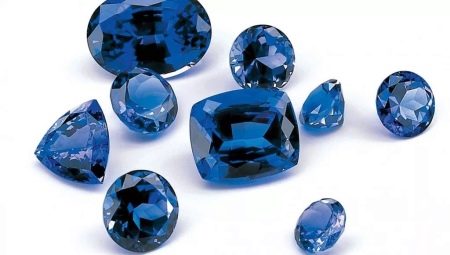

Synthetic sapphires are widely distributed in the jewelry market. Natural stone is considered precious and has a high price. An alternative option also looks noble in products, and in terms of aesthetic characteristics it is not much inferior to the first option.

What it is?

Natural gem forms in a specific environment for millions of years. The price for it is sky-high, but demand is still good.

Natural minerals are formed in the earth's crust due to some geological operations that are interconnected in time and space.

Water, high temperature and high pressure form ore veins. They serve as clusters of various crystals.. In sapphire deposits there are also liquid gases that have been circulating in enclosed spaces for many years.

In the laboratories for creating nanominerals, scientists have recreated natural conditions. But for the grown crystal to be of a decent size, it takes several months. Nano sapphires grow faster, and therefore cheaper than natural counterparts. The cost of artificial stones is lower, but not enough to compare them with ordinary glass. The purity and color depth of artificial crystals is better than that of genuine minerals. Hydrothermal sapphire does not require additional refinement, like a stone with genuine properties. These methods, by the way, are expensive and require additional investment.

Artificial sapphire means a kind of corundum. It is also the basis for rubies and emeralds. Sapphires have a blue color due to titanium and iron. Heated beryl is also involved in the synthesis. Given the conditions of production, we can say that synthetic stone is not grown, but boiled. At the base of one of the mixtures is aluminum oxide, which looks like an ordinary white substance. It will turn into sapphire only at a temperature of 2200 degrees Celsius. The crystallization rate of artificial sapphires is 4 mm per hour. Big crystals need a lot of time. Later, if necessary, they are cut into pieces and processed, giving similarities with natural deposits.

Synthetic sapphire production

The main method for the production of artificial crystals requires a special Verneuil furnace. It has been used for decades. According to this method, aluminum oxide is melted in a flame of a hydrogen-oxygen burner. Verneuil’s furnace makes liquid drops. Upon gradual cooling, they form a crystal. In addition to sapphire, this technology is also suitable for the production of ruby, as well as other precious stones. The difference is the addition of impurities of various metal oxides, which give a suitable color.

Technology invented at the beginning of the 20th century is still in use. It has undergone only minor changes, allowing you to deploy the process to the conditions of large-scale production.

The ubiquity of technology began around 1932, and especially intensified during the Second World War. In production, a mixture of starting materials with specified physical and chemical qualities is used. Homogeneous components loaded into the unit are called a “charge”.

The size of the microparticles in the mixture is from 1 to 20 microns. A portion of powdered substances is poured into a hopper in which there are openings. Through them, substances enter the furnace where hydrogen is burned. The mixture melts and builds up the seed crystal. The seed tank rotates, providing uniform growth and warming. As it grows, the seed is lower, and the upper part is transformed into faces.

The form in which the charge resembles an expanding cone. Depending on the consumption of the base material, long crystals are obtained in it. In addition to the flow rate, such parameters as gas supply and rotation speed, heating quality are important. The method has characteristic advantages:

- the ability to control crystal growth visually;

- combustion temperature is automatically adjusted;

- fluxes and expensive crucibles are absent in the finished material.

The disadvantages of the method:

- due to the high temperature, internal stresses appear in the crystal;

- due to a violation of system rules during the preparation of the charge, volatile substances can escape, and subsequent restoration of the process is impossible.

Post-Growth Treatment

The resulting shape and size of the crystals usually does not correspond much to the parameters of the manufactured parts. Therefore, processing of materials is almost always necessary. For machining, conventional turning, milling or drilling machines are not used. Products are fragile, so only abrasives are possible in operation. Diamond discs or grinders, suspensions or special pastes can be used.

Typically, abrasive particles are pressed into the surface of the material to be processed. Microcracks are formed in it, which during the process move inland. Further actions lead to a whole network of cracks. They close, causing chipping of individual sections. They are removed in layers from the surface, giving the product the desired shape.

Abrasive materials intended for processing are not in vain separated by hardness.

Abrasive ability, which is expressed by mechanical or chemical resistance, depends on this property.

Experts choose the right abrasive according to the Mohs mineralogical scale. By the fundamental differences of minerals, diamond corresponds to tenth grade, and corundum to ninth. For processing sapphires, special grinders or suspensions are suitable.

Grinders are cast iron, glass, steel, copper or brass parts with abrasive micropowders. Granularity of micropowders can be from M14 to M5. After polishing the grown crystal, it needs polishing. For this process, an abrasive slurry is selected, which is rubbed into the surface until complete uniform distribution. Polishing is carried out in two stages, for which different abrasives with a coarse or fine grain size are selected.

What is the difference from natural?

Artificial corundum, like natural deposits, is blue or dark blue. A laboratory counterpart is a popular imitation that can be difficult to distinguish. Specialists grow a synthetic product without chips and damage, and jewelers like this quality. You can check the product by external indicators:

- an artificial mineral has a more flawless and pure shade;

- there are practically no internal defects in it;

- liquid formations, if any, are correctly spherical in shape, while in natural deposition there are practically none;

- if you carefully consider genuine and synthetic sapphires, they can be distinguished precisely by quality, and natural stones necessarily contain various natural inclusions that are not in the laboratory stone.

Moreover, the chemical and physical properties of both species are completely similar. Specialists distinguish the nuances that are hidden in the wrong structure of growth. The hardness of genuine and laboratory stone is different.

To check a sapphire-like stone, special settings are needed, for example, a refractometer, which measures the parameters of light refraction.

Genuine minerals give out 1,762 - 1,778.

Another way involves the use of a special fluid. Monobromonaphthalene is placed in a container, which is installed on a background of white paper. Visible curved colored stripes indicate the artificial origin of the stone. Shortwave ultraviolet can also be used. Under its action, a real stone will not change color. The grown sample will shine white or off-green. The glow may be red. It depends on the used impurities in the composition of the charge.

In connection with the development of technologies for growing artificial sapphires, it becomes difficult to distinguish them with improvised methods. Full conclusions can only be drawn by professionals who have the appropriate skills. Knowledge of certain properties of a stone can also help.

The properties

Artificial sapphire has internal properties identical to natural stone. In addition to the jewelry industry, it is widely used in watchmaking or as a semiconductor material. All semiconductors are characterized by high sensitivity of electrophysical qualities. Semiconductors are actively used in circuits for various equipment. Almost all modern integrated circuits contain semiconductor elements.

Crystalline substances have the ability to conduct electric current, but with temperature changes, the action of light rays, the presence of impurities of other substances. Scopes of semiconductors are extensive: radio engineering, optical electronics. In alternative medicine, sapphire is known as an antidote to many toxic substances. From ancient times, the healing qualities of sapphire have been used to acquire pure thoughts, spiritual peace and balance, and to gain selflessness.

Selection and care

One of the most difficult for laboratory reproduction of stones is considered cornflower blue sapphire. Creating this shade is impossible without thorough training. Technical data must be observed to the exact extent. Natural stone of a similar shade is available only in India. In this country, he is a ritual and ritual amulet.He is chosen for the treatment of heart failure, gaining psychological stability. If you keep the stone in the house, then well-being will surely come, and the owner of the house will have leadership. The most beautiful natural sapphire samples are stored in special funds of such countries as:

- Thailand - 16 kg;

- Sri Lanka - 18 kg;

- USA - 15 kg.

In Russia, there is cornflower sapphire made in the 19th century; it is stored in the country's diamond fund. The stone is incredible strength and durability. At home, sapphire jewelry requires additional care. Regular humidity, exposure to direct sunlight and dust are harmful to jewelry. Products can be improved by regular cleaning. Normal soap solutions or shower gels are suitable for soaking. The products used must then be washed off with cold water.

In jewelry stores, you can find special care products for precious stones. They are usually in the form of sprays or disposable wipes. The funds are expensive, so their use is liquid with severe contamination of jewelry. Since sapphire rarely loses its original shine, it is enough to use ordinary household cleaners that every housewife will find.

Watch the video to learn how to cultivate artificial sapphires.