Silver is one of the most popular types of precious metals. It is actively used for the manufacture of jewelry, medical instruments and even elements of technology. Pure silver is not able to store gloss and color for a long time. And since this metal is considered soft, it is prone to deformation.

Comes to the rescue processing method called rhodium. He is in great demand, has several advantages. There are some differences between ordinary silver and rhodium. To the question of whether it is possible to carry out the procedure at home, you can get an answer below.

What it is?

Silver rhodium used by many manufacturers. This processing method designed to preserve the beauty of precious metal products. Over time, silver becomes almost black, as it undergoes a fairly active oxidation process, which begins after a certain time. Processing will make a metal product more resistant to environmental influences., and this means that its presentable appearance will last much longer.

It should be noted that rhodium belongs to the platinum group, is also considered a noble metal. In appearance, it resembles silver, which has a cold tint. Its properties make it possible to resist corrosion; therefore, the metal does not darken and scratches do not appear on the surface.

Due to the fragility, rhodium is not used as a raw material for jewelry, as it does not have sufficient strength. But as a coating, it is suitable for many precious metals.

Why is it necessary?

To improve the production characteristics of silver, copper and other impurities are added to it. Corrosion properties due to this are reduced. This suggests that copper is able to reduce the function of opposing alloys to the external environment, so the metal begins to darken over time. Black on silver jewelry looks pretty unattractive, so you have to go to a jeweler to give them for cleaning.

But in order not to waste time and money on this, silver can be rod, so that the metal becomes harder, reflective and chemically stable, and metal needs these qualities most of all. It is in order to extend the life of the product and it is necessary to make silver processing a representative of the platinum group. The result will be immediately noticeable, in addition, the obtained properties are stored for a long time.

How is it different from usual?

The difference between rhodium and ordinary silver can be seen even with the naked eye. If you look at the decorations, then the finished items look shiny and the simple ones look pretty dull. Of course, it all depends on the taste and preferences of each person. There are people who prefer shine to the characteristic shade of metal.

But rhodium affects not only the appearance. If you process a silver product with this method, it will be more resistant to corrosion, and also increases its wear resistance. In addition, the metal itself becomes hypoallergenic. The service life of the products is significantly increased, which is another important advantage.

How to make at home?

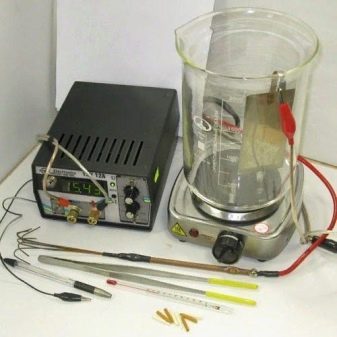

Jewelry shops offer services for rhodium silver products. And although the process is quite simple and does not take much time, everything needs to be done carefully so that the result is positive. The essence of the work is to apply a thin protective layer by galvanic method. Electric charges of rhodium are evenly distributed on the surface of the silver jewelry.

If you decide to do this yourself, follow the step by step instructions.

- The product must be degreased, remove dirt from it and rinse well.

- Liquid is poured into the container, then a rhodium sulfate solution is added.

- After that, an electric current is passed with the force that is required for a certain layer thickness. However, there is one condition: the procedure requires galvanic apparatus.

Rhodium is not poisonous, so it is used even when applied to tableware. And you can also ask for help from a master who will carry out the processing in a few minutes.

Where is it used?

Silver rhodium plating is used not only for the processing of jewelry, dishes, and similar products. The inertness and hardness of the metal attracts other specialists. For instrument mirrors this method is also used. In addition, experts use it during the production of reflective elements for searchlights, liquid crystal devices, and even nuclear detectors. Thus, it can be noted with confidence that this process is in demand. in industry by professionals of different directions.

How to care?

Rhodium plating also needs care, so it’s useful to know a few rules.

Do not clean any treated silver jewelry with abrasives.as they can damage the surface. In contact with household chemicals, it is better to take off products (rings, rings, bracelets, and so on).

To clean the product, you must rinse it with warm water, wipe, and then, using a jewelry napkin, polish.

It is periodically recommended to show products made of rhodium-plated silver to a specialist: you may need a second coating.

Products made of precious metals attract their diversity and uniqueness. In addition, no woman will deny herself the pleasure of putting a silver ring on her finger or complementing the image with a delicate bracelet.When choosing products from this metal, it is necessary to pay attention to the characteristics and strength indicators. But if silver is wired, you can not worry about it.

The following video discusses the process of rhodium jewelry.