Bakery stone is a very useful invention and is widely used for baking various dishes. Despite the fact that cooking technology with its help is only gaining popularity, the stone has already acquired a sufficient number of fans around the world, including in our country.

What it is?

Bakery stones are whole or stacked plates used for baking bread and baking other products at home. Baking, for the manufacture of which baking stone is used, in terms of taste it becomes as close as possible to dishes from tandoor or a Russian oven.

The secret to this success is quite simple and is as follows: a stone heated to high temperature from the first seconds warms up the yeast dough to its entire thickness, as a result of which the bread manages to rise as much as possible before a crust forms on top.

The dough does not crack with this technology, which is explained by the death of yeast at +60 degrees and the ability of the stone to maintain a given temperature until the crust forms. As a result, the bread does not break and it turns out perfectly smooth and baked. Even the cuts on the loafs only open slightly and do not tear.

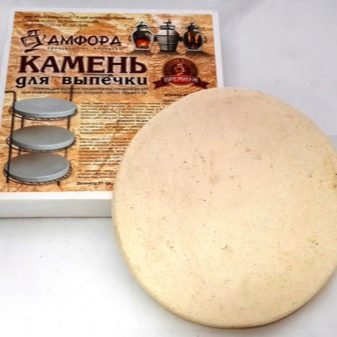

Baking plates can be made in the shape of a circle, square and rectangle. Round are mainly used for making pizza, while the last two options are universal and suitable for baking any dishes.

The thickness of the products varies from 1.5 to 3 cm, which depends on the manufacturer and material of manufacture.For example, Chinese models often have a lower cost, but they are too thin and quickly crack. There are stones and are thicker than 3 cm, but their use is not too rational in terms of energy or gas consumption.

Thick specimens require a longer warm-up, which is an average of 30 minutes for every 1 cm of thickness. A thickness of 2-2.5 cm is considered optimal. Such models quickly warm up and give off their heat for a long time.

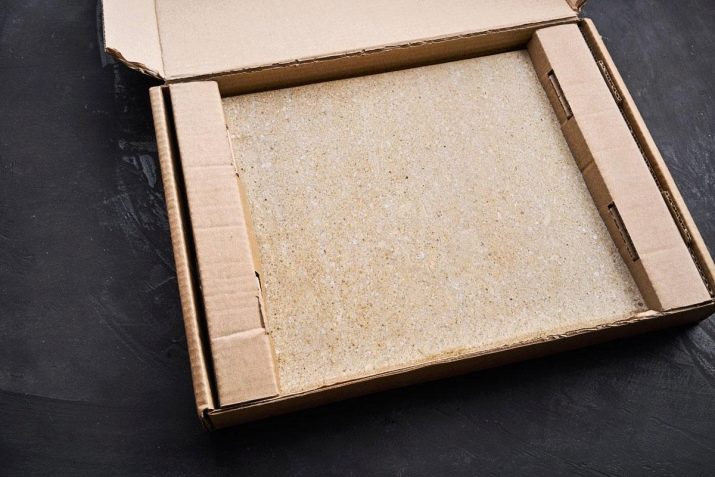

The sizes of stones are also very diverse, but the most convenient are dimensions of 30x45 cm. If the dimensions of the oven allow, then such products are considered the most optimal option and allow you to bake three baguettes and two oblong loaves of bread at the same time. As for the design, one-piece models are slightly more expensive than typesetting options.

The latter are usually several tiles with a ribbed bottom surface with a thickness of 1.5 to 2 cm. Their disadvantage is excessive fragility, and the advantages include low cost and the ability to use in small ovens.

The steadily growing consumer demand for baking stones is due to such indisputable advantages as the possibility of baking without the use of oil, the uniformity of baking the dough, the full environmental friendliness of the process and the formation of a crispy appetizing crust.

The latter can be achieved due to the property of the stone to absorb moisture from the dough, giving in return a large amount of heat. The environmentally friendly use of models is due to the presence in the composition of the stone exclusively natural componentsthat do not enter into dangerous chemical reactions with products, as happens during frying in a pan with the use of oils.

In addition, when the oven is preheated, the stone is very hot, which leads to the creation of the effect of a hearth furnace inside the oven. Thanks to this, baking time is significantly reduced, and muffin turns out magnificent, airy and very fragrant. The advantages include ease of handling and easy care. Products do not need to use cleaning productsWash perfectly with warm water and a clean cloth, and can also be placed in the dishwasher.

Moreover, most baking stones are very strong and have a compressive strength of 50 MPa, which corresponds to 50 kg of weight per 1 cm². Models perfectly withstand temperatures up to +1500 degrees and are not afraid of its differences.

What is it needed for?

Baking stone is a real salvation for housewives who use ovens with uneven heating. In such ovens, one side of the baked goods often burns, while the other remains almost damp. Due to the presence of microscopic pores, a hot stone is able to maintain the desired temperature inside the oven for a long time without leading to its increase.

As a result, the dough is baked very evenly, the bottom does not burn, and a golden crust forms on top. Moreover, models are capable of not only maintaining a certain temperature, but also leveling it in different parts of the oven. Baking stone is perfect for making ruddy bread, pizza, muffin, tortillas, pita bread and baguettes, as well as for baking meat, fish and potatoes.

What materials are stones made of?

As a material for the manufacture of baking plates, clay and natural minerals are used.

Clay

Clay stones or slabs possess more porous structure compared to natural stone and much better absorb moisture. Products are absolutely safe for human health, which is due to the absence of toxic impurities and toxic components in their composition. Clay does not react with products, guaranteeing the absolute naturalness and purity of baked dishes.

The only drawback is not too high resistance to temperature extremes, which is why the service life of clay specimens is much inferior to the life of models made of natural stone. Clay slabs can be glazed or be without it.

Their surface is usually smooth, but in recent years products with a raised bottom have begun to appear, contributing to an improvement in the circulation of hot flows. There are models with imitation of small stones, on which it is especially convenient to bake bread.

For the manufacture of baking plates, two types of clay are used.

- Red. It is notable for its low price, low weight and very fast heating. The disadvantages of red clay products include fragility and a high probability of a split when cold water enters a hot surface. In this regard, it is not recommended to spray the concoction when using ceramic models.

- Fireclay. Products made from chamotte clay, characterized by high strength and long service life. Such stones are often made manually, which in the end greatly increases their cost. Stamped factory plates are much cheaper and are characterized by lighter shades. Moreover, with constant use, the clay darkens noticeably, which is a natural process and does not in any way affect the quality of the dishes and the durability of the products.

The only drawback of fireclay patterns is lower porosity, which can adversely affect the quality of yeast muffin and bread.

A natural stone

Refractory minerals such as sandstone and quartzite. They are characterized by high porosity and are able to quickly accumulate and give off heat for a very long time. In addition, sandstone is a very durable stone and tolerates cooling and heating well. Models from this mineral usually have a thickness of 1 cm, are characterized by a wide palette of shades, including white, fawn and green with gray stains of color.

Indian quartzite is a "relative" of sandstone, but in its density and durability significantly exceeds it. Both materials completely harmless and do not emit any odor or harmful substances when heated. The disadvantages of both materials include high cost products made from them, due to the difficulties of transportation and processing of minerals.

However, models from smoother and harder minerals are often found - granite, marble and steatitehaving both definite pluses and significant minuses. So, marble stones have a very attractive appearance and have the right number of pores, but they do not tolerate temperature changes very well and are expensive.

Granite stones hold heat for a very long time, but due to volcanic origin, they can emit a small amount of harmful substances when heated. However, their concentration is not so critical, many professional bakers use stones exclusively from this mineral. Steatite or soapstone tends to heat up very quickly and heat dissipates slowly, but differs in very dense structure, weighs quite a lot and has no pores.

Natural materials are very durable, they tolerate conditions of high temperatures and high humidity. However, many of them may turn out to be toxic or change the taste of baked muffin, therefore, the independent selection of a stone for the oven is prohibited, use should be made exclusively of minerals allowed for use.

Manufacturers Overview

The modern market of kitchen accessories offers bakery stones in a large assortment. Among manufacturers there are both small, little-known companies, and large companies that have an excellent reputation and provide consumers with durable and high-quality products. These include LLC "Bakery Stone" from St. Petersburg, producing models under the brand name "Gourmet".

The company's products are distinguished by high working qualities and reasonable price. For example, the most budgetary model made of volcanic rock can be purchased for just 1,650 rubles. The product is available in sizes 38x28x1 cm and weighs 2.4 kg.

Due to its compact size, the stone is perfect for conventional stoves with gas or electricity stoves. You can cook on the stones "Gourmet" anything, from buns and pies to stuffed vegetables and meat dishes.

No less well-known manufacturer is the company Weberproducing round and rectangular baking stones. Among the assortment, one can note a round-shaped model intended for the manufacture of pizza and costing 4,999 rubles. The product is equipped with comfortable handles and a non-stick coating, allowing to cook with a minimum amount of oil or without it.

How to choose?

When choosing a baking plate, you should first focus on its thickness. For unprofessional use it is better to buy a product with a thickness of 1.5-2 cm, which will allow you to bake bakery products on it, as well as prepare meat, fish and other dishes.

If the stone is purchased exclusively for pizza, then you can opt for a round model, but if you intend to use it for cooking various dishes, then it is more rational to purchase a rectangular version. As for the size of the stone, then its dimensions should be 3-4 cm less than the internal area of the oven. This will provide the necessary clearance near the walls and will contribute to the proper circulation of hot air.

An important criterion for choosing a baking plate is its porosity. So, if the model is purchased for baking bread and baking, then it is desirable that it has a more porous surface, but sweet pastries, cheesecakes and meat rolls can be baked on denser copies. For the manufacture of pizza it is better to choose a product 1-1.5 cm thick, which will contribute to a more rapid heating of the material and significantly reduce the cooking time.

In addition to pizza, on thin plates you can bake pita bread, khachapuri and products from unleavened or puff pastry. When choosing a baking stone, you should know that more durable are models equipped with angular or longitudinal legs. The presence of an air gap between the baking sheet and the baking plate eliminates the thermal shock of the material, which significantly extends the life of the product.

In addition, before purchasing, you must familiarize yourself with the certificate of conformity, confirming the purity of raw materials and the absence of harmful impurities in the composition of the stone.

Operation and maintenance

In order for the bakery stove to serve for a very long time, a number of simple rules must be observed.

- Before you start using a new stone, it is necessary to put it in the oven and calcine at +250 degrees. The calcination time depends on the thickness of the model, on average it is 30 minutes. /cm. After the stone has calcined, the oven should be turned off and opened, allowing the mineral to cool naturally.

- Use the stone should be "dry", treating it with vegetable oil is not recommended. Otherwise, the oil film will tighten the pores, heat transfer may be disrupted. If necessary, the surface of the stone can be covered with flour or covered with parchment paper, and meat and fish can be cooked wrapped in foil.

- In no case should stones be subjected to sharp temperature drops, removing from the stove and placing under a stream of cold water. The product should cool gradually, otherwise it will become brittle and will quickly crack. The same applies to its heating: in no case should you put a cold stone in an already preheated oven. It should be heated and cooled only with the oven. In addition, it is also impossible to put wet stone in a preheated oven.

- Between the oven and the bottom of the oven There must be an air gap, so do not put the product on the bottom. If necessary, place it on the grill and arrange it at the lowest possible level.

- For laying out bread you must use a special shovel, which often comes with a stone.

As for the care of the baking stove, it includes regular rubbing of clay products with a damp cloth and washing models made of natural stone in warm water. Cleaning models using household cleaning products is prohibited. For heavy soiling, a soft brush is allowed.

See how to use baking stone correctly in the next video.