Most people wonder about the possibility of melting silver products at home. This is not surprising, every year more and more silver things appear in the houses, which eventually lose their shine, go out of fashion and simply become unnecessary. Let's consider in more detail how to melt silver at home.

Melting temperature

Quite often, people do not even imagine how many silver items are in their home. And we are talking not only about visible things, but, for example, about radio components that are present in various techniques. If you collect all the contacts into a single whole by self-remelting, you get a heavy piece of precious metal, the price of which will be quite high. You can re-make silver with your own hands not only into a single ingot, but also make a new jewelry. However, before getting acquainted with the methods of melting, you need to find out some details about silver and its properties.

The history of silver began more than 6000 years ago. Evidence of this are archaeological excavations in Turkey and Egypt. Another name for this precious metal is “lunar”. According to the esotericists, it is the moon that patronizes silver. The reflection of the silver stone is very similar to the cold brilliance of the moon.

Thanks to the hard work of physicists and chemists, the following characteristic properties of silver were revealed:

- the density of the pure metal is 10.6 g / cm³;

- differs in softness and plasticity;

- has a high level of melting;

- differs in high heat conductivity;

- has high electrical conductivity;

- possesses reflective ability.

Having decided on your own to remeasure old silver, you need to know the exact temperature at which this metal will turn into a liquid consistency. The raw material used in melting is called a “charge”. It is necessary to heat it according to the approved safety rules and the steady observance of the technology.

First of all, remelting depends on the composition of additional impurities. With a small amount, a temperature of +760 degrees is sufficient. Pure silver becomes liquid at +962 degrees. However, modern silver products do not have a pure composition, impurities are necessarily present. Thus, the temperature of +810 degrees will help melt the silver 925.

Necessary tools and materials

The industrial mining of silver metal takes place on a large scale using special technologies, due to which it is possible not only to melt, but also to enrich the ore. The following tools are required for smelting silver products at home:

- asbestos;

- borax;

- scrap metal;

- graphite powder;

- fireclay clay;

- burner or microwave.

It is important to consider that liquid metal needs to be cooled. Therefore, before starting work, it is necessary to design a mold for reflux. If you want to melt a large piece of silver, it must be broken into small pieces. The process of making a mold is an essential part of the preparation. First of all, it is necessary to make a metal box and cover it with wax. It is filled with gypsum mixture. After solidification of the liquid mass, the mold warms up to melt the wax.

Much more difficult is the preparation of an unusual form of ebb, namely:

- quite often alloys are present in silver, which is why when melting a precious metal, it will be necessary to use a magnet to catch particles of steel and iron;

- it is necessary to make a smelter from sheet asbestos; the prepared design will play the role of a crucible;

- to protect the alloy from oxygen, borax or flux is used; the substance is poured into a container that plays the role of a smelter, after the borax acquires a dense mass of a greenish tint, a metal billet is laid out in it;

- initially the metal turns red, then it starts to melt;

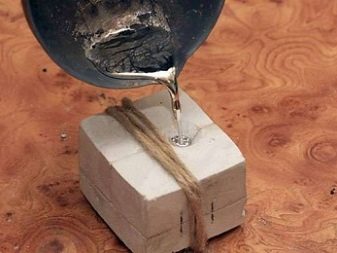

- The bright silver molten metal is poured into the prepared mold and cooled.

Important! According to jewelers, it is possible to melt silver at home, the main thing is to observe safety precautions.

Smelting methods

Today, the melting of silver at home involves such heating methods as:

- a special melting furnace that you can buy or create with your own hands, but you need to install them separately from other items, best in a garage;

- the most common microwave oven, stove or gas burner;

- There is another method for melting silver products, less popular for home use - blowtorch.

The result of the process of remelting silver products at home entirely depends on the complexity of the work. Of course, if ingots of any shape are required, no problems arise. If the idea requires the creation of a beautiful product, it is better to contact the master. Unfortunately, having no work experience, it is impossible to make an unusual decorative format for jewelry, especially at home.

The melting of silver products by any method presented requires compliance with safety requirements. Even a small drop of molten silver can burn the skin to the bone. Asbestos is laid out under the hot crucible. As an additional protection, it is best to have a fire extinguisher on hand.

Burner

The process of melting silver by means of a gas burner occurs in stages, namely:

- you need to choose high quality silver, it is best to consider 925 jewelry; if the piece of silver is large, it is necessary to split it into small parts;

- to start melting, you should prepare a special crucible from heat-resistant materials;

- it is necessary to create a mold for casting the product - you will need to combine 1 part of gypsum and 7 parts of sand, add a little water, so that the mass acquires the consistency of thick sour cream; the prepared composition is poured into a separate container, then an object that needs to be cast is taken, lubricated with soap and lowered into an unhardened gypsum mixture, waiting until the mass begins to harden;

- now you can begin to melt the silver product with a burner; it is important to note that the flame source should be directed only to the melting product;

- liquid silver is poured into the mold and left to cool completely;

- it remains only to separate the finished product from the gypsum stone; if the product is firmly held in the base of the form, you can use the available means.

In the microwave

In the absence of a burner and a melting furnace, silver products can be melted using a conventional microwave. This method is the simplest and fastest. It includes the following steps:

- a thermal barrier should be prepared where fireproof containers will be immersed;

- the crucible is filled with a charge;

- filled containers are sent to thermal protection;

- in the settings of the microwave oven it is necessary to set the maximum power and set the time to 35 minutes;

- the end of the microwave operation is accompanied by a characteristic sound, after which liquid silver is poured into the prepared form.

How to remove impurities?

Few people know, but at home you can clean silver from various impurities. The concentrate to be cleaned is placed in a glass container, after which it is poured with nitric acid and put on fire. As soon as the precious metal becomes liquid, ordinary salt is added to it. With this reaction, silver chloride is precipitated. Then the resulting substance must be washed with water and filtration done.

The next cleaning step is metallization. The resulting silver chloride is diluted with hydrochloric acid. With the help of zinc chips and heating is precipitated. The resulting sand mass of a dark gray hue is ready for the melting procedure.

On how to melt silver at home, see the next video.