Silver, undoubtedly, can be called one of the most common types of precious metals in the whole world; various products are created from it, including jewelry, medical and even spare parts for electronics. You can name various places where there are deposits of this metal, but not in its pure form. Often, raw materials must be processed to remove silver without impurities. The process of mining and processing silver is laborious, requires serious investments and professionalism.

Types of deposits

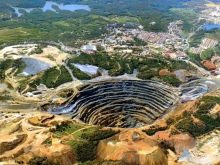

Silver is formed in mines of various types. Often, metal can be found in vein, as well as mineralized zones, which are located in the volcanic zone. The ore body lies deep in the strata, and to get to it, requires special equipment and a large team of specialists.

The main source of precious metal are considered copper and lead-zinc deposits. They can also be attributed to copper-pyrite, pyritic-metal and other types of ores. The geological situation differs depending on the geographical location and mineral deposits. Gold-silver and silver deposits are located in the Pacific ore belt.

The metal in question is found in nature with an admixture of other materials, therefore, for mining it is necessary to carry out a whole procedure in order to obtain “white” gold for further use.

Natural mineral formations contain a significant proportion of this precious metal. A quarter of the total silver is mined from there, followed by polymetallic ores, including copper, cobalt, gold, nickel, in which this noble metal is a by-product.

List of silver mining sites

Silver is considered the next popular precious metal after gold. Experts estimate the entire volume of reserves at about 600 thousand tons. About 20 thousand tons are mined annually, and in 2018, American geologists reported 27 thousand tons. You can name just a few countries that make significant investments in this industry. Two centuries ago, all silver mining was concentrated in South America., and to this day this continent is not inferior to the first position on the world stage in the amount of "white" gold.

In the world

Peru ranks second in silver mining after Mexico. Perhaps these two countries are included in the list of leaders in finding this material on their territory. IN Poland there are also deposits of the precious metal in question. Peru and Poland have 110 thousand tons of silver each. But if we talk about production volumes, Mexico is a leader among all. There are a huge number of companies that produce products from precious metal, because there are a lot of raw materials.

In Mexico, more than two hundred mines are actively operating, since a significant amount of silver is mined from there. Major deposits include La Encantado and Las Torres. Deposits in the states of Hidalgo, Chihuahua and Zacatecas make up a fifth of the "white" gold of our planet. Peru is on the same list as Mexico.

There are small mines throughout the country, thanks to which 17% of the total silver is mined.

Returning to Poland, it should be noted that within Lublin there are large deposits of metal. In a Chinese area called Ying, there is a third of silver reserves from across the country. No wonder this country is considered one of the richest in metal. Silver industry is also developing in the cities of India, Argentina, the United States, Australia, Chile and other countries, although not on such a large scale.

In Russia

As for our country, at the moment the reserves are almost 70 thousand tons. Deposits are located in different regions of Russia. In 2019, he took the leading position Magadanwhere the figure reached 236 tons. The Chukotka Autonomous Okrug was in second place, followed by the Khabarovsk region.

However, they are also engaged in mining Yakutia, Buryatia, Krasnoyarsk Territory and the Orenburg Region, although in these regions there are small deposits. "White" gold in a large volume is in the bowels Dukat hub which is located in Magadan region.

There are four deposits, here about 30% of all silver of the Russian Federation is mined.

A lot of silver and in Ozernoye (Republic of Buryatia), therefore, many precious metal products are made there. The total ore reserve reaches 157 million tons, of which about four and a half thousand tons of silver. The pyrite ores of the Urals also have deposits of precious metals.

Summing up, we can confidently say that the leading countries in silver mining have remained so for many years, this list includes Mexico, China and Peru.

How to get it?

It is extremely difficult to find nuggets in nature - this is an exception. The main source of silver are ores of various types. This metal is actively used not only in the jewelry sector, but also in the manufacture of mirrors, the production of medical equipment and even mechanical engineering. At first, silver mining in Russia was not so widespread, as large financial investments were required, which could pay off only after many years.

However, today there are many mines, thanks to which the country has taken its rightful place in this area, moreover, this industry continues to develop.

Obtaining a substance from ore is rather difficult; a long and laborious procedure is requiredin which different specialists are involved. And since the value of silver is high, it was necessary to develop technologies for high-quality extraction and processing.

The question of how it is mined is of interest to many. First thing you need discover plotwhere there are metal reserves. This is done by geologists who carefully study rocks in different regions, use special instruments that are difficult to do without. After them, the miners are taken for work. Necessary lay explosives in pre-prepared holes. After the explosion, large fragments of ore rise to the surface by special equipment.

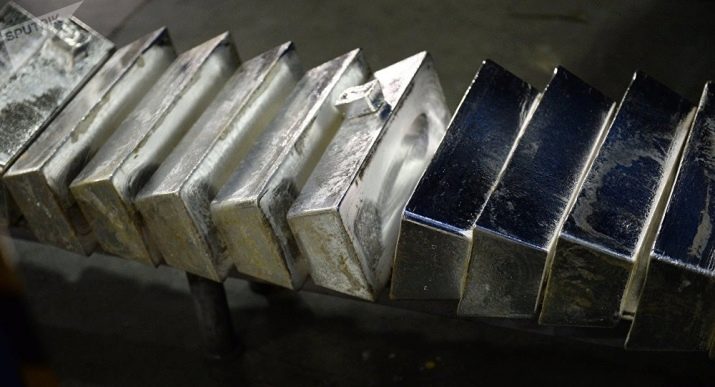

Next is necessary grind ore to the state of sand. For this, special units are used. The powder is mixed in a container with water and acid. Then the solution is passed through filters, the silver mixture is attracted by zinc. For melting, gas furnaces are used, where in the forms the mixture turns into a liquid substance. Due to its heavy weight, silver settles at the bottom, which is why impurities are easy to remove, because they are on the surface.

It takes several minutes for the metal to freeze, after which the ingots are sent to the production of various products or put up for sale.

What methods are used to extract silver?

As mentioned above, the ore contains many impurities that must be removed. Cyanide most popular in such cases. Alkali dissolves the material, then the mixture is filtered. The second method is called amalgamation. Silver combines with mercury, which leads to the formation of compounds. When mercury is squeezed out, the substance becomes solid. The mixture is filtered, as in the first method, the mercury is evaporated, after which ingots are obtained by melting.

Radio parts can become a raw material for silver. In televisions, tape recorders and other types of equipment there are elements from this precious metal. To get started, you need to remove all other parts. Samples dissolve at 60 degrees Celsius in nitric acid. After that, the mixture is poured into hydrochloric acid and heated. It is necessary to mix the composition until it reaches a viscous consistency, then cool and add a little of the same hydrochloric acid so that the precipitate completely precipitates. The solution must be left for twelve hours, then filtered, dried and melted by adding baking soda. Other components can be washed off with a stream of plain water.

Silver can be called unique metal. It has thermal conductivity, chemical resistance, high ductility and other properties. Thanks to this, it is actively used in electrical engineering, medicine, jewelry, as well as other industries. Experts say the stock of precious metal around the world will last another twenty years. Demand for silver is regularly increasing due to the opportunities it provides.

Do not belittle the benefits of this precious metal, because it is used not only to create expensive jewelry - it has also spread in the medical industry, as surgical instruments and various professional equipment are made from the material.

To extract any precious metal, it takes a long time, a lot of work and considerable investment. But the same can be said about the processing of raw materials, because it takes several steps to get the material in the form in which it can be used in industry.

An interesting report on the extraction and production of silver is in the video below.