The noble brilliance of silver fades and blackens over time. Thus, the oxidation of copper in the metal alloy is manifested. Therefore, the lower the product, the more pronounced the patina (oxide film) on its surface. The oxidation is caused by the interaction of chemical elements and sulfur compounds secreted by human sweat. For this reason, it is recommended to remove silver during sports activities. But this does not apply to products coated with rhodium.

What it is?

Rhodium is necessary to protect the metal from mechanical damage and oxidation. Trying to understand the intricacies of jewelry, it is important to understand that precious metal products are coated with rhodium. Radium is a completely different chemical element, which is a decay product of uranium and is considered radioactive. In a small amount, it is contained in uranium ore.

This metal is deadly and is not intended to work with jewelry.

But rhodium is absolutely safe and does not cause allergies, for which it is widely used as a protective layer for metal products that are worn on the body. The cost of rhodium is several times higher than the price of gold, so jewelry is not made from rhodium. Due to their incredible hardness, metal is mainly used for coating precious products.

They are mainly covered with 925 silver and, less commonly, gold. There is also wired jewelry in the form of exclusive designer jewelry released in a limited edition. Rhodium plating is not used for products from the mass market segment.

The rhodium procedure is carried out in almost every workshop that carries out repair and cleaning of jewelry. The process is not complicated and lengthy.

Electrochemical deposition is carried out by electroplating. A thin layer of rhodium evenly covers the entire surface of the silver product.

The coated product is protected from external factors such as contamination, sudden temperature changes, excessive humidity or dry air. Increases the resistance of silver to damage. Strengthens the strength of silver items. The metal has an extra shine.

Silver is rhodiated with a metal without a ligature, which means the absence of any impurities in it. Other options are technically impossible. As a rule, a test of rhodium silver is marked 925. The coating increases the quality of the item, but also increases its value. The law states that worn products are branded according to samples of the materials from which they are made.

Silver rhodium-plated products are visually a copy of platinum - the most expensive metal used in jewelry production.

The advantages of rhodium include the choice of coating color. A chic and at the same time modern option is to make the black rhodium. You can also change the old decoration, giving it newness with a new coating color. But even with the external simplicity of the process and the availability of suitable equipment, it does not mean at all that anyone can handle the application process. It is unrealistic to carry out the procedure of delivery at home without proper experience. The risk is high to comprehensively ruin the surface of the decoration.

Composition and properties

Rhodium belongs to the noble metals of the platinum group. The metal does not face oxidation and corrosion. It is distinguished by high hardness, 2 times higher than that of platinum and 5 times higher than the hardness of silver.

At the same time, rhodium is rare - only a few tons of metal are contained on the entire planet.

By itself, it is not plastic enough to be used in jewelry, but as a covering material, it is ideal for silver and gold.

Coated jewelry lasts much longer, protected from the appearance of patina and plays with a specific shine in the light. Under suitable external conditions, the rhodium coating is capable of reflecting up to 80% of the rays of the visible spectrum. In gold, this indicator is only 60%, it turns out that the brilliance of rhodium is much brighter. The main advantages of rhodium, prompting the widespread use of it as a coating of jewelry:

- high characteristics of hardness and strength;

- gloss not fading over time;

- corrosion resistance.

After six months of operation, a standard ring made of pure silver is covered with small scratches and needs to be polished. For similar rhodium-plated jewelry polishing is not needed for several years after purchase. The cold white-silver color of rhodium strongly resembles platinum. If you place a wired silver ring and an analogue in white gold next to it, it will be difficult to find obvious differences in the products. This fact allows you to combine jewelry from different metals in a set.

Strength

Rhodium is distinguished by great strength. Jewelry coated with this metal becomes more durable and lasts longer for the owner. Rhodium-plated silver jewelery is more resistant to deformation, in comparison with ordinary jewelry. On the Mohs scale, the hardness of rhodium is 6.

According to the characteristic of a mineral with a similar hardness, it can scratch the glass and process it with a file.

Pure gold and silver have a strength value of only 2.5. This slightly exceeds the hardness of a material such as gypsum, which can be easily scratched with a fingernail.

Comparison with ordinary silver

Externally, this metal is similar to the prestigious platinum and white gold. However, wired silver differs from the usual one in a number of ways. Rod metal shines better. It can be determined by the specific strong radiance under the sun's rays. Pure metal cannot boast of brilliance, but has a grayish tint.

Compared to sterling or pure silver, wrought has a completely even color and demonstrates special ductility due to the inclusion of copper in its composition.

The oxidation rate is affected by the mass fraction of copper in the alloy and the skin type of the wearer.

Production technology

On an industrial scale, rhodium can be obtained by processing native platinum. It turns out the material is absolutely resistant to acids with one drawback - fragility. Therefore, it is used only as a coating for various metal surfaces.

Rhodium is applied to the metal by the galvanic method. In this case, an auxiliary product serves as the anode, and the decoration itself acts as the cathode.

As a result of galvanization, a layer of 0.1-25 microns in thickness occurs.

Before proceeding to rhodium, the item needs careful polishingotherwise the coating will only emphasize the existing flaws on the surface. The best option is to process things immediately after purchase (if this was not done during the production process). The next step is to thoroughly rinse and degrease the product. Then immerse it in a bath of concentrated rhodium sulfate.

The solution should be evenly distributed over the entire surface of the product. After that an electric current is passed through the solution. A chemical reaction occurs, the consequence of which is the release of rhodium. It covers the entire area of the product with a thin layer.

You can buy a solution for self-rhodium silver in a jewelry workshop or a specialized store.

Application

In everyday life, rhodium products are not found, since it is difficult to process and melt, while it is unplastic and expensive. But for the hardness and brilliance of rhodium in honor not only among jewelers. Rhodium is covered not only with silver jewelry, but also with instrument mirrors, reflectors on searchlights, liquid crystal devices, parts of nuclear reactors and laser installations.

Care Features

The purpose of the rhodium coating is to protect silver from minor scratches and destructive natural factors. But also sheltered jewelry needs a careful attitude and care. The item must not come into contact with aggressive substances such as varnishes, their solvents, ammonia, alcohol compounds, cleaning products, including abrasives.

It is better to store worn jewelry in separate cases, avoiding contact. Jewelry should be removed at night, before taking a bath and playing sports.

After applying the caring compositions, you should wait until they are completely absorbed, and only then put on the product.

The rhodium layer is destroyed by the action of detergents with an aggressive composition - washing powders, dishwashing gels, etc. Before hand-washing and washing dishes, it is recommended to remove worn rings and bracelets.. Jewelry can also deteriorate from contact with alcoholtherefore their interaction with all alcohol-containing compounds is not allowed.

Do not scrub your hands with rhodium-plated rings. Any abrasive particles damage the protective layer. When caring for items coated with rhodium, special care products for cleaning silver will not work. They are allowed to clean only ordinary silver, not having any coating.

Contact with sweat also negatively affects the rhodium coating, therefore jewelry with this coating is not for use in the gym. They should be left in the locker room.

The same goes for pool trips, as chlorinated water can lead to the destruction of the rhodium layer.

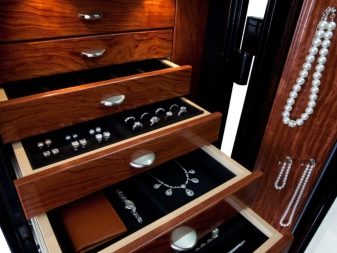

Products with rhodium plating also need proper storage. For this, a standard jewelry box will do. Use cardboard boxes for storage is unacceptable! This is because there may be sulfur in the composition of the cardboard, and it entails the oxidation of silver with the loss of its external attractiveness. If the product is not worn for a long time, it is recommended to wrap it in a flannel.

Even a durable rhodium-plated coating begins to wear off over time. You can restore it in any jewelry workshop. The old layer will be professionally removed and a new one will be applied instead. The product will shine again, attracting attention with its smoothness and the play of light on a snow-white surface.

Rhodium plating technology was invented specifically to extend the life of silver jewelry.

Therefore, when buying, the cost of coverage with rhodium, which is already included in the final price for the product, is taken into account.

Sometimes there is more benefit in buying ordinary silver and subsequently rhodiating the item in the workshop.

Basic Rules

How to clean?

Rhodium damage is not easy, but possible. When the surface of the coating is scratched or a crack has appeared, polishing alone will not be enough - you will need to completely remove the layer and rod again. In case of breakage or violation of the integrity of the product coated with rhodium, it will have to be restored again.

Rhodium plating should be renewed at least once every 3 years (or once every 6 years - depending on the intensity of use of the item).

It will not be possible to protect an antique jewelry or an antique stylized decoration with rhodium from damage. The layer will lie unevenly, and the acquired radiance will not be in harmony with the old look of the product.

Given that coating with a layer of rhodium - an expensive procedure, its presence significantly increases the cost of finished jewelry. If you liked a wired item with a stone that is presented as precious, you need to ask gemological certificate to him from a consultant. This will protect against the acquisition of a fake. You also need to make sure hallmarks indicating the sample. By law, it must be present on any silver item.

The list of products suitable for cleaning homemade jewelry is very limited.. The easiest way to cook soap solution water-based and thoroughly wash it with jewelry that needs to be cleaned. Then they have to rinse in clean water and gently but thoroughly blot with a piece of soft cloth. The same algorithm is used to clean jewelry with cubic zirconias and other precious stones. Products must be cleaned as they become dirty and periodically carried out maintenance with a preventive purpose.

For what and what products are born, see the next video.