Singer sewing machine of the late XIX and early XX centuries still causes great interest among many consumers. Most antique products are still usable. Legendary antiques perfectly fit into the interior of any apartment.

History

The creator of the world-famous sewing machine is Isaac Singer. Since 1850, he began to live in New York, where he met with a local manufacturer of sewing machines. The designer dedicated Singer to the principle of his own sewing machine. The product was characterized by circular movement of the needle. The thread was constantly tangled in a vertically located shuttle.

Isaac Singer was impressed by the design. Within 10 days, he improved it. Singer invented the mechanism for moving the needle up and down. All sewing devices still have this way of moving the needle. The inventor introduced 4 important innovations:

- the horizontal location of the shuttle led to the fact that the thread stopped tangling;

- the use of a foot drive and a presser foot created additional comfort for the seamstress;

- a leg-holder and a built-in board such as a table contributed to the convenient placement of fabric for sewing;

- All products began to be supplied with operating instructions.

These improvements have greatly increased labor productivity. The designer has acquired a patent for his invention. In addition, it was he who invented the repair of the house by replacing individual parts. Prior to this, broken products were sent to the factory to fix the breakage or discarded. Singer cars quickly became in great demand all over the world.

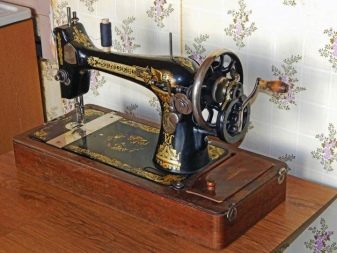

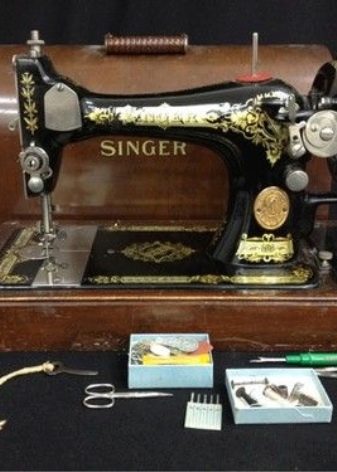

At the end of the 19th and the beginning of the 20th centuries, Singer Corporation produced many models with various names.Sewing machines were produced in different countries under the license of Singer, since in those days the company was the sole holder of a patent for the right to manufacture such products. The construction of the Russian plant for the production of Singer brand sewing machines was carried out in the city of Podolsk near Moscow from 1900 to 1902. Subsequently, for almost a century, products were produced under this brand.

The year of manufacture of Singer sewing accessories can be found by serial number. Until the beginning of the 20th century, it consisted of only numbers, for example, in 1871, products were issued with numbers from 611,000 to 913.999; in 1899 - from 15.811.500 to 16.831.099. After 1904, a letter was added to the numbers. So, modifications of 1904 can be determined by serial numbers from B-1 to B-791.500, 1935 - from Y-9.633.847 to Y-9.999.999. The country of manufacture was encrypted in letters. So, the letter “A” meant that the model was produced in Podolsk (Russia), “B” in the city of Elizabeth (New Jersey, USA), “Y” in Scotland.

What is valuable in cars?

Singer sewing machines manufactured in the late 19th and early 20th centuries are of antique value. The older the product, the more expensive it is. It is believed that precious metals were used in the manufacture of sewing machines from 1886 to 1930: gold, silver, platinum, palladium. You can check their presence with a magnet. It is necessary to conduct them on the metal frame of the product. Precious metals are not attracted to the magnet.

Some consider the use of precious metals in the manufacture of sewing appliances to be a myth. Existing antiques have traces of heavy use, and precious metals are known for their softness and fragility. Products would not withstand such a heavy load.

Singer sewing devices are appreciated for their simplicity and ease of use. They cope with very complicated tailoring. Most of all they are valued for reliability, durability, high quality in work. They are not inferior to some modern models. Antique products work without the use of electricity, but, according to some consumers, they can cope well with leather products, leaving even stitches on very complex types of material. Any dense fabric is subject to them.

The old Singer sewing machine has exhausted its resource as a production tool. In the modern world, rarity is most often used for interior decoration in retro style.

Model Overview

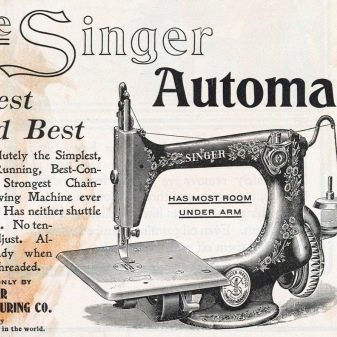

Singer household appliances at the end of the 19th and the beginning of the 20th centuries had a standard look. All sewing units of the first issues were equipped with an old-fashioned shuttle. The shuttle device was not round, as in modern versions, but had an elongated appearance. A long bobbin with thread was inserted into it. Such a machine made it possible to sew without passes. The needle looped twice to grip the nose.

The production of sewing accessories with a swinging shuttle was also established. The device had a shuttle stroke. Some modifications were equipped with the original bobbin winding mechanism. There are many types of antique Singer aggregates with horizontal shuttle fixtures.

Modifications were distinguished by the presence of one or two lines. Some of the products had only one straight line. Other sewing household units could also perform a zigzag line.

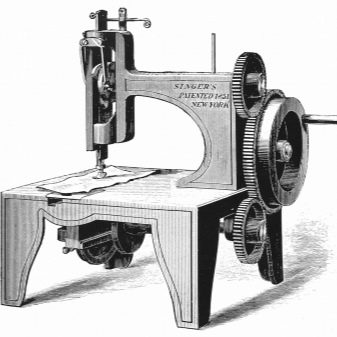

Sewing accessories were equipped with a motor with manual or foot drive. The flywheel of Singer products was massive. Machines with a manual drive had 2 gears bolted to the body with large bushings. If necessary, the sleeve-screws can be unscrewed and tightened again.

On some models, the foot pedal with a wheel drive replaces the inconvenient hand lever. By pressing a foot on a special pedal, a person can easily operate a household appliance. Designs are constantly being improved. After some time appeared modifications equipped with an electric drive.

At the end of the 19th century, the workshop of the Russian merchant Popov began the production of sewing units under the Singer brand. The features of these sewing devices include shuttle movement along the typewriter. The thread was pulled primitively due to the square cross section of the needle holder. The thread passed through the holes in the shuttle; its tension was poorly regulated.

Another disadvantage of the design is the low grinding speed.

How to setup?

If the antique settings fail, they must be adjusted correctly. You can adjust yourself. Failure caused by skipping stitches indicates that the needle is not installed correctly. Slippage of stitches in the stitch is observed when the needle is too high with respect to the hook nose. It can also be caused when working with very dense material. The coarser the fabric, the stronger the foot should be pressed. When setting up the Singer sewing machine, it is recommended that the needle be lowered. First you need to remove the foot, needle plate and front cover. Then all parts and the compartment must be cleaned of dirt. Carefully insert the bobbin into the bobbin case, then adjust it with the screw.

With the needle plate removed, the flywheel is rotated, the shuttle nose is checked for compliance with the tip of the needle and the groove. It should be just above the eye of the needle. It is very important to perfectly position the needle and correctly thread the thread from the side of the elongated recess. Old modifications of the Singer brand include finding the saw flask on the right side. The thread must be inserted into the eye on the left. The distance between the hook nose and the needle must be carefully verified.

The shuttle spout must fall exactly into the loop.

If the sewing device has not been used for a long time, it must be carefully treated with special machine oil. For this, there is an opening on the device case. Some important components from below also need lubrication. To do this, turn the machine on its side and grease all the metal parts involved in the friction. Oil can be poured into a medical syringe and instilled into existing openings. For penetration of the substance into all hard-to-reach places, it is necessary to drive the device at a low speed with a raised foot without an inserted thread. Excess grease is cleaned with a cloth.

When the flywheel is jammed, it is recommended to remove it and, together with the shaft, treat it with oil mixed with kerosene in a 1: 1 ratio. To avoid damage to the rarity, make sure that the operation is carried out strictly according to the instructions. During sewing Do not pull the fabric, otherwise you may damage the shuttle spout. The flywheel is allowed to rotate only in its direction.

It is not allowed to lower the needle with the thread threaded onto the bare plate. It is forbidden to sew after raising the foot up.

In the next video, you will find the restoration of an old Singer sewing machine.