is considered the most common type of matter to this day.

What it is?

Cotton is considered one of the oldest types of fabric used by mankind for sewing clothes. Work with this material began to be mastered even at the dawn of the emergence of the civilized world. But despite this, cotton production for a long time did not have industrial proportions. The first mass crop of cotton was harvested in India. In Europe, he appeared a little later, to be more precise, during the reign of Alexander the Great. After some time, European craftsmen were able to understand and master the principle of manufacturing and sewing cotton products, after which they managed to establish domestic production.

Cotton material appeared in Russia in the 15th century, but its production was rather scarce. That is why the material was considered the most expensive.

Initially, the processing of cotton fabric was carried out manually. This was the most important and fundamental of the reasons that hindered the distribution of fabric on the world market. Then the situation changed radically due to the beginning of the advent of industrial equipment for the corresponding processing methods.

The established process for the production of cotton matter provided for step-by-step actions.

- Harvesting. This refers to the weighing of the procurement material and its storage.

- Cleaning up. Various garbage was removed on the corresponding machines, after which sorting was carried out.

- Making continuous threads. This process speaks of interweaving of fabric fibers.

- Weaving threads. Directly creating fabric.

Today, the cotton production process proceeds exclusively on an industrial scale. After each individual step, technologists carry out certain checks, based on which they make notes and make a description of the products being prepared. The finished material not only looks spectacular, but also has a host of other advantages, which can be felt with tactile contact.

Structure

In the modern world, it is very difficult to find clothes or any other textile item made of 100% cotton. Quite often, during the manufacturing process, some components are added to the fabric, due to which the finished material is obtained with higher quality, has an increased level of strength and has an appropriate form.

To a greater extent, cotton is supplemented with such fabrics as viscose, polyester, acetate. Knowing their features, you can understand why cotton products have many advantages. Firstly, the material is less wrinkled, which is very important in the modern rhythm of life. And secondly, there is an opportunity to increase the color palette.

That is why cotton clothes and textiles can be presented in the brightest and most juicy colors.

In any store of men’s, women’s, and especially children's clothes, sellers quite often offer their customers ordinary things made of synthetic material for natural 100% cotton. You can take their word for it and, after the first wash, give an appropriate assessment of the purchased item, and the seller too. On the other hand, in the selection process, you can conduct some tests to determine whether high-quality and 100% cotton is presented in the window or is it still synthetic.

First you need to carefully look at the material. Cotton itself does not even have a minimal sheen. If unpleasant spools are present on the fabric, then there is no cotton in the material. Another way to check the quality of the composition is to crush a small piece of clothing in a fist. If the fabric is wrinkled, then one hundred percent cotton was used in production. The latest way to check the quality of the material is to wash it. This experiment will be possible only after purchase.

Items made from natural cotton dry very slowly, while synthetic fabrics dry instantly.

Advantages and disadvantages

Like any material, cotton fabrics have certain advantages and some disadvantages. Undoubtedly, a high level of strength and quality, as well as an affordable price, are important advantages.

Along with this, he has some negative characteristics. Prolonged exposure to sunlight on cotton fabric adversely affects the density and quality of the material. Any cotton products must be treated with different compositions that do not allow the fabric to wrinkle. The most unpleasant thing is the destruction of cotton fabric due to the appearance of harmful microorganisms in it. This process takes quite a long time, abrasions first appear on the fabric, then small holes. With proper care, the destruction of clothing and any other unpleasant consequences can be forgotten forever.

Species and their properties

Today, there are enough parameters due to which you can get a variety of types of fabrics with a base of pure cotton. The production of textile raw materials due to the addition of natural, chemical and synthetic components has increased several times.

- Batiste. A very subtle form of matter, but quite durable. It has a low level of density. It is made from combed yarn subjected to preliminary torsion. The type of weaving used is plain, due to which low density is obtained. According to the price criterion, the fabric is very expensive, but very wear-resistant. Of the cambric, they mainly produce sleep accessories - shirts for women, pajamas for men, and tablecloths.

Marquette material is mainly used for sewing summer clothes, as well as curtains and bedding.

- Marquette. This type of material is much like a cambric. In its production, the same combed yarn with plain weaving is used. The only difference is a higher level of twisting of the threads.

Marquette material is mainly used for sewing summer clothes, as well as curtains and bedding.

- Volta. It is a silky and very delicate material with a high level of density. It is made using combed yarn, which is preliminarily tightly twisted. The main characteristics are much like a cambric. Underwear is made from volt.

- Percale. A very refined and very sophisticated form of matter with a high level of density. The weave of fibers is made according to one algorithm. Despite its strength, it seems very soft and silky. Percale products will last their owner for a long time. Despite its sophistication, the fabric easily tolerates washing and many cleaning methods.

- Poplin. This material is made on the basis of plain weaving of combed yarn. Bedlin is made from poplin.

- Kisei. The material is very light and transparent. Weaving takes place using a special technology. The threads are intertwined in pairs with the crossing of the warp fibers. The fabric is used to decorate women's costumes, as well as curtains for windows.

- Tulle. Transparent, light and delicate patterned material. Its production takes place on specialized machines. This fabric is mainly used for decorating women's clothing, curtains on windows, as well as for bedspreads and wraps.

- Guipure. A very famous fabric. It is an elegant material made of thin threads. For its production, several methods are used. The first is the removal, that is, the tearing of the fiber, the second is the dissolution of the threads in the form of a pattern.

- Combed satin. The name itself reads the essence of fabric production. The material is made from combed yarn using satin weaving. It is mainly used for the manufacture of bed linen and any other home textile products.

A fairly large variety of textile products is made from medium fiber varieties of cotton.

- Chintz. Well-known matter produced from threads of medium torsion. Chintz is used in sewing summer clothes.

- Calico fabric. This is a whole group of weaving fabrics, similar to chintz material. From calico fabrics produce textiles for household goods.

- Calico Russian material is made of pure cotton. The imported coarse calico incorporates a certain amount of synthetic fibers.

- Cardin satin. Dense matter made of thickened threads.

- Cretonne. A fairly dense and pre-dyed type of fabric, the weaving of which is performed according to the linen type. The result is products with an ornament and various patterns. It is used for upholstery.

Particular attention should be paid to the American type of stretch fabric. The most advanced technologies are used in the production of this fabric, while cotton is combined with elastane.

Recently, Polish material Polycotton is gaining wide popularity. Its feature is the combination of cotton with polyester in equal quantities.

Comparison with other materials

Each cotton fabric has certain distinctive qualities peculiar only to it.

First you need to consider the combustion process. In principle, any natural material has the property of complete combustion. Products consisting of a mixed composition burn out with the formation of droplets of resin. But synthetic fillings do not burn at all, they only melt. In the process of burning, the smell of burning paper comes from natural cotton. After burning through most of the fabric, the damaged material begins to smolder. For comparison, you can check flax - it burns well, only the residues smolder much worse. For another comparative example, it is proposed to consider wool. This material burns out almost immediately and completely. At the same time, a terrible smell of burnt hair exudes.

Another distinctive feature of cotton is its tactile feel. The touch of cotton causes the most unusual, soft, warm and delicate sensations. For comparison with other types of fabric, it is also proposed to consider flax. With tactile interaction, flaxseed material seems rather rough, stiff and slightly cool. But none of these types of fabrics can be compared with natural silk.

Cotton material is hygienic, practical and very beautiful in its properties. Thanks to a wide range of products, you can always choose the most comfortable things that will meet all the requirements of its owner.

Anyone can buy cotton clothes or other textile products from him at the most affordable price.

Where is it used?

Arriving at the store selling any fabric products, several questions immediately arise, and the main one is the presence of cotton fabric or any elements of natural cotton textile. In fact, cotton is present in almost all products that people use. For example, bedding. For their production, soft grades of fabric, for example, satin, calico, are mainly used. For a children's bed - exclusively flannel. Cotton material is quite light, so it is used in the manufacture of summer dresses, men's shirts. In hot summer weather, in cotton clothes, everyone feels cozy and comfortable.

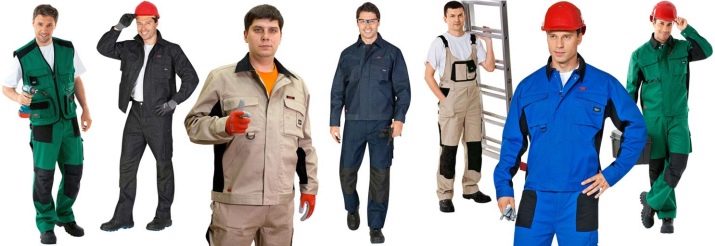

For sewing outerwear, cotton fabrics are often used. Many companies use exclusively cotton material when ordering uniforms for their employees.

In household use, almost any textile element is cotton, for example, tablecloths, curtains, towels, curtains and much more.

Care

Like any other material, cotton requires special care. For example, so that the material doesn’t sit down, white cotton items need to be washed at a temperature not exceeding 95 degrees colored - at 60. But thin clothing options - at a maximum of 40 degrees.

It is best to wash cotton fabrics in a washing machine. In addition, the automatic system allows you to set the required washing mode for each individual type of laundry.

For any kind of cotton, you can use additional cleaning products that can soften the water in the machine, thereby giving extra softness to washable clothes.

In no case should colored cotton fabrics be washed with bleach or delicate detergents. Drying mode is allowed only for some types of cotton fabric. Information on this can be found on the label of textile products.

The neglect of the fabric leads to the fact that the material sits down after washing, respectively, the size of the item changes and the symmetry of the product is violated.

Master - class for sewing bedding, see the next video.