Today, a wide variety of sewing machines are on the market. Moreover, they differ not only in functionality, but also in appearance, manufacturer and some other characteristics.

The popular brand “Seagull” is considered a popular domestic manufacturer of sewing machines. It has a rather long history of existence, and therefore has already managed to win the love and trust of consumers (and not only in our country, but abroad).

What are the features of the devices of the company "Seagull"? How to configure and adjust the machine? What problems may arise during the operation of the device? Which models are considered the best? You will find answers to these and some other questions in our article.

Brand Information

Chayka brand sewing machines have a rather long and interesting history. So, The factory where they began to be produced was established in 1900.. At that time, the production of units was carried out through the latest technologies and scientific developments.

Thus, we can conclude that the Chayka brand is a fairly old and tested time.

Large-scale production of sewing machines under the Chayka trademark began in 1914. At that time, the plant produced more than 600,000 units per year. This amount was due to the great demand for devices: cars were popular not only among domestic consumers, but also abroad (for example, in Japan and China).

After the October Revolution, there was a decline in the production of sewing devices. but after the Great Patriotic War in the USSR, the demand for cars increased again, accordingly, their production intensified.

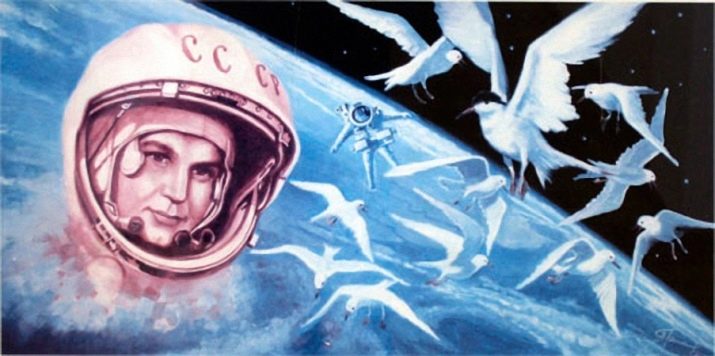

Generally speaking, the sewing machine received its name for a reason. The device was named after the first Soviet woman-cosmonaut who had a similar callsign.

The peak of sewing machine production “Seagull” occurred in the 90s of the twentieth century. Despite the fact that during this period a large amount of equipment was imported into our country from abroad, many domestic needlewomen still preferred Soviet products.

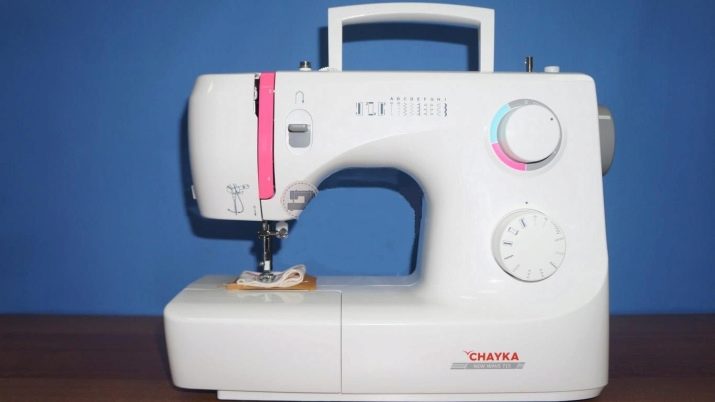

To date Chayka brand sewing machines are widely represented in the domestic market. As at the very beginning of their production, only experienced professionals are engaged in the manufacture of devices, who rely on the latest developments and technologies in their work.

In addition, the manufacturer offers customers a fairly wide range of products - respectively, each needlewoman will find a device to her taste.

It is also planned to expand the product lines: in the future, under the brand name, in addition to machines, other devices will be produced (in particular, ironing boards).

Device Features

Among the main features of the devices of the company "Seagull" it is customary to distinguish such characteristics:

- quality;

- reliability;

- durability;

- ease of use;

- modern design.

All parts of the Chaika sewing machines (pedal, electric drive, presser foot, etc.) are made of high-quality materials with a long service life.

At the same time, despite the rather complicated internal structure, the machine is quite simple to use even for beginners, and in case of questions, each user should familiarize themselves with the instruction manual.

It is worth noting that the fact that regardless of the fact that the brand itself is quite old, it complies with all modern trends. That is why the unit of the company "Seagull" will comply with all the latest developments not only in terms of functional component, but also in appearance.

Besides, Of particular interest is the fact that today in the market you can find both old models of devices, as well as newer and more modern ones.. The thing is that even despite the fact that functionally and technically old models (for example, 132 and 134) are already outdated, they are still able to work. This is possible thanks to the responsible approach of the manufacturer to their product.

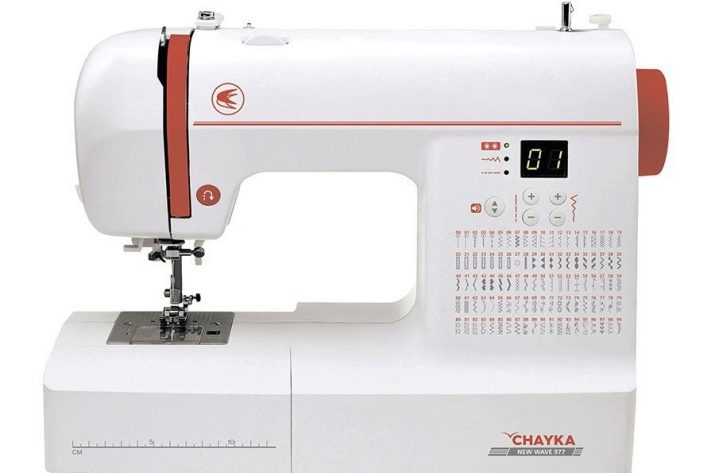

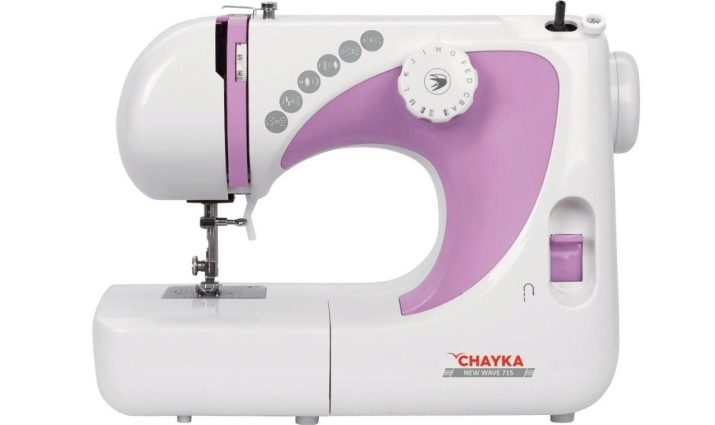

On the other hand, if you are looking for a modern machine that meets all the requirements and is made taking into account the latest developments, then you should pay attention to the latest models of "Seagulls". Such machines not only have a wide range of useful functions, but also have an aesthetically attractive appearance.

The lineup

The range of sewing machines of the company "Seagull" includes a variety of device models. Here you can find electric, manual, foot and other units. Today in our material we will consider the most common of them.

Seagull 134

"Seagull 134" is a model of a sewing machine, which in its functional, technical and external characteristics is similar to version 132. With the help of this unit you can make straight and zigzag lines. In addition, there is a reverse move.

"Seagull 143"

The machine is intended solely for domestic purposes. With it, you can process flax, synthetics, silk, etc. For this, several lines are provided. The length and width of the stitch are adjustable. During the operation of the apparatus, you can use sewing cotton and natural silk threads.

"Seagull 143" is presented in several delivery options:

- in a table with a foot drive;

- on a stand and in a case with an electric drive;

- with electric and foot drive in the table;

- with electric drive in the table;

- with manual drive on the stand and in the case;

- with manual drive in the table.

In addition to the main device, the kit includes a set of sewing accessories in a box, instructions for use, warranty card.

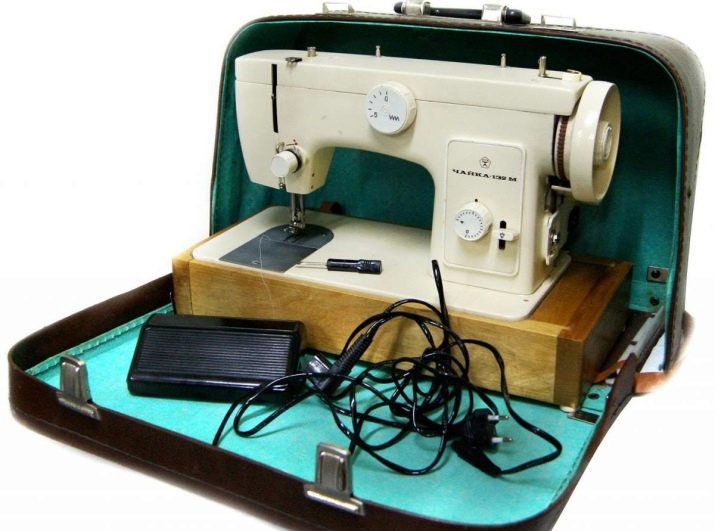

The Seagull 132M

This device is the first electromechanical sewing machine from the manufacturer "Seagull". The model was in production from 1980 to 1992.

It is believed that the "Seagull 132M" can cope with a variety of fabrics (including thick fur).

As for the technical characteristics of the device, it is important to note that the manufacturer has provided 4 types of stitches and 23 sewing operations. The maximum length and width of the stitch are 4 and 5 mm, respectively.

The device has a pretty impressive weight of 13.5 kg. That is why it is quite difficult to cope with it (especially with regard to its transportation).

Seagull 134A

This model belongs to the category of electromechanical machines. At the same time, it is well suited for home use, and even a beginner needlewoman can cope with it.

The outer casing of the machine is made in white with small colored splashes. The device panel contains step-by-step diagrams necessary for starting operation. For your convenience, the manufacturer also provided a “Reverse” button, by clicking on which you can fix at the end of the line or cut the thread.

"Seagull 134A" is programmed to produce 10 sewing operations (including zigzag, straight line, semiautomatic loop, etc.). In this case, there is a function for adjusting the length and width of the stitch.

The device was manufactured in Vietnam. The machine weighs about 6 kilograms.

The models described above are older versions of The Seagull. Today, there are more modern and advanced models with advanced features and attractive appearance. These include models 110, 210, 325A, 715, 735, etc.

Setting and adjustment

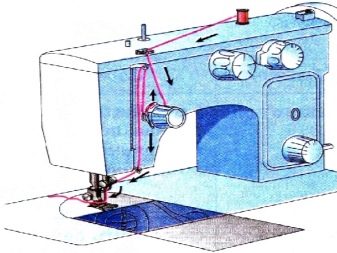

- First of all, the thread take-up should be set to its highest position. This procedure can be carried out using the flywheel.

- Then raise the foot.

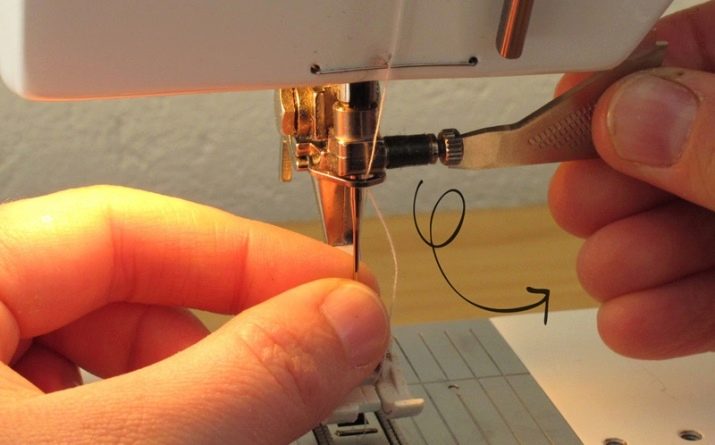

- Now you need to insert the needle into the needle holder. Make sure that it is fully seated.

- At this stage of adjustment, it is necessary to pull out the spool pin and strengthen the spool of thread.

- Next, thread the thread. Moreover, refueling should take place in a strictly defined sequence. So, first you need to do this from a bobbin or reel through a thread guide. After that, between the regulator washers, check the thread tension. Next, we thread the thread into the thread guide on the machine head and into the thread guide on the needle holder. Next, we thread the thread into the eye of the needle.

- The next stage is the opening of the slide plate.

- We take out the bobbin case and remove the bobbin itself.

- Loosen the friction screw and wind several screws onto the bobbin. Next, install it on the spindle of the winder and press. We wind the bobbin and insert it into the cap.

- Now we thread the thread into the slot and under the tension spring.

- We insert the bobbin case on the axis of the hook and wrap the friction screw.

- Now you can lower the needle and raise it to the upper position. This action is performed using the flywheel. As a result, you should grab the shuttle thread.

- We remove the shuttle thread and thread both threads under the foot.

- Depending on the material with which you will work, select the appropriate mode.

Thus, after the end of adjustment and adjustment, your machine is ready for full work.

Terms of Use

Before you start working directly with the device, it is important to carefully study all the rules for its operation. For this It is necessary to read the manufacturer’s instructions, which is an integral part of the standard set of any model of the sewing machine “The Seagull”.

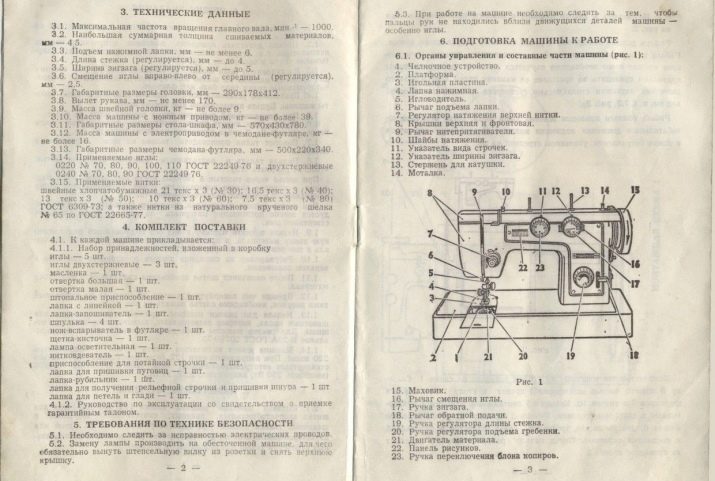

It should be noted immediately that The application guide consists of several sections, each of which is devoted to a separate topic. and explains how to use the device correctly in a particular case.

First of all, it is necessary to pay attention to the stated safety requirements.

Before you turn on the machine, you should make sure of its external integrity (especially with regard to wires and power plugs).

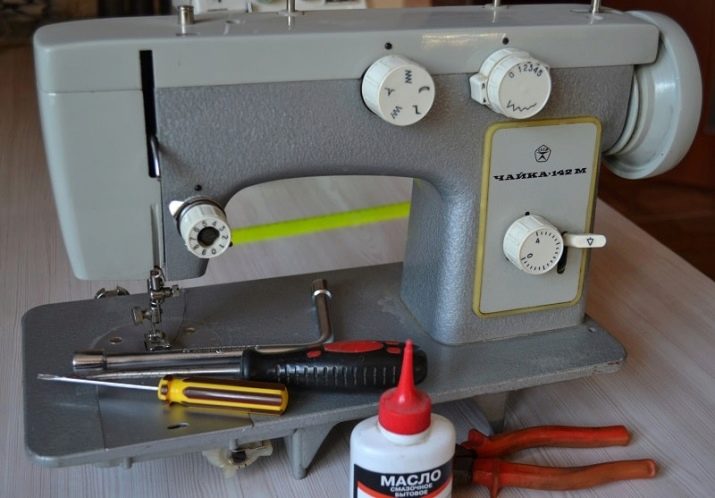

In the General Requirements section, you will find the rules for installing the needle and handwheel. The need for regular lubrication is also noted here: the machine must be lubricated using specially designed oil (for example, I-20A GOST 20799-88 can be used).

The instruction manual also includes the following sections:

- "The purpose of the machine" - the device is allowed to be used only in those cases and for those purposes that were originally provided for by the manufacturer;

- "Technical details" - here all the technical indicators of the device are painted in detail;

- "Contents of delivery" - during the acquisition process, it is important to check the availability of all the elements indicated in this paragraph;

- “Recommendations for getting a quality line” - the section describes the features of working with the device (this section will be especially useful for beginners);

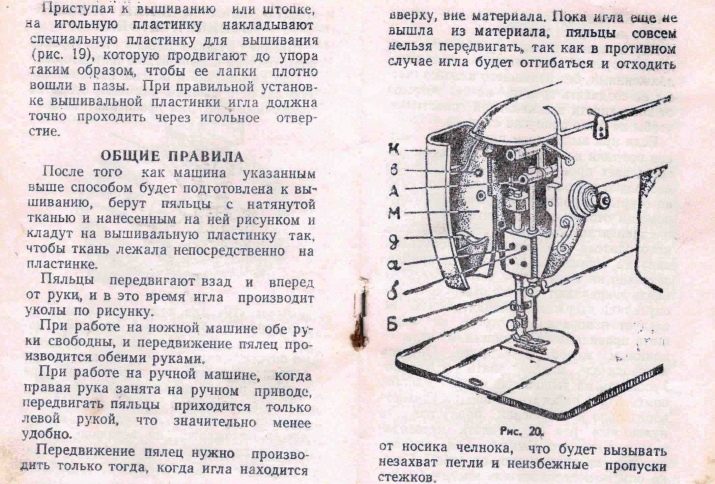

- "Controls and components of the machine" - This chapter usually contains a visual block diagram;

- "A set of accessories" with drawings;

- “Types of operations” with diagrams and brief explanations;

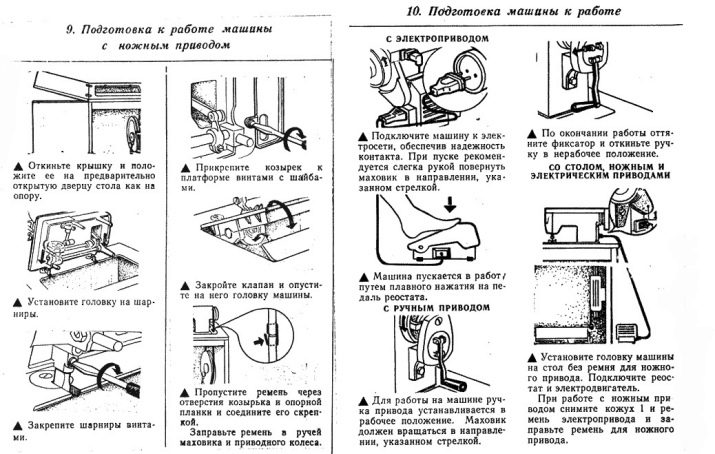

- "Preparing to work with the foot drive" with brief but concise instructions;

- "Preparing the machine for work" - the section describes actions that are mandatory;

- "Preparing the machine for sewing" - a section with subsections and explanatory diagrams;

- “Lubricating the machine” - describes in detail the rules for lubrication;

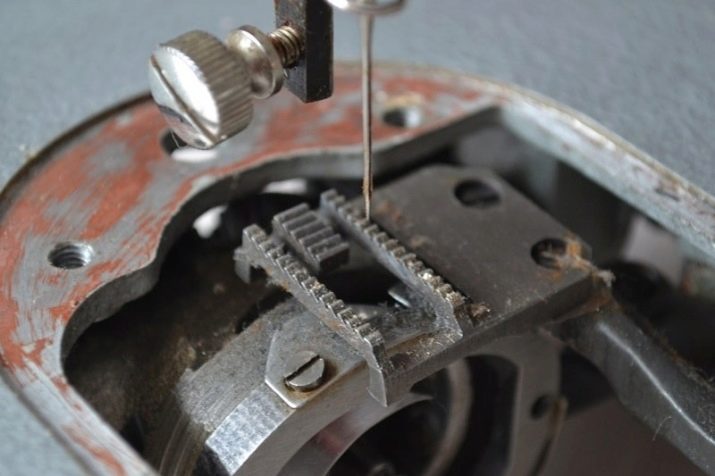

- “Cleaning the shuttle device” - the section includes the rules for servicing the machine;

- “Possible malfunctions and methods for their elimination” - the chapter will be useful in case of breakdowns.

Thus, the manufacturer provides the user with a fairly detailed instruction manual, the rules and principles of which should be strictly observed. If you have any questions or difficulties, you can also contact the seller-consultant in the store.

It is important to keep in mind that some points in the instructions may vary depending on the specific model of device.

Major malfunctions and their elimination

Despite the fact that sewing machines “The Seagull” are quite reliable devices that are made of high-quality materials and are intended for long-term use, the manufacturer does not exclude the occurrence of malfunctions and breakdowns.

Possible malfunctions and methods for their elimination are described in the operating instructions for the device. Consider the main ones.

Needle breaking

Most often, this problem occurs due to the incorrect position of the presser foot, the wrong choice of a specific needle (or if the needle itself is poor-quality), as well as in cases where a novice works with a sewing machine.

To fix this problem is quite simple, and the method of elimination will depend on the cause of the breakdown.

So, the manufacturer recommends changing the needle to a more suitable one or checking the head screw of the presser foot (it must be fixed so that the foot is in the correct position relative to the needle).

The upper thread breaks

If this problem occurs, first of all you need to make sure that you have threaded the thread correctly. In the process of performing this action, you must strictly follow the instructions. Also, a break can occur due to the thread being too tight (in this case, the tension must be loosened). Another reason is the poor quality of the thread or the needle itself.

The bottom thread breaks

Most often, the lower thread breaks due to the fact that it was originally improperly threaded in the bobbin case.

Skip Skips

This malfunction is one of the most common. It arises from the use of polished threads, an improperly installed or improper needle. If you eliminate these problems, the sewing process will take place according to all the rules.

Difficulties with the promotion of material

In this case, you need to check the tooth lift and material clamp. Most likely, the reason lies in this.

To fix the problem, it is recommended to adjust the tooth lift, remove the screws, remove the cover and turn the foot bar screw clockwise.

Heavy move

If you notice that the machine works with a lot of resistance, then you should clean the shuttle stroke from scraps and a scrap of thread, lubricate the machine with oil, clean the area under the needle plate or stretch the belt.

In addition to the problems described above, problems like knocking on the footrest, belt slippage or lack of lighting can occur. They are quite rare, but in case of their occurrence, it is important to carefully study the operating instructions.

Anyway, In no case should you neglect the repair of the sewing machine (especially if it sews the other way around or the parts become worthless). If there is a sufficient amount of technical knowledge, and also in the case of strict adherence to the instructions, repair work can be carried out independently. In other cases, it is recommended to consult a specialist.

The desire of the manufacturer to grow, develop and constantly improve the quality of its products has led to the fact that sewing machines "Seagull" are still competitive and are in demand in the market.

The description and functionality of the new 750 sewing machine model "The Seagull" can be found in the next video.