At the end of the 19th century, French scientists Shore and Mayo, using an alloy of nickel and copper, created a metal that could very successfully imitate natural silver. The alloy began to be used for the manufacture of cutlery and crockery, and then jewelry began to be made from it, as well as medical instruments and various details for technical use.

Cupronickel quickly became fashionable, so in almost every family whose wealth did not allow silver cutlery, forks, spoons and feast knives were made of cupronickel. The cost of such products was not too high, and in appearance they were difficult to distinguish from silver ones. However, the housewives had to carefully clean the tableware from cupronickel so that it looked expensive and presentable.

What it is?

The chemical formula of cupronickel implies compound of copper and nickel metalstaken in certain percentages, the result of which is an alloy that looks shiny in appearance and has the color of silver. Such a metal became a stumbling block for ordinary people who did not know how to distinguish silver from cupronickel and often fell into disarray, acquiring cupronickel products at the price of silver.

Sometimes iron and manganese were added to the alloy of copper and nickel to increase the density and strength of the material. If a magnet was brought to such an item, then one could notice that it exerts its magnetic properties and is magnetized, while silver items were not able to display magnetic properties.

After several experiments, experts began to make nickel silver of various brands, which even got their names and found for themselves certain areas of application.

Appearance

Cupronickel was originally conceived as an inexpensive alternative to silver. In appearance, the products made of an alloy of copper and nickel did not differ from silver, they looked at the same time elegantly and soundly, but at a price they were much cheaper than silver analogues. It was especially difficult to identify cupronickel objects if gilding, silvering or a layer of rhodium were applied on top of them. The difference between silver and cupronickel lies not only in the composition of their alloys, but also in the principles of caring for products.

Structure

The alloy, consisting of a copper-nickel base, belongs to the class of non-ferrous metals. Mostly cupronickel consists of copper, and nickel and other additives act as a ligature, which gives the finished alloy hardness and strength. The composition of the metals applicable to the alloy allows the material not to corrode, being oxidized in air. It is the properties of stainless metal and its silver sheen that have become the most important and valuable in cupronickel.

Initially, cupronickel consisted only of copper and nickel, but over time its composition became more perfect and diverse. So there were various brands of cupronickel. The composition of metals in modern cupronickel may be as follows:

- copper - from 65 to 90%;

- nickel (sometimes with the addition of cobalt) - from 5 to 30%;

- Manganese - not more than 1%;

- iron - not more than 1%.

In some brands of cupronickel zinc is present, which replaced a certain part of nickel. The resulting alloy had a noble silver-steel color and was often used to make coins. Due to the variety of cupronickel alloys, it came to the point that ignorant people began to call silver plated brass spoons made of brass only as cupronickel.

Modern alloy nickel silver is a durable, stainless material. Due to the high copper content, the surface of cupronickel products fades over time.

To preserve the original appearance of the product, it is required to regularly clean and polish both for preventive purposes and after use.

Marking

For products made of cupronickel alloy, there is a brand (test), consisting of two letters: M and N. These letters indicate that the alloy contains copper and nickel. If Ж and Мц were placed next to the letters МН, then such symbols indicated that the alloy contains iron and manganese. In addition to the letter designation, the stigma on cupronickel products had numbers. For example, the MNZhMts 30-1-1 sample indicated that, in addition to the copper base, the alloy contains 30% nickel, 1% iron, and 1% manganese.

Products made of nickel silver were made in our country before the collapse of the USSR, after which a similar alloy was already produced with the addition of zinc. The result was a nickel silver - one of the varieties of cupronickel. Items made of a copper-nickel alloy without zinc additives can now be purchased unless in antique stores. In terms of appearance and strength, products from nickel silver are not visually distinguishable from silver ones, only silver in contact with a damp surface and in air can darken, and the alloy of nickel silver with zinc remains unchanged.

A hallmark of the nickel silver is its stigma. And if cupronickel is marked with a breakdown of MN, then the alloy with zinc already has a different marking - MSC. Sometimes it happens that there is no sample on the product. Then, to determine the composition, you need to know the date of its manufacture or evaluate the color of the product for the presence of a yellowish tint in it: if there is no such shade, then you have a nickel silver, not nickel silver.

Metal properties

The characteristics of the copper-nickel alloy are as follows:

- the alloy does not enter an oxidizing reaction with oxygen;

- not exposed to salt and acid solutions, including sea water;

- shows resistance to gases;

- well prone to soldering, polishing;

- the density of the material is 8900 kg / m3;

- electrical resistivity is equal to 284-285 nOhm / m, exceeding copper resistance by about 20 times;

- if manganese and iron are absent in the alloy, cupronickel will be a conductor of electric current;

- without iron impurities in its composition, the alloy will not have the property of magnetization;

- the strength of cupronickel is comparable with the strength of steel;

- tensile strength of the material is 380-400 MPa;

- Brinell hardness level is 66-70 units.

Cupronickel is considered a more durable alloy than silver, while its weight is significantly less than that of a noble metal.

Melting temperature

To give cupronickel alloy hardness, a special heat treatment is carried out, which is as follows: the alloy is heated to 260-300 ° C, and then allowed to cool slowly in the furnace, naturally reducing the temperature. This process is called self-priming. With its help cupronickel is made very durable.

Material Specifications:

- cupronickel melting temperature ranges from 1190 to 1230 ° C and depends on the composition of the alloy;

- specific heat indicators average up to 390-400 J / kg, which is manifested at temperatures from +15 to + 25 ° C;

- cupronickel composition is not susceptible to oxidative processes, provided that its ambient temperature is in the range up to + 150 ° C.

The plasticity index of the metal will depend on what composition of the ligature is used in the alloy. The more iron and manganese in its composition, the lower the coefficient of hardness of cupronickel.

Varieties of alloys

To date, more than 65 different metal alloys are known, which belong to the general group of cupronickels. Each such alloy has its own name and properties, which is reflected in the marking and percentage of the material.

Consider the most common alloys.

- Monel. The metal alloy contains up to 66-67% nickel. This material has found wide application in the manufacture of medical instruments; it is used to produce products necessary in the oil and chemical fields, in the shipbuilding industry.

- Constantan. The alloy contains no more than 40-41% nickel, which gives the material high hardness and strength. This material is used for the manufacture of machine tools and appliances.

- Nickel silver. The alloy contains up to 15% nickel in its composition, and zinc is also added as a ligature. This cupronickel alloy is used for the production of state insignia badges, coins and jewelry are made from it, as well as parts used in precision instrument making.

Zinc is not used for the manufacture of cutlery and tableware, and so that during the meal there is no metallic taste, the surface of the cutlery is covered with a thin layer of gilding or silver.

Areas of use

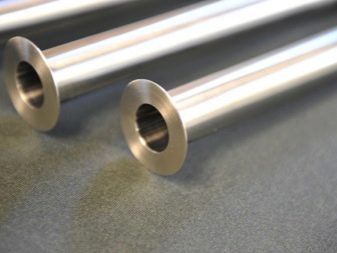

Since nickel silver is resistant to the effects of sea salt water, it is used to make products that are used in the field of marine shipbuilding. High electrical conductivity allows the use of nickel silver alloys for the production of thermocouples, resistors and other conductive elements. Often nickel silver is also used in the automotive industry: certain parts of the vehicle’s mechanism are coated with a metal alloy to prevent corrosion.

Of the copper-nickel alloy, water valves, fittings, valves and other components of the water supply system are made. Cupronickel alloy is used in medicine: products made from this material can be repeatedly subjected to various variants of antimicrobial treatment. However, they do not rust, remaining in its original form.

Cutlery and dishes

Since the creation of cupronickel alloy, it has been used for the production of tableware and appliances, which in their beauty could compete with silver products. Sets of cupronickel spoons, forks and knives were used during festive feasts: such a table adorned the table with its bright silvery sheen. As cutlery, cupronickel alloy made vases for fruits or sweets, salt shakers, saucers, trays with a set of piles, jugs and glasses.

Dishes from cupronickel were not ashamed to give. A teapot, a cup holder, a spoon with enamel - all this was not only appropriate, but also desirable, and was presented on any occasion. Large cup of tea samovars and Turks for making coffee were often made from cupronickel. Inside, these objects could be covered with a thin layer of tin, so that when heated into the water no harmful substances would be released. Cupronickel cup holders had low thermal conductivity: putting hot tea in them, you could not be afraid to burn your fingers during tea drinking.

Jewelry

Silver shine of a noble metal alloy did not leave indifferent fans of jewelry. Cupronickel products firmly occupied their niche in this area, but not as a fake silver, but as products from a unique and sought-after metal. Jewelry made of copper-nickel alloy has a high degree of wear resistance and sophistication of appearance. They are additionally decorated with special blackening, patina is added, processed in a filigree manner.

Cupronickel is often adorned with silvering: such a surface not only has an elegant appearance, but also has antiseptic properties due to silver ions. Quite often, the alloy of copper and nickel is decorated with gilding. Mostly they do this with jewelry and souvenirs. The gold layer applied to the surface of the products does not exceed 1 micrometer, but if applied by plating, the resistance of such gilding will be very high.

Gilded cupronickel does not lose its properties even with daily use. It is hypoallergenic and safe to use in contact with skin.

How to distinguish from stainless steel?

Determining at home, cupronickel in front of you or stainless steel, it is very difficult. To facilitate the task, you can use the advice of specialists.

- Determination using a sample. On products made of an alloy of copper and nickel, they put a special brand in the form of the letters MN, which can be combined with the letters G, Mts, Ts and numbers indicating the percentage composition of the ligature. On stainless steel products there is no such marking.

- If a drop of water is applied to an alloy of nickel and copper, then after a few hours, instead of a drop, you will see a greenish stain, while stainless steel does not stain.

- Pharmacy lapis pencil leaves a dark mark on cupronickel products, but not on stainless steel.

- Cupronickel alloy possesses small magnetic properties, but stainless steel does not, since it contains chrome and nickel.

- Cupronickel alloy costs 3 times more expensive than an alloy of stainless steel, since cupronickel contains more expensive nickel.

They often try to pass off stainless steel as silver or cupronickel composition, but cupronickel is quite often found in fakes of precious jewelry, dishes and other items imitating silver.

How to care?

In order for nickel-copper alloy products to look decent and attract attention with their beauty, they must be periodically updated with cleaning and polishing. For this purpose, you can use tooth powder, chalk composition or means intended for the care of jewelry made of precious metals and alloys. It is important that such cleaning products do not contain acid components or chlorine elements, since these substances form a hard-to-remove coating on the surface of cupronickel products.

Here are some recipes that you can use to clean tableware or jewelry.

- The surface is treated with soda dissolved in water. in the ratio of 50 g of soda to 1 liter of liquid.It is not recommended to clean cupronickel with a dry powder of soda, since after this procedure, scratches may appear on the surface of the products. After processing with a solution of soda, the product must be washed with water and dried with a towel dry, as wet drops will form spots.

- Another recipe with soda: in an aluminum container you need to put a layer of foil and fill it with a solution of soda (the same proportions as in the previous version). Next, in the container you need to add the items that you plan to clean. The container is placed on the stove, and its contents are brought to a boil. Then each item is rinsed in water and wiped dry with a cloth.

- Prescription with ammonia: a little liquid ammonia is diluted in warm water and products from cupronickel are placed in the resulting solution. After some time, the items are removed from the solution, washed in clean water and dried dry, polished with a cloth to shine.

- Egg shell cleaning: the eggshell must be carefully chopped to a powder state - it is enough to take the shell from 2 eggs. The eggshell powder is placed in a large container, poured with a liter of water and 20 g of salt is added there. The container with the solution is put on fire and brought to a boil. Then cupronickel products intended for cleaning are placed in a boiling solution, and they are boiled for at least 2-3 minutes. After that, the items are removed from the solution, washed with water, dried and polished with a clean cloth.

After the cleaning and polishing procedure is completed, products made of cupronickel alloy must be removed for storage in a special box or case with a soft inner part. The inside of the storage case must be dry and clean. Usually cupronickel items are sold already packed in special boxes or cases, and therefore it is best to store products in them.

It is very important to avoid exposure to moisture, chemicals or perfumes. Also, products should be protected from rough mechanical influences. Observing these simple rules, regularly performing the cleaning and polishing procedure, you can admire your cupronickel jewelry or cutlery for many years.

For how to clean cupronickel in two minutes, see the next video.