A universal twill fabric consisting of mixed fibers is often confused with pure wool tweed. The thing is in consonant names, since the composition of these two fabrics is completely different. There are no reliable sources about the origin of twill. According to Edward VIII, in his author's book “Remembering Windsor”, in 1830 a twill fabric from Scotland was sent to a London merchant, designating it Tweels. By negligence, the Englishman mixed up the name with Tweed, and for a long time the material was successfully sold under this brand.

Description

Because of this oversight, many people who are far from sewing and material science still confuse twill with tweed. Nevertheless, this fabric is not made of wool, but by mixing several types of fibers with a twill diagonal weave. On the product label is usually indicated the full composition of the matter.

During its existence, the fabric has undergone many experiments regarding the raw materials used and production methods. Initially, for the production of twill, coarse and thick threads were used purely in gray-brown dark tones. In composition it was 100% sheep wool, woven so that it attracted attention with a special texture - in a herringbone or the so-called crow's feet.

With the development of technology, woolen thread began to be combined with silk and cotton fibers. This greatly expanded the range of production of things from twill. Now the material was used not only for sewing classic costume dresses for business people, but also for stylish raincoats, handbags, catchy evening dresses.

The composition of a modern twill is a mixture of several types of fibers. The basis can be threads made of synthetics, cotton or wool and silk. Depending on their ratio, combination and properties, the material is divided into separate categories.

For example, if the material consists of 65% polyester and 35% cotton, it is commonly called polysatin. Combined fibers allow you to get a beautiful fabric with practical characteristics.

The twill is distinguished by visual gloss and a special twill weave of threads with a characteristic texture for the fabric - a diagonal hem. Sometimes untwisted knotted fibers are used to create the canvas, giving the finished fabric a special decorative effect.

Thick, but soft twill is not capricious in leaving and comfortable to wear. These are ideal qualities for home textiles and various clothes.

Production methods

The manufacturer takes twisted natural fibers as a basis, adding synthetic fibers to them in different percentages:

- cotton in half with polyester;

- 65% polyester to 35% cotton and vice versa;

- 75% wool to 25% cotton;

- 65% wool for 30% viscose plus 5% acrylic;

- wool 75% and 25% silk;

- 3% lurex to 97% pure wool and so on.

The addition of acrylic and polyester increases the strength of the fabric and reduces its weight, giving elasticity and preventing shrinkage.

Diagonal weaving of threads, or the so-called twill, with a ratio of weft to warp is equivalent to two to two. The warp thread, overlapping two transverse threads, moves in one direction, creating a decorative scar on the surface. Repetition of the main overlap creates an asymmetric rapport. The harder it is, the lower the density and the higher the diagonal hem. The thickness and density of the finished matter, its main characteristics depend on the combination of threads.

By production various dyes are used. They fit well on the fabric and do not fade over time. This is a very important indicator for finished products for any purpose. Most often, one-colored coloring is used.

Structure

Twill (twill) demonstrates a number of remarkable properties, the severity of which determines the number and type of fibers in its composition.

Textiles with unequal thickness and density, with a smooth or textured surface are most often produced from natural cotton fibers. Synthetic fibers such as elastane and polyester are added to improve practical performance. In finished matter, their percentage may vary. The characteristics of the finished fabric also depend on this: lightness or density, elasticity or stiffness, crease resistance or softness, multi-color or uniformity, smoothness or hairiness, susceptibility to delicate washing or dry cleaning.

In appearance, the twill resembles twill or satin due to the similarity of weaving threads. In the manufacture of twill, untwisted filaments of multicolored fibers are used. The thickness of the threads determines the practical application of the material.

If you treat the twill from the front or back side with a water-repellent composition, you can give the fabric new properties. The waterproof look of a twill is often used for tailoring workwear and military uniforms.

Advantages

The fabric demonstrates the undeniable advantages in any composition and therefore is ubiquitous in clothing and household items. Twill has many positive qualities.

- Strength and resistance to wear, standing out compared to satin or twill.

- Moderate density.

- Softness. The tactile sensations from touching the fabric are pleasant, and the products themselves are comfortable to wear.

- Ease of drapery.

- Good breathability. This quality is important for bedding and underwear.

- Dustproof. All dirt remains on the front side.

- Not susceptible to deformation, creases, stretching and shrinkage.

- Resistant to sunlight. Things do not burn out of the twill.

- The ability to dry quickly.Fungus and moth do not start on the fabric.

- Easy care (easy washing, drying, ironing and storage). The most unpretentiousness is noted in the cotton type of fabric.

- Twill items are outwardly attractive and neat.

disadvantages

Judging by most reviews and quality indicators, there are very few minuses for a twill. It should only be noted that:

- synthetics in the composition of the fabric may be contraindicated for allergy sufferers;

- the cost of a cotton type of fabric is high with insufficient elasticity.

The rest of the twill is not inferior to other high-quality fabrics, and in many ways even surpasses them.

This can be judged by its popularity among ordinary buyers, private seamstresses and fashion designers.

Varieties

Due to the fact that in the production of twill not only cotton, but also artificial fibers are used, as a result, several types of fabric are obtained. Each of them has its own properties and applications.

- Silk twill goes on tailoring expensive and high-quality clothes. To improve practical characteristics, elastane is added to the composition in a 3% ratio. Compared to a satin, a twill needs more silk, which is why its cost and sale price are higher.

- Elastic twill produced with the addition of viscose 20% at 80% polyester. Stretching properties can significantly expand the range of application of the material. He worked well in underwear: dresses, sweaters and the like.

- Twill cotton - very strong matter with a low content of elastane. The range of application is extensive and diverse.

- Twill twill - excellent lining matter. Not wrinkled, draped, not electrified. Keeps brightness and shape for a long period of wear.

- Woolen twill look light and thin with excellent warming and breathing properties. Used for warm blouses, suits and dresses. Actually in the autumn-winter season. Private seamstresses often sew plaids from this fabric, taking advantage of the fact that it looks attractive, does not wrinkle and maintains its presentation for a long time.

A typical 1/3 twill consists of cotton and 2/3 of polyester. The best quality is noted for the twill, which contains equal amounts of polyester and cotton fibers.

Cotton twill satin, elite silk (5% elastane), woolen (tweed type) and blended cotton, which is currently on sale in a wide assortment, are found on sale.

The most popular types of this unique fabric are worth considering in more detail.

Cotton

Modern twill satin is rapidly gaining popularity. When it is created, cotton and satin are used in a specific ratio in percent and symmetrical weave. The resulting material is distinguished by a lower density in comparison with ordinary satin with the preservation of external qualities, in which the differences are not determined “by eye”. The silky smoothness of the surface has a certain sheen, which attracts the attention of buyers. The main advantage of twill satin is the slight ability to crumple.

But in order to smooth out the folds on the matter, it will take minimal effort.

The material has excellent hygienic qualities, while it is durable even with very intensive use. Manufacturers value twill satin for color fastness. Saving housewives note the same quality. You can erase things without fear that the picture will fade or be erased. Matter can easily withstand hundreds of washing cycles, while preserving the richness of colors and attractive appearance.

Silk

Silk twill stretch consists of 98% cotton and 2% elastane. As a percentage, up to three units may be deflected towards one or another fiber. The addition of a small amount of elastane gives the product the ability to stretch and not wrinkle. This type of twill is widely used in light industry.

Silk with weaving threads on the diagonal is dense and "heavy."Such weaving requires more silk fibers. Therefore, a twill always comes out more expensive than a satin. The material gives the product the ability to keep its shape well. The fabric does not slip and is very pleasant to the touch. No wonder the creators of the elite Hermes brand noticed it to create their famous scarfs.

Mixed

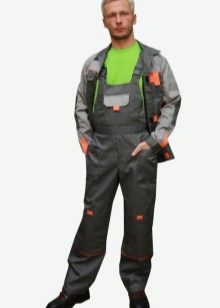

A blended twill type combining cotton (30-97%) and synthetics (most often polyester). A cloth of mixed fibers is used for sewing workwear, uniforms and suits. Such a material perfectly passes air through itself, allowing the skin to breathe, and high density makes it dustproof.

Application area

Initially, the diagonal weave material was made exclusively from sheep wool, without impurities. Rough and dense threads of dark colors created a heavy, dense, moisture-resistant fabric with an unusual pattern. Clothing was sewn from this material to government officials and businessmen, urban dandies and representatives of the bohemian environment. Innovations changed technology and touched the composition of the fabric. Cotton or silk began to be woven into the woolen thread, which made it possible to sew both classical costumes and hats, handbags, scarves and other accessories from the material.

In 2013, the concept of blending fabrics and the originality of weaving made twill the leader in the rating of the most purchased products manufactured by light industry.

Fashion designers have noticed an innovative mixed fabric to create stylish collections and clothes of an original cut. With success, the twill migrated to the furniture industry, becoming a ubiquitous participant in the creation of interiors. Upholstery, curtains, chair covers, tablecloths, napkins - this is only part of what can be sewn from varieties of twill. In addition to linen, home textiles and overalls, it can be found in outerwear. A more subtle type of twill is used in the production of summer dresses, all kinds of women's, men's suits.

The most popular area for applying twill fabric is sewing bed linen. It was appreciated and loved by consumers almost all over the world. The thing is its low creasing and quick drying, maintaining brightness after washing and the resistance of the fabric to high temperatures when ironing.

High-quality painting of the twill pleases the consumer with a long color fastness. And this characteristic is important for the corporate form, uniform and specialized clothing. At the same time, the twill meets the following requirements that apply to work clothes:

- hygienic;

- breathable;

- hygroscopic;

- dust-proof;

- comfortable;

- durable.

In addition, twill overalls, with their obvious practicality, added aesthetics and harmony to work clothes.

In general, the material is universal and finds the most extensive application, depending on the needs of the cutter or customer.

How is it different from other fabrics?

There is a surefire way to distinguish this light and pleasant tactile material with a low pile from other fabrics. You need to look at it from a certain angle. The diagonal pattern of the texture is noticeable very well.

It’s difficult to tactilely and visually distinguish a twill from a classic satin. The fabric has a satin-like sheen and gloss, but the twill counterpart is much cheaper.

Using the example of a membrane, we can compare the degree of breathability and steam removal of twill. A membrane is a film with the smallest pores, smaller in diameter than a water droplet, but larger than a water vapor molecule. Therefore, liquids will not be able to leak through the matter inside, but the fumes from the body freely penetrate outward due to different partial pressures from the outer and back fabric surfaces. As soon as a person begins to sweat, the membrane begins to "actively breathe" - remove vapors.

But in twill such abilities are not noted, therefore, with vigorous activity and high temperatures, the fabric is not the most suitable.

Most often, a twill is released one-colored, but sometimes a pattern is also applied to it, mainly camouflage.

When acquiring a twill, it is important to pay close attention to what is indicated in the composition. Since in modern types of tissues it varies significantly.

If you compare the twill with poplin, polycotton and others, there will be no difference in characteristics. The fabric is light, does not shrink after washing, almost does not crease, rarely requires ironing, and preserves the colorfulness of color shades. Like satin, the material can be washed in an automatic washing machine. After washing, the twill remains pleasant to the body and silky.

Care Rules

Although the twill is easy to operate, there are certain care recommendations that you must follow. Then the products will last a long time without spoiling.

- Twill satin is washed even at high temperatures using any detergents.

- The remaining types of fabric mixed type, wash at t no more than 40 degrees. Bleaching is not allowed. The use of detergents with an “aggressive” composition is prohibited.

- It is advisable to add a softener that prolongs the life of the fabric and preserves its structure and color.

- Do not dry the mixed twill in the sun.

- Ironing things is preferably wet.

If in doubt, it is easier to act as indicated on the label attached to the product by the manufacturer. Only then will a thing benefit and last a long time, bringing tactile and aesthetic pleasure.

About twill bedding, see the next video.