In the jewelry industry, specialists often use various methods to change the appearance and physical characteristics of products. Silver and gold are used not only in the manufacture of jewelry, but also for processing products from various metals. Along with gilding, the silvering process is also in demand, let us consider in more detail its purpose and methods.

What it is?

Silvering is a special process during which objects are coated with a thin layer of light metal. Processing is made of items made of alloys of various metals. This option is in demand by both beginners and experienced jewelers. The essence of silvering is to enhance the decorative and physical properties of the product.

Covering with an additional layer significantly improves the appearance of the object, the shine and radiance return, defects are overlapped, the decoration acquires an attractive shade. A it is also worth paying attention to the passivation of the metal - this is the process during which the metal surface goes into a passive state. As a result of such changes, the metal becomes immune to corrosion and other negative environmental influences.

Processing with precious material can be done independently by preparing special tools and ingredients (chemical compounds, silver and other substances).

Appointment

As already noted, silvering is performed not only in laboratory, but also at home. The main thing is a step-by-step process and compliance with safety standards. The main purpose of silvering is to improve aesthetic qualities and protect the product from damage. In most cases, the following metals are coated with a thin layer of silver:

- brass;

- copper;

- aluminum;

- steel;

- nickel;

- silver (antique jewelry fades over time and takes on a yellow hue, with the help of processing they will again begin to please the eye).

The practice of processing not only jewelry, but also cutlery is widespread. The price of some sets reaches several million rubles. To preserve the presentation, it is recommended to periodically cover objects with a thin layer of light metal.

The silvering process is subject to materials such as:

- ceramics;

- plastic and plastic;

- iron;

- glass (we are talking not only about the processing of mirrors, but also the bearing of decorative details on a glass surface).

If everything is clear with the visual purpose of the procedure, it is worth considering the practical side in more detail. Silver has the following characteristics:

- electrical conductor;

- high resistance to oxidation and corrosion;

- excellent reflectivity and thermal conductivity.

Silvering Methods

There are many options for processing products by applying a thin layer of silver on them. This service is especially popular in jewelry workshops, where it is also called oxidation. This procedure is subjected to jewelry as well as products from other metals. In addition to the chemical elements necessary for the preparation of solutions and pastes, the following should be prepared:

- tight gloves;

- work clothes;

- rags in the amount of several pieces;

- a fan (if there is not enough ventilation in the room where silvering will be carried out);

- spray gun - with blunt spray guns it is easier to clean hard-to-reach areas on various products and jewelry.

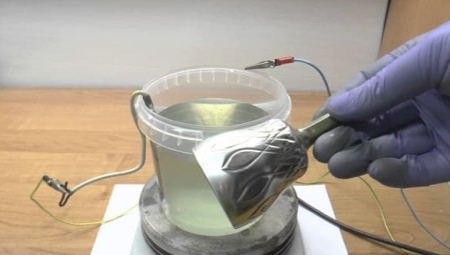

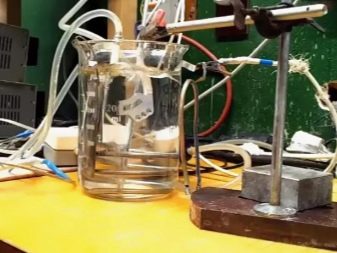

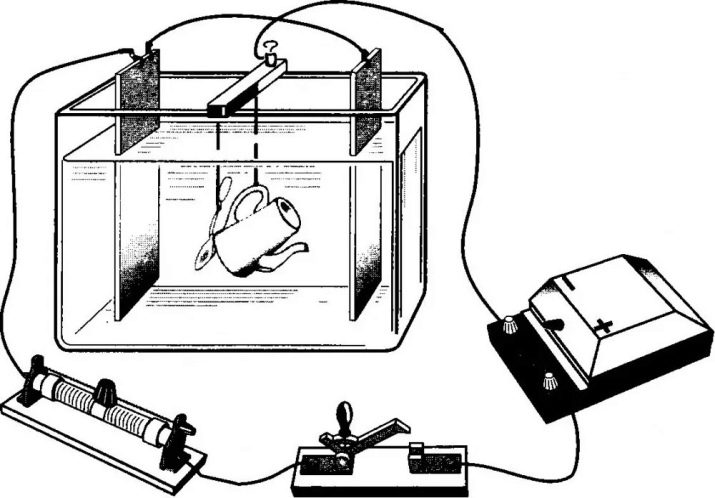

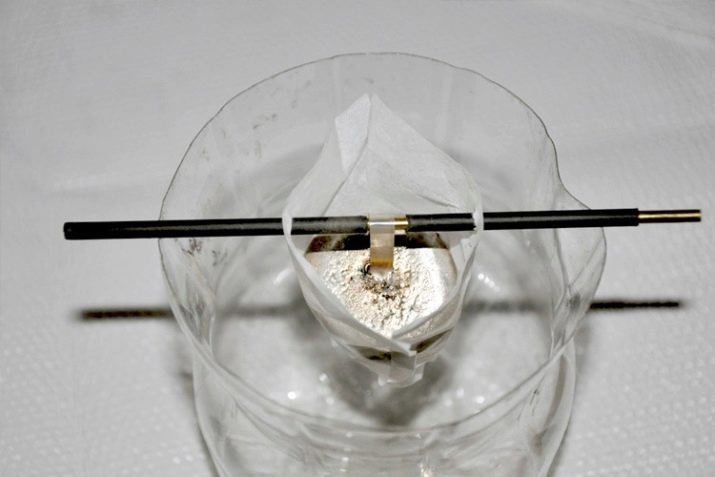

Galvanic

This method provides an electrochemical effect on the product or surface to be treated. The main feature of this method is that the precious metal molecules settle in an uneven layer. As a result, a crystal pattern is obtained on objects. The transfer is performed by closing an electrical circuit.

To do the work you will need the following:

- a container into which the workpiece can be loaded; it should be plastic or glass;

- electrolyte (for filling the tank);

- during work the product needs fixing, therefore special holders are necessary;

- current source;

- silver used for application.

The processing process is as follows:

- items for processing are connected to a negative charge;

- to a positive charge you need to connect an object, the chemical elements from which will pass to another object;

- under the influence of an electric current, silver molecules begin to settle on the surface of the workpiece, resulting in a reliable protective layer with a pleasant sheen.

Chemical

In this case, you need to prepare a solution of special reagents. When interacting with other metals, they will form white precious metal molecules. They will serve as raw materials for additional coverage. To carry out the work, antichlorine in the amount of 1 liter is required. And also it is known under the name - sodium thiosulfate. Do not do without the following components:

- ammonia (ammonia solution) - 5-6 drops;

- formalin - an approximate volume of 6 to 10 drops.

Silvering at home is performed as follows:

- alcohol is poured into the main component, observing the indicated proportions;

- the item selected for processing properly prepares; it must be thoroughly cleaned by placing in a soda solution and boiling;

- rinse with water after;

- place the product in a liquid from chemicals, leave for 2 hours;

- after time, the item is rinsed and left to dry.

Using pasta

To prepare the necessary substance at home, you need to prepare special chemicals.The treatment option is selected depending on the metal to be coated with silver. Consider the method using copper as an example. The list of necessary reagents:

- distilled water;

- potassium chloride (salt) - 8 grams;

- tartar - 8 grams;

- silver chloride - 6 grams.

The procedure is performed as follows:

- used alloy must be cleaned of rust, if any;

- the chemicals are ground and mixed until a substance is obtained in the form of a gel or paste;

- the whole copper object is coated with the resulting compounds; a rag (rag) is used for work;

- the paste is kept on the surface until a silver layer is formed, and then there is washing and polishing.

Note: in order to consolidate and strengthen the result, you can use a brightener - this is a composition that can be bought in a specialized store.

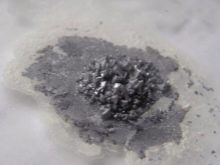

Nitrate coating

In this case, you will need to purchase silver nitrate, which is also called a lapis pencil. This is a difficult silvering method, but it forms a reliable and durable coating on the surface. To prepare the solution, you need the following components:

- nitrate - 2 grams;

- water - 300 milliliters.

Hydrochloric acid is gradually mixed into the resulting composition. Together, you can use a solution of table salt based on water (10%). Preparation of the solution must be performed until the sediment - silver chloride - becomes noticeable at the bottom of the container. The resulting substance should be carefully collected and washed with plenty of clean water.

Pieces of silver falling to the bottom in the form of flakes are thoroughly mixed with a liquid that consists of sodium hyposulfite (20 grams) and pure water (100 milliliters). The finished mixture is filtered and mixed with chalk crumbs or regular tooth powder. A solution is prepared until a substance resembling sour cream is obtained. The resulting composition is applied to the product and left for a certain time until a silver film appears on the surface.

Heat

Another option for processing the product at home is by heating. To work, you need a special solution in which the item is immersed. To prepare the mixture yourself, you will need the following components:

- table salt - 600 grams;

- silver chloride - 100 grams;

- tartar (this element is also indicated under the name - potassium bitartrate) in the amount of 600 grams.

Having mixed all of the above elements, you get a powder that retains its properties for many days.

It must be stored in a dark glass container. To prepare the solution, you will need water. For 5 liters of liquid, use no more than three tablespoons of the finished dry powder. The composition is brought to a boil, after which the product is lowered into the liquid and boiled for half an hour.

In the process, a stable plaque is formed. To get rid of it, you can prepare the following mixture:

- pure water - 5 liters;

- acetic-lead salt - 100 grams;

- antichlor (also known as sodium sulfate and hyposulfite) - 300 grams.

The solution is heated to a temperature of about + 80 ° C. An object is immersed in it for 25 minutes. After processing, an attractive shine appears on the subject.

Additional recommendations

To determine which method is best for each material, it is recommended that you conduct a trial treatment and compare the results. When working at home do not forget about safety, especially when using hazardous chemicals.

If you are going to perform silvering on a professional level, consider purchasing mini-equipment. This will greatly simplify and protect the work, and its compact size will allow you to place it at home.

Using chemical reagents and knowing the process of doing the work, amalgamation can be performed in non-industrial conditions. This is the process of extracting metals from ore. However, this method involves the use of mercury, which makes the procedure especially dangerous.

Precautions

The following tips should be followed:

- chemicals that enter into the reaction can be harmful to health and well-being, therefore, the room for the procedure must be thoroughly ventilated;

- make sure that no strangers approach the workplace, especially for small children and pets;

- the resulting waste should be disposed of safely, depending on its composition;

- be sure to use gloves, respirators and special glasses, and it is recommended to wear protective clothing;

- after silvering is complete, clean tools, work clothes, and protective equipment.

About silvering methods see in the next video.