Gold belongs to precious metals and is in great demand now, as it was many years ago. Gold jewelry complement their style people regardless of age and gender. You can get this precious metal with your own hands at home, using special technology - refining.

What it is?

Gold refining is a chemical process by which metal is purified from various impurities. After this procedure, the precious metal is obtained in a pure, processed form. This type of event can be carried out not only in a specially equipped laboratory, but also at home. Gold mining in this way is considered toxic and dangerous, so when it is carried out, all safety precautions should be taken into account. Obtaining almost pure precious metal is possible from raw materials that contain this element.

This includes a radio component, a board from TV and computer equipment, radio tubes and types of gold-plated objects, as well as relays, a transistor, a diode, and much more.

Ways

There are several ways to carry out refining.

Chemical

Often people use the chemical method of gold extraction. This method in other words is called wet and can occur when interacting with zinc, copper, ferric chloride, tin.

Zinc Procedure

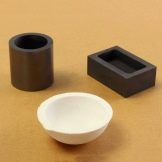

Using this method, gold with scrap having a different sample is purified. It is also worth remembering that in this case, the presence of more than 50% of the noble metal is not necessary. To carry out the work, it is worth preparing zinc in an amount equal to the volume of the noble metal. Before you start melting, the metal should be dried, and the crucible should be heated using an electric stove. Before heating, the crucible must be dried, since wet often bursts. After that, a drill is added to the crucible and melted. It is worth remembering that in this case, the bora must be dispersed throughout the depths of the crucible. This event can be easily carried out using a burner. In this case, the drill is used to prevent the formation of an oxide film.

The next step is to transfer the metal into the crucible and heat it until it turns red. After the gold has melted, a ball will appear in the storm, which means that it is time to add zinc, constantly heating the mixture. The metal should look like small pieces, each of which should be introduced after the previous melts. After making all the zinc, it is worth mixing the contents of the container with a spoke. Next, the metal should be removed and, after cooling, sent to water. The next step in the purification of gold will be its grinding into a powdered state. After this, you need to prepare nitric acid, the volume of which should exceed 10 times gold.

This procedure can be carried out in a mortar.

All subsequent refining procedures are done by putting on a protective mask and in the fresh air, since a large amount of dangerous gases is released. The powder should be poured into a glass flask and installed on an electric stove. Pour a third fraction of acid into the container and wait for the reaction to subside. After this, add nitric acid twice more and boil the mixture.

It is worthwhile to conduct heating until the steam leaving the flask is white. Then the precipitate must be washed and cold water added to it. Next, shake the mixture and after the flakes settle, drain the liquid. Such measures should be repeated until the liquid becomes clear. The sediment, which is located at the bottom - this will be pure gold. After drying, the noble metal can be sent for melting

Copper refining

This method is similar to the previous one, only at the initial stage, copper needs 2 times more than scrap. In a needle with a molten borax, copper is initially melted, and then gold. At the end of the melting of the metal, it should be separated from the borax and repeatedly rolled in rollers. Before each rolling procedure, the metal should be heated. When gold and copper begin to be cut into pieces, it can be evaporated in nitric acid, as in the previous case.

Chlorine Tin Refining

In the presence of dissolved gold, a noble metal can be obtained from it by reaction with chlorine tin. This method has the following characteristics: ease of implementation; minimal harm that can be done in the course of a person; as a result of the procedures, pure gold is obtained. It is worth adding 1 part of water and hydrochloric acid to the chlorine tin powder. In the presence of gold in the solution, an instant reaction can be noticed. In this case, the solution is left for a day. During this time, gold forms in the form of a precipitate at the bottom of the tank.

Electrochemical

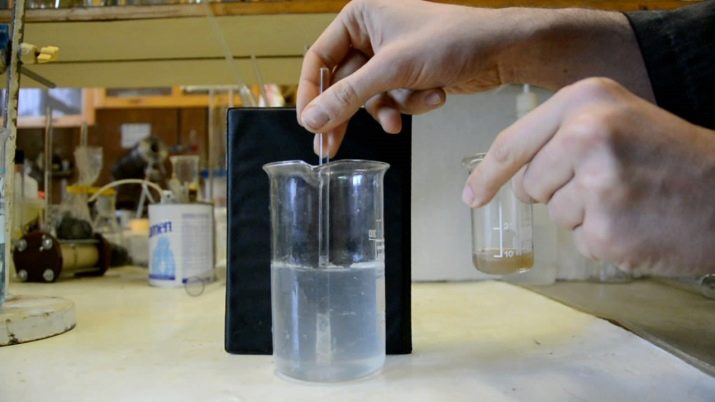

The refining of gold by the electrochemical method is the most common at present, it is used on a large scale. The reason for this demand can be called the simplicity and effectiveness of the method - electrolysis. To use this refining option, first you need to prepare the container and fill it with gold chloride in the form of a solution with hydrochloric acid. In order to obtain 999.9 as a result of the sample operation, the bath must be connected to the power supply. The result of an experiment is usually a precipitate of pure gold. In industry, pure gold cathodes are used, but at home, a substance with iron and lead is applicable.

Home refining

The main method of extracting pure gold from a mixture of radio components is chemical refining, which can be done at home.You can make the procedure at home "royal vodka" by passing through the filter and recovery. The simplest and most common methods include the following.

Iodine Cleaning

To etch gold from a radio component, you can use Lugol's pharmacy solution, which has the form of a combination of iodine and potassium iodide. During the reaction, complex anions appear in which the gold molecule is contained. To increase the reaction rate, some chemists advise adding sulfuric or nitric acid. The dissolution procedure can last several days. Various methods can be used to precipitate a noble metal.

"White"

The composition of the popular inexpensive household bleach contains a large amount of sodium hypochloride. In this substance there is a fraction of perchloric acid, so chlorine is isolated from it. The latter is used to dissolve the noble metal and the formation of gold chloride. At the end of this procedure, sodium bisulfate is introduced into the solution. When the reaction is completed, at the bottom of the vessel you can find particles of gray color, which are gold. After remelting, the noble metal acquires its natural color. The second use of whiteness is to mix it with table salt and battery electrolyte, which are presented in the form of an acid.

As a result of the experiment, it is possible to obtain hypochlorous acid, which dissolves gold. Further, the recovery process is carried out.

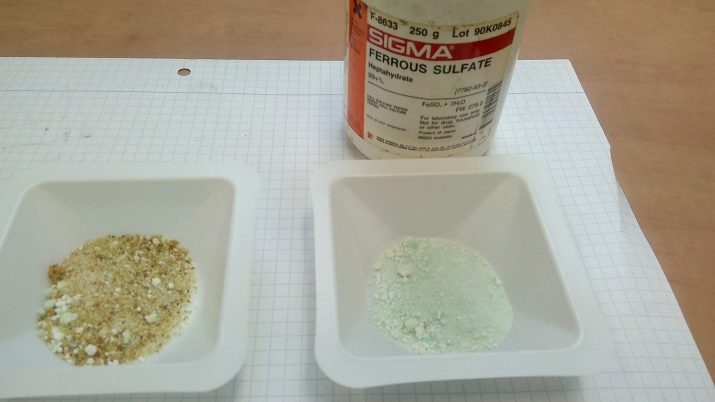

Hydrogen peroxide

It is possible to extract gold from a radio component using hydrogen peroxide at home. Perhydrol reacts with acid, after which the noble metal dissolves. For this purpose, the gold-containing part is poured with peroxide acid. As a result of the experiment, the formation of hydrochloric acid occurs, which subsequently can decompose into components. To carry out the decomposition procedure, the use of a thermal method will be required. A burner will need to be directed to the substance - its blue flame. The process of reducing a noble metal requires the use of iron sulfate.

Refining with “royal vodka”

To extract gold from a microcircuit or radio components, it is considered appropriate to use "royal vodka". The refining process consists of the following stages:

- mechanical grinding of components, separation of parts containing gold;

- the elimination of organic type compounds by burning or piercing;

- opening a window for good ventilation of the room;

- preparation of a vessel from borosilicate glass;

- placing the blanks in a container, namely 3 parts of hydrochloric acid, 1 part of nitric acid, while the introduction should be carried out gradually, in small portions, about 3 grams at a time (for 100 g of raw materials it is worth preparing 0.5 liters of “royal vodka”);

- heating the solution and gradually adding nitric acid to it;

- verification of the presence of noble metal with tin chloride.

Further, to restore gold, you can use perhydrol, iron sulfate, oxalic acid or hydrazine sulfate.

Zinc Refining

In addition to aqua regia, refining can be carried out with the participation of zinc. Despite the complexity of this procedure, high-quality gold can be obtained as a result. For work, it is worth preparing tweezers with high strength, a crucible, a steel spoke, a melting device, a titanium rod, a stove and a heat-resistant flask. First you need to heat and calcine the crucible in which the gold is. Then add borax and a titanium wand. After adding pieces of zinc one at a time, however, it is worth remembering that a new one is introduced after the previous one is melted.

The prepared mixture will be required for the subsequent reaction of gold with "royal vodka". In this situation, zinc plays the role of baking powder.Impurities of base precious metal are not able to react to acid, for their exit from the alloy it is worthwhile to mix them with zinc. The resulting material should be covered with a cloth, as well as chopped with a mortar. The next step is to pour the mixture into the flask and move it onto the stove.

After all of the above procedures, add “royal vodka” in a volume of not more than 200 grams to the flask.

As a result, a precipitate should form, which should be washed repeatedly with cold water. After 2-3 washings are carried out, it is worth sending a little water in the flask and pour it, along with the rest of the contents, into gauze. Borax should be poured on top. Next, the crucible should be covered with a cap and transferred to the tile. When borax and gauze are stuck, you can begin to melt gold from the remaining material. To purify the obtained substance from borax, it is possible to boil in a solution that is prepared from such ingredients:

- 0.5 liters of water;

- 10 grams of nitric acid;

- 20 grams of hydrochloric acid.

In the prepared solution, the gold ingot is boiled for about 5 minutes, after which it is washed in cold water and cooled. Carrying out gold refining at home is not an easy, but cheap job, as its cost will be much lower than carrying out in laboratory conditions. During the procedure for the selection of precious metal, it is worthwhile to carefully follow the instructions and not violate safety rules. Experts recommend wearing protective suits and masks to avoid negative health effects.

You can watch how to make gold refining in the next video.