In the period of rains and slush it is rather difficult to keep shoes dry. And this is a question not only of comfort, but also of health. To solve it, you can make a shoe dryer. Its use will help the shoe to always be in good condition.

Tools and materials

Due to the fact that the shoe dryer is made by hand, its cost will be much lower. Hence, you need to choose materials from improvised means. This can be the remains of pipes, strong wire, construction tape, terminals, heating elements. Some materials and tools will have to be purchased, but in general, a home-made shoe dryer should be inexpensive, but functional.

Dryer manufacturing options

Depending on the materials, complexity and functioning options, different types of shoe dryers can be made. We suggest you familiarize yourself with the following solutions.

Flexible

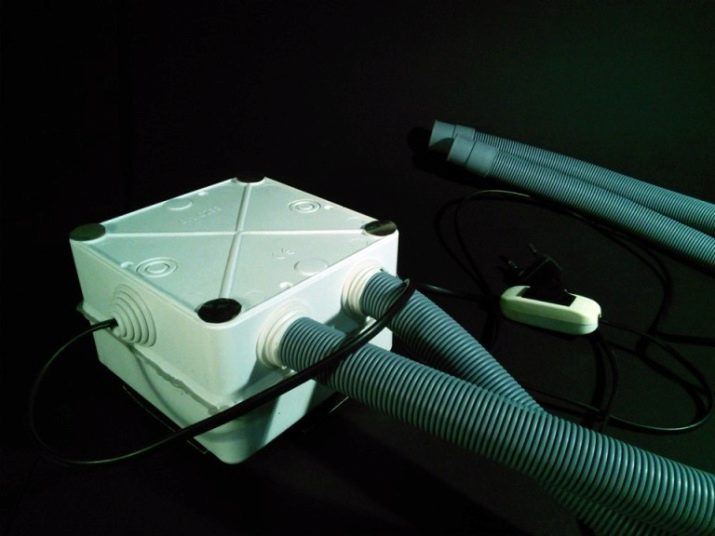

To make this dryer, you will need a corrugated pipe (1 m), a box and a hairdryer, a computer cooler or a small fan.

The principle of this device is that the air from one hole in the pipe is distributed in 2 pieces of shoes that are located at the other ends of the structure.

- First you need to construct a boxwhere the fan will be located. You can buy ready-made or make it yourself.

- After that you need to put a fan in it and make holes for pipes through which air will pass. If the blades do not fit, they can be trimmed.

- Corrugated pipe must be divided into 2 parts 50 cm and insert into the holes.

- The fan in the box must be connected to the network using a wire with a plug.You can also use the power supply with an on and off button.

- After all the parts are connected, check all openings so that no air escapes from them. Eliminate gaps can be rubber pads or electrical tape.

Such a shoe dryer does not take up much space and is easy to carry out. If your shoes are wet, it will take about 5 hours to dry them. If you need to ventilate or slightly dry your shoes, you can leave the dryer to work for 2-3 hours.

It does not damage the outer surface of the shoe, as it dries exclusively from the inside.

Electric

This type of shoe dryer may seem difficult to manufacture, but it is not, here you only need to have an initial level of knowledge in connecting wires. To make the device, you need a heat pipe or a heating cable, which is often used in a heated floor system, a wire with a plug, two wires for connection, an electrical tape and a knife. Some materials may have to be purchased at a hardware store or in the market.

- First you need to cut off 2 pieces of thermal conduit 50 cm long each and strip them on one side. Then twist in a circle so that the end with uninsulated ends was separate, and secure with electrical tape.

- Also, 2 wires must be connected to the wire with the plugthat will be attached to the heat pipes.

- It remains only to connect the design in this order: wire with plug - wires - thermal conduit. All connections must be wrapped with electrical tape so that there is no access to the bare terminals.

Such a dryer works from a 220 V outlet.

From plastic pipes

The dryer for shoes made of plastic pipes works from the heating system in the house, so in this case you do not need to use electricity. Its principle is that hot water is driven into the pipes, the temperature from which dries the shoes. Polypropylene pipes are used because the thermal conductivity of plastic is higher than that of metal, which means that more heat will be generated.

To make such a dryer, you will need plastic pipes, angles, tees, crosses, Mayevsky taps, fastenings to the floor and wall.

- The number and dimensions of parts depend on the dimensions of your drying, so it is important to calculate everything correctly before assembling.

- The most important step is to assemble the bottom shelf. It should be flat and clearly horizontal. Next, you need to add as many shelves as you need.

- Each tier must be secured with a soldering iron or other method of fastening. This can only be done after you have made sure that the structure is even.

- On the upper shelf, it is worth attaching Maevsky cranes to let out air pressure stagnant in the pipes.

- Next, you need to attach the dryer to the wall, making sure that the shelves hold firmly.

- After this, run the water pressure into the pipes and check all joints for leaks. If everything is in order, then you can start using it.

In order to improve the drying work, you can perform several actions that will help it to function better.

- To prevent the sole of the shoe from deteriorating from high temperature, use wooden coasters that will serve as a barrier between the hot pipe and the shoe.

- To prevent water and dirt from draining from the shoes to the floor, you can put a container on the floor into which this water will collect. But it’s best to wipe and clean the shoes from dirt before putting them on the dryer.

- Also check regularly that water does not leak from the pipes. To do this, you can attach a tap to drain the water.

There is another way to make shoe dryers out of plastic pipes. The product will be smaller in size, and it is attached to the battery.

How to do:

- First you need to make a shelf from PVC pipes and make fasteners in the form of loops or hooks, with which the shelf will be hung on the battery;

- tighten all connections carefully so that the dryer is solid.

Shoes on such a dryer can be placed in any position.

The main thing is that it does not touch the hot battery, otherwise the material may be damaged.

From the fans

Such a shoe dryer is suitable for both low boots and high boots.

To make it, you will need two fans from the computer, a power supply or a wire with a plug, connecting wires and pipes made of plastic.

- If you use a wire with a plug for the dryer to work from an outlet, then you need to connect it to two fans. And if you chose a power supply, then you need to connect to it. This is easiest to do with the help of connecting wires for which the ends need to be cleaned in advance.

- So that the dryer can be used to dry high boots or ski boots, plastic pipes must be attached to the fans. Then the air will be directed to the very bottom of the shoe. It is there that she gets wet.

Precautions

Experts highlight several important rules that should not be neglected in the manufacture of shoe dryers.

- If you work with wires and use electricity, make sure your hands are completely dry.

- Use rubber gloves when working.

- Do not check if there is current in the network with your bare hands.

- Do not insert plugged and heated electric dryers into shoes. Insert the appliance first, and only then turn on the shoe to warm up and dry gradually.

- Do not leave electric dryers plugged in for extended periods without supervision.

- Do not lay the included electric dryers on the floor or on other surfaces that are not suitable for this. Use ceramic or metal stands.

A workshop on the manufacture of an electric shoe dryer is further in the video.