Wood carving is one of the oldest decorative arts that has survived to this day. In the time of ancient Russia, this occupation was considered rather difficult, since there were no technologies that exist at the present time, and there was also a limited set of tools, thanks to which you can create the most incredible patterns on a wood surface.

Fortunately, today technology has stepped far forward, and anyone can easily master this skill and delight others with their work. But in addition to skill and talent, it is necessary to acquire suitable tools, without which the process of woodcarving will be simply impossible.

Features

The toolkit of masters engaged in woodcarving is quite wide, because one or another element is needed to perform certain actions. Since the threading process itself is divided into several types, then to complete each of them you will need the appropriate tool.

In this regard, it becomes clear that the arsenal of a true professional is very wide and deserves special attention. Consider what tools are needed for woodcarving, how they differ and what work they are intended for.

In addition, it is necessary to carefully study the features of the choice of tools and the nuances of caring for it.

Kinds

There are many varieties of tools for woodcarving that perform one or another function, and this is their hallmark. Each of them should be considered separately, but for convenience, you can divide them into two main groups: tools that are powered by electricity and through manual interaction.

It is worth noting that to this day both groups are actively used, and some masters even prefer hand tools.

Electric

Perhaps the most widely used electric tool can rightfully be called a drill. The dimensions of this unit are so diverse that the range makes it easy to choose the right model depending on the amount of work. In addition, in addition to models that operate from a direct network connection, there are also small mobile options that are powered by rechargeable batteries. Also, the drill has many nozzles, so the range of its use is very wide.

An electric jigsaw also has a fairly large demand, given that its functionality is equivalent to hand tools such as openwork or bow saw. Due to the fact that the device has electronic control and speed control, its vibration is minimal, which means that the movements will be more accurate. Also, the device allows you to change the sawing element and select the appropriate option with certain teeth.

To chamfer, cut edges and grooves, and also select a quarter, you should use a manual milling electric machine. In some cases, this tool is used to make decorative screw threads.

When the master needs to cut a wood element in any direction and at any angle, while maximally protecting his life and health, you should use a circular or circular saw. Some models are provided with an electronic control system that allows you to smoothly start work and gradually increase the speed of revolutions for more accurate slicing.

The wooden element is adjusted to certain parameters and trimmed with an electric planer. Due to the fact that the knife block has a special fence, the master, the product and the elements of the device itself are protected from damage as much as possible.

Belt and disc machines for grinding, which is done through vibration.

These tools are necessary to prepare the wood element for polishing and then apply a protective varnish.

Hand held

There are quite a lot of hand tools for working with wood materials, and they are divided into several groups, including a certain number of items. So, as a separate group, it is worth considering chisels, flat and rounded models of which have their numbering and designation.

- The first number is the chisel, designed for general work, making direct cuts and performing medium-sized finishes. Its width is 12 mm, and the shape is straight and flat.

- Chisel No. 2 also has a width of 12 mm and is used to trim small parts and perform some work. Its oblique flat shape allows you to make movements more accurate, and parts on the workpiece - more accurate.

- For fine artwork, a cerasik is ideal - a rounded chisel with a width of only 3 mm, which is also indicated by number 3.

- Chisel No. 9, which has a straight, rounded shape and a width of 25 mm, will help to perform quick cutting and facilitate general work.

- Chisel No. 10 has a round shape and 8 mm wide, which makes it a very suitable option for some general works and cutting grooves.

- Curved 9 mm model No. 14 is ideal for cutting bends and planar parts.

- Also, a width of 9 mm has a chisel No. 21, designed to make rounded recesses with their subsequent decoration. This model has a spoon shape and is also called klukarzoy.

- Spoon Klukarza No. 27, whose width is 12 mm, is the most suitable tool for creating a more embossed, slotted and winding surface.

- A forged right angle number 39 is designed for cutting letters.

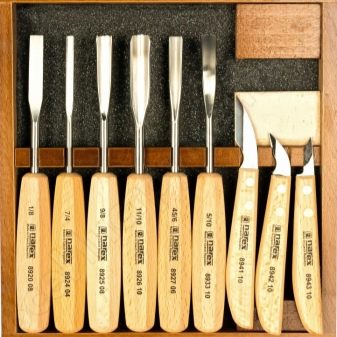

There is also a special professional set of chisels, consisting of only 7 items that are necessary to perform more subtle and more complex work:

- angular spoon chisel of a flat form, designed for left-side and right-side work (depending on type);

- klukarza having a reverse bend;

- a spoon model of a chisel equipped with a step-shaped bend;

- a chisel, the shape of which resembles a fish tail (the name of this tool is appropriate);

- wing-shaped corner;

- curved tool having a rectangular groove;

- Spoon model equipped with a rounded rectangular groove.

In addition to all the listed types of chisels, other tools are also used, without which the process of woodcarving will simply be impossible or noticeably complicated.

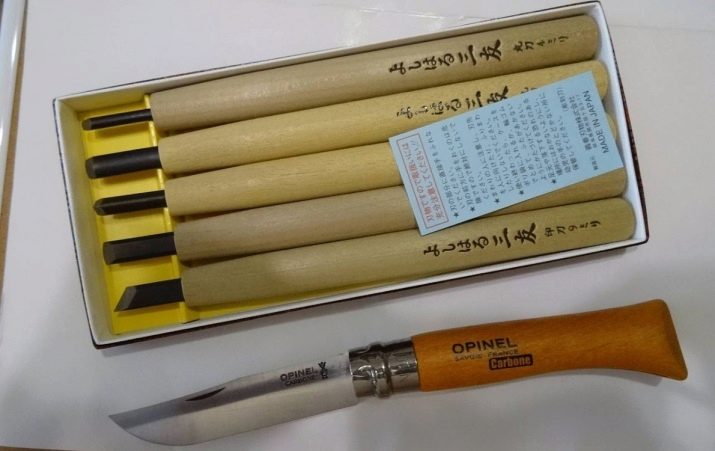

For example, knives for detailed study of elements. Usually, three types of this tool are used: a folding model, a product with a conventional fixed blade and with a replaceable cutting element.

Hand saws are necessary for cutting curved parts, removing excess workpieces and trimming edges.

To make it easier to remove the bark and remove excess wood, it is best to use a brace. Most often, the tool is used to make wooden dishes.

A planer is perfect for figured workpiece processing. A multi-stage tool system and teeth with curly edges help to give the product the desired shape.

Actively used abrasives, plows, cycle, hand rotors and drills, hammers and some turning tools. You may also need tools such as mallets, tesla and minting, making it easier to work with chisels and knives.

Manufacturers

When choosing a tool for woodcarving, it is necessary to pay attention not only to the model, type and individual characteristics, but also to the manufacturer of the goods offered. In some cases, this particular factor is the most significant and provides the most complete information about the quality of tools.

For instance, modern Japanese equipment has very good characteristics, since manufacturers do not skimp and do not save on the quality of materials. Moreover, the cost of tools remains at an average level, so they are affordable for masters with different skills.

The Czech company Narex produces high-quality tools, the metal part of which is made of a special alloy of stainless steel. The material does not bend, is resistant to temperatures and, with proper sharpening, remains sharp for a long time.

Tools made in Germany, Sweden, Russia and Poland are also famous for their good quality.

But Chinese production should be avoided, since it is in this country that low-quality fakes are made and metals that are not durable are used.

Which to choose?

With a wide assortment of various products, including tools for woodcarving, it is quite difficult to choose a good set and still not be mistaken. Of course, you can always ask for help from a store consultant. But what if you buy goods online or expect a lower price segment than they are trying to impose on you?

Consider a few simple tips that will help facilitate the selection and avoid common mistakes.

- It is not necessary to chase expensive tools, since the high cost does not at all endow them with the best qualities. Attention must first be paid to the characteristics.

- The main materials used to make quality knives and chisels are steel and wood. In the presence of other metals and plastic in the characteristics, it is worth seriously considering the quality and reliability of such a product.

- In order for you to be comfortable working with the tool, you need to hold it in your hands and perform several manipulations that simulate working with a tree. Based on the sensations, you can choose a product with a suitable size handle.

- The power tool must be selected especially carefully, making sure of the quality of the wires and the reliability, as well as the integrity of the housing.

- There are many sets for beginners, but not always their functionality is similar to the tools for experienced professionals. Therefore, it is better to turn your attention to a quality set for masters with any experience in order to avoid difficulties and overpayments.

- The same applies to gift sets, since the quality of most of them can be rather doubtful, unless, of course, we are talking about tool sets of trusted brands, the contents of which remain unchanged, but only the packaging differs.

How to sharpen?

To keep your tools in good condition longer and still perform their functions clearly, you must take care of them. Processing and sharpening are the main stages of care. But if processing can be easily done at home, then what to do with sharpening?

Regular contact with specialists can be tedious and very expensive, therefore it is recommended to learn how to sharpen your tools yourself, at home.

First of all, it is necessary to indicate what is needed in order to sharpen tools for woodcarving:

- fine-grained abrasives;

- donkeys with oil or water;

- To simplify the process, you can use electric sharpening devices.

The work is carried out in several stages.

At the first - the blade is sharpened to the formation of small burrs on the surface.

At the second stage, these burrs are smoothed out and the tip becomes smoother.

At the third stage, grinding is performed, in which the surface of the tool acquires perfect smoothness and a mirror shine.

The final stage is the processing of the device and the final check of the tip on a wood surface.

How to do it yourself?

Often, many professionals, not wanting to work with a purchased tool, prefer to make it with their own hands. For beginners, this process may seem rather difficult, but if you follow the step by step recommendations, then you can easily cope with the task.

- First of all, you need to determine the parameters of the products and make drawings.

- If you have experience working with metals, then it will not be difficult for you to make a tip of the desired shape by cutting it from a large sheet or melting it using a special form.

- The dimensions of the cutting part are recommended to be customized individually for you, taking into account the existing skills.

- Making a wooden handle from a craftsman for whom woodworking is not something new and unknown will not be difficult. Its shape and size should also be as comfortable as possible for you.

- Next, the homemade tip must be fixed on the handle so that even with a strong pressure it does not come off, as this can be quite traumatic.

- To hold the blade tighter, its end can be tightly screwed into the handle or use a special adhesive composition for metal.

- After that, it is necessary to polish the metal part and treat the wooden handle with oil compositions and varnish.

- After drying the tools and sharpening the tool, you can safely use it in your work.

Tips for beginners to carve in wood in the next video.