Bronze is one of the oldest alloys, which has a long and rich history. This is one of the first such materials obtained at the dawn of 3 millennium BC. e. The role of bronze and today still remains quite important and significant. In this article, we will take a closer look at this alloy, find out its composition and understand where it is most often used.

What it is?

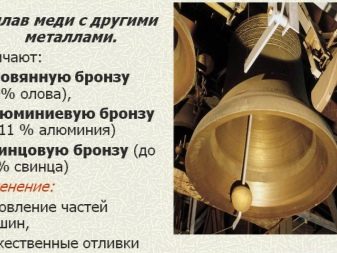

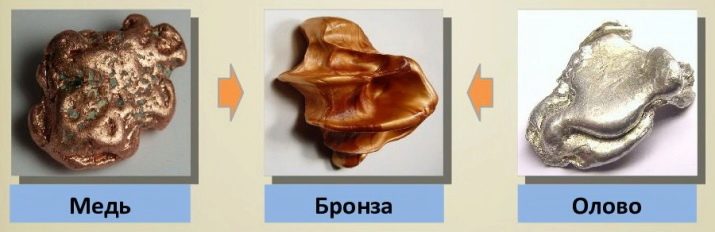

Before you start a conversation about in which areas bronze is most often used successfully, you should find out what it is. If you understand in detail the definition and features of the material in question, it is worth highlighting the fact that in The alloy contains such important components as copper and tin. Also bronze contains and a mixture of other elements, but in more modest percentages. The result is attractive and multicomponent alloy. It is copper that plays the main role in its composition, and everything else is represented by alloying elements, without which one cannot do without improving the properties and characteristics of the metal.

Bronze looks different. Its external parameters directly depend on which components prevail in its composition. So, the traditionally known alloy of saturated red tint indicates that a large percentage of copper is present in it. There are also varieties of this metal that have a cold steel coloringclose to white - a similar appearance indicates that the alloy contains no more than 35% of the copper component.

Advantages and disadvantages

The alloy in question has been popular for many years.Over the years, its relevance does not decrease, which is due to the many advantages that are inherent in it. Consider the main positive characteristics of bronze, making it in demand.

- This metal boasts a rich variety. There are many different types of bronze, for example, tin, silver, aluminum and many other varieties that have their own formulas and features. Such materials are useful in various fields, they contain various elements that affect the physical properties and characteristics of the operation of the metal.

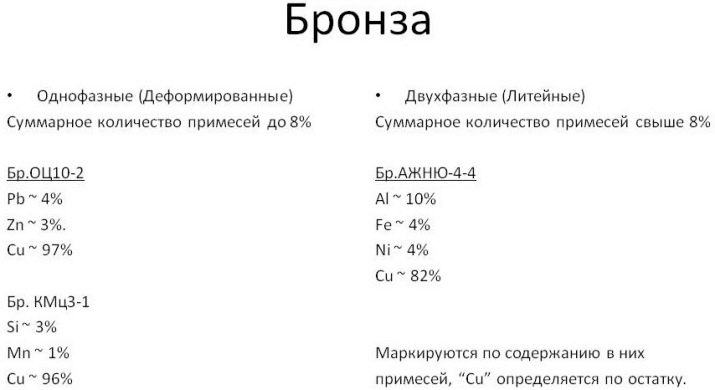

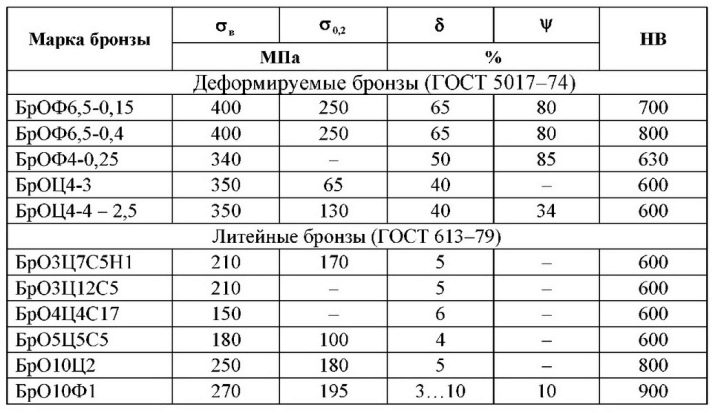

- Existing bronze alloys are divided into cast and deformable subspecies. That is, to solve "their" specific tasks, it is possible to obtain a metal that can easily be cold forged - the process of deformation at normal temperature values. It will also be possible to obtain an alloy that can be cast.

- A significant advantage is that high-quality castings from the alloy under consideration demonstrate the most insignificant shrinkage - only 0.5-1.5%. This property determines the wide distribution and demand for the material not only among professional sculptors, but also in the manufacture of special industrial machines and devices.

- Bronze refers to materials that can be used several times. The alloy absolutely calmly transfers further melting, if necessary. This procedure does not harm the material, does not adversely affect its properties.

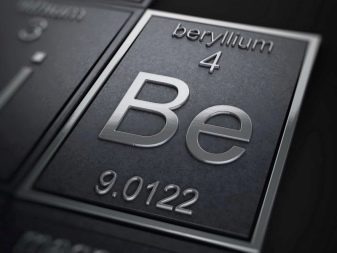

- One of the most important advantages of bronze is that it is safe and environmentally friendly. If potentially dangerous components, for example, beryllium, were involved in the production of such an alloy, then the finished product from this will still not be toxic. To date, not every material can boast of such important qualities.

- Bronze alloy has high corrosion resistance. Neither urban gas polluted air nor sea water can negatively affect it. Under the influence of such external factors, the material does not deteriorate, does not lose its former attractiveness. Most bronze acids are completely “not afraid” and are not exposed to their negative effects. That is why this material is often used for the production of special acid-resistant equipment.

- Bronze is another curious quality - it is resilient. The alloy is in many cases used for the manufacture of various high-precision spring parts that are designed for a long service life.

Despite the impressive list of benefits, the bronze alloy is still not without certain disadvantages. The main one can be called cost practical material. Copper, and even more so tin, are materials that are used in many situations, but they are expensive to obtain.

Other subspecies of the alloy in question, for example, the aluminum version, are several times cheaper, because in their composition more accessible raw materials are used as an alloying element.

The minuses of the bronze alloy include not its highest rates thermal conductivity. However, this distinguished feature was also able to find its application - for example, in the production of various bathroom accessories.

Main characteristics

The characteristics and properties of a bronze alloy depend on 2 main factors - composition and structure. As indicated above, the chemical composition of the material in question is developed in order for the alloy to obtain certain mechanical properties and performance characteristics. The most important of them can be called hardness, strength and ductility of the alloy. It is possible to correct and rebuild the first 2 parameters by changing the ratio of tin in the composition. So, its share in the content of the main material is related to the degree hardness and ductility.

The bronze has the greatest influence on the hardness and strength the amount of beryllium in the composition. Certain alloy grades in which the named element is provided may be more durable than stainless steel. To add ductility, the beryllium alloy previously goes through the hardening stage. An important role is played not by the quantitative values of the introduced substances, but by the severity of the properties that are planned to be obtained in the end.

That is, with an equal number of 2 different elements, one of them is able to change the properties and characteristics of the alloy to a greater extent than the second.

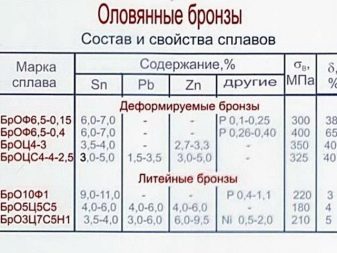

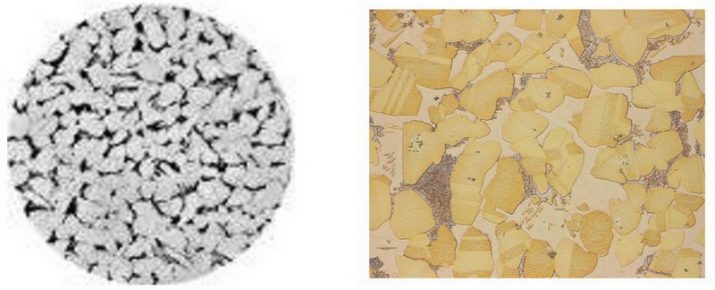

The structure of the bronze alloy is responsible for the accommodating ability of matter in relation to different elements. This feature can be considered in more detail on the example of an important component - tin. For example, a 1-phase structure has no more than 6-8% of the named element. If its indicators are exceeded by the amount of solubility limit (reaches 15%), then the 2nd phase of the solid solution can form.

Single phase raw materials are characterized by higher ductility. Biphasic the bronze alloy is more rigid, but at the same time more fragile. The specified technical characteristics affect the further use of the materials considered: for example, the raw materials of the first type are more suitable for forging, and two-phase options will be the best solution for further casting.

Each type of bronze alloy has its own distinctive features. Let's get acquainted with them by the example of injection tin material.

- The degree of density of the alloy depends on the percentage of tin - with its share of 8-4%, it will be from 8.6 to 9.1 kg / cu. cm.

- The melting temperature will depend on the composition of the alloy and can range from 880-1060 degrees Celsius.

- The level of thermal conductivity of the material in question can reach 0.098-0.2 cal / cm, which is a modest indicator.

- The electrical conductivity reaches 0.087-0.176 μOhm * m. This indicator is also small.

- The degree of corrosion in sea water is 0.04 mm / year. If the alloy is in an open air environment, then this value will be different and will be 0.002 mm / year.

If the metal has similar characteristics, users do not have to worry about it starting to rust quickly.

Species overview

Bronze alloy is divided into several different types. The classification of the material takes place according to several main characteristics. Let us dwell on each of them.

Chemical composition

Proceeding directly from the chemical composition of bronze, the following varieties are distinguished.

- Pewter. The material of this subspecies contains 3.5-7% tin. The alloy boasts high strength, reliability and elasticity after a preliminary pressure treatment. The material has excellent casting qualities. Shrinkage can reach 1% (as is the case with foundry iron).

The main disadvantage of this material is hidden in the appearance of microscopic pores during the crystallization of the casting.

- Tinless. This category includes such varieties of alloys in the chemical composition of which there is no expensive tin. Instead, they include more affordable and affordable materials.

- Aluminum. The most plastic material. Its casting properties are lower than that of expensive tin bronze, but there are no micropores in the composition. The composition includes nickel, phosphorus and iron - components that improve the properties of aluminum alloy.

- Silicon. High-strength subspecies of the material, resistant to corrosion, is electrically conductive. The material is not afraid of low or high temperatures, alkaline environment. In order for the metal to have higher strength characteristics, the chemical composition is additionally alloyed with manganese and processed by cold deformation.

- Beryl alloy can be heat treated using quenching and artificial aging. The main disadvantage of this type can be considered the high cost of beryllium.

Because of this, silicon bronze alloy is used exclusively in the production of special units, which should be characterized by high wear resistance and durability.

On processing

Bronze alloys are separated based on the types of processing.

- Deformable. In the production of bronze parts, such popular technologies as forging, broaching, cutting, and milling are used.

- Foundry. A separate type of bronze alloy. Parts that consist of this metal are made by metallurgy.

By structure

Different types of bronze alloys are also divided in their structure. The following options are distinguished.

- Single phase. The components present in such a metal in a solid solution form only one specific phase.

- Biphasic. Products are obtained by casting, because it is deformed solely under the influence of high temperature indicators. It is possible to obtain castings of the most complex and intricate configurations from a two-phase alloy.

Scope and labeling

There are currently several different grades of bronze. They differ from each other directly in composition, which determines the characteristics, parameters and scope of the alloy. To navigate more conveniently, a special marking system has been developed, which includes alphanumeric characters (reflect the first values in the names of chemical elements).

The numbers in the grades indicate the number of components provided in the alloy (in percentages). True, the volume of copper is usually not reflected in these designations.

This indicator is usually calculated as the difference between the total composition of bronze and the number of additional alloying elements.

Currently, bronze alloy is used in many fields. Check out their list.

- The alloy, in which there is only 2% tin, is perfect for forging at ordinary temperatures, as it has good ductility. Compositions in which the concentration of this element reached 15% were widely used in ancient times - many different objects were made from them.

- High-quality hardened bronze containing beryllium is often used in the manufacture of spring parts, springs or membranes.

- Material rich in aluminum is most often used in adverse conditions (chemical production, high humidity).

- Silicon and zinc alloys are viscous and suitable for the production of objects by casting.

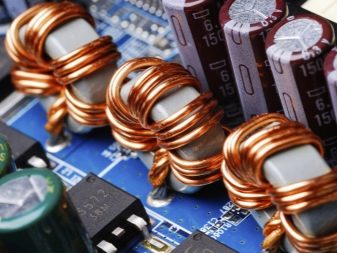

- The material in question is used for the production of various electrical equipment, since it does not magnetize.

- Baths, washbasins, plumbing devices, which are often used in home (and not only) conditions, are made of material that does not differ in thermal conductivity.

- Bronze alloy can also be used in the automotive or aircraft industries.

How to distinguish at home?

Bronze has quite different differences from other similar metals. There is nothing complicated in the art of "computing" this material. We will analyze how you can easily and simply distinguish bronze at home.

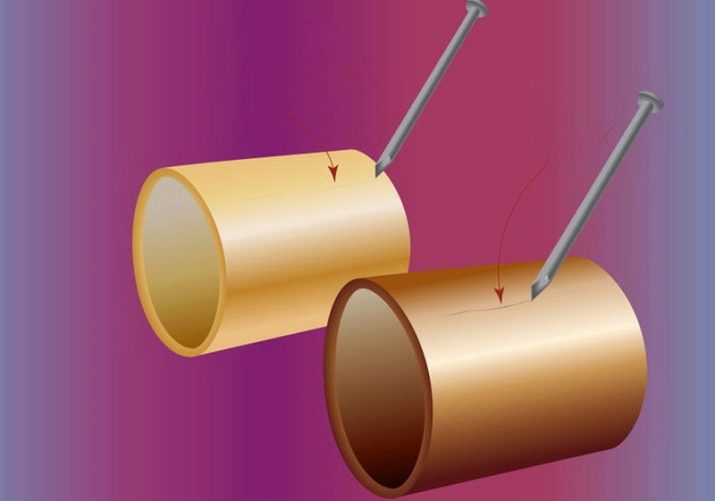

- Bronze differs from many other alloys in high strength and rigidity. Thus, the metal is easily distinguishable from copper or brass. It is enough to literally check the material “for a tooth” - there should not be any traces on the surface of the bronze alloy, as is the case with pressure.

- You can conduct an experiment with saline (200 g per 1 liter of water). A copper product after 10-15 minutes will acquire a more saturated and catchy shade than a bronze part.

- They resort to heating the metal to about 600 degrees Celsius (A similar temperature can be obtained using a special gas burner).If you bring the device, for example, to brass, a dark film of zinc oxide will appear on the material. On a bronze product it will not be visible.

- If you heat the brass, it will bend. If such an operation is carried out in relation to bronze, it will not change its properties and form. If there is a possibility and a sample of metal, you can try to melt it. The same brass will burn with a white flame, scattering snow-white flakes - in this way zinc burns out.

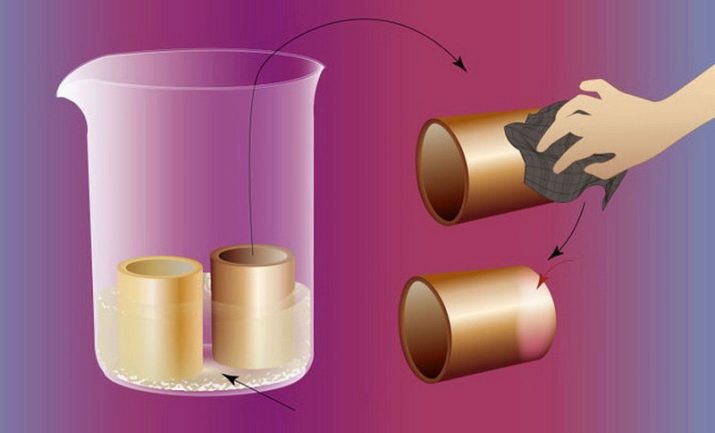

- You can distinguish bronze from brass in another reliable way.: Put a few shavings of each of the metals in separate tanks, and then pour in diluted nitric acid (1 part acid and 1 part water). Wait a while until most of the components have time to dissolve. Next, you need to warm the beakers and bring the solutions to a boiling state. 30 minutes you need to hold them over low heat. The liquid in which the pieces of brass are located will be transparent, and a white precipitate of tin will form in the vessel with bronze shavings.

How to care?

Products made from a bronze alloy need proper periodic maintenance. They should not be neglected. Let us consider in more detail how to properly care for such items.

- Noble bronze items look spectacular and attractive only if they are well-cleaned, well-groomed. You should regularly remove from the surface of objects all dusty accumulations and dirt. To do this, it is best to use a slightly dampened cloth. You do not need to rub products with all your strength - be careful.

- To keep the original varnish coating on bronze products as long as possible, you can periodically wash them with a mild soap solution. These actions will be necessary so that cracks or destruction of the varnish layer do not appear on the objects.

- If you are a big fan of things polished literally to a perfect shine, it is recommended to clean the bronze using specialized powders and reagents. A good reputation, for example, boasts a special cleaner for Trilon bronze.

- Having completed work on deep cleaning of bronze alloy products, it is advisable to polish the metal surface well. Dry wool fabric will do the job best.

- Sometimes, for cleaning bronze, dry tooth powder is used, previously diluted in water with the addition of ammonia. Need 1 cup of powder, 1 teaspoon of alcohol. It is advisable to use a stiff brush for cleaning.

- An ancient and traditional way of cleaning bronze is this option: the use of water in which legumes were previously cooked. Further cleaning is also carried out using a stiff brush. After that, a clean metal product should be rinsed once again and wiped clean with a dry cloth.

If you plan to use a rag to clean bronze, it is better to take flannel option. Particularly thoroughly and thoroughly it is required to clean places with folds and indentations, since it is here that dust and dirt accumulate most actively.

The products should be cleaned regularly so that excess inclusions do not accumulate on them.

About what bronze is and where it is used, see the next video.