For home needlewomen, a knitting machine is an indispensable thing, it allows you to quickly and efficiently make any knitted fabric at home. This device can be called universal, since almost everything can be connected on it - from the simplest scarfs to complex models such as coats.

The very first knitting machines were created a very long time ago - in the 15th century. Then they were used to make seamless stockings. Today, knitting technology has improved significantly. We will talk about how these devices work, how to choose a suitable model and how to operate the unit in our article.

Device

Knitting - this is the perfect way to provide yourself and your family members with warm clothes. Our grandmothers and mothers knitted on their hands, but for many this business is substituted for being too complicated and very time-consuming. That is why such a device as a knitting machine was created. The process of knitting on it is fast and does not require much physical effort, if you wish, you can even turn this hobby into an additional source of income.

The knitting machine is a design that allows you to quickly and easily create knitwear with a different pattern. Unlike hand knitting, on a typewriter the web will come out much smoother. Among the other advantages of the device can be identified:

- speed of work;

- perfectly even rows;

- the ability to simply and quickly make any openwork pattern.

The main elements of any knitting machine are:

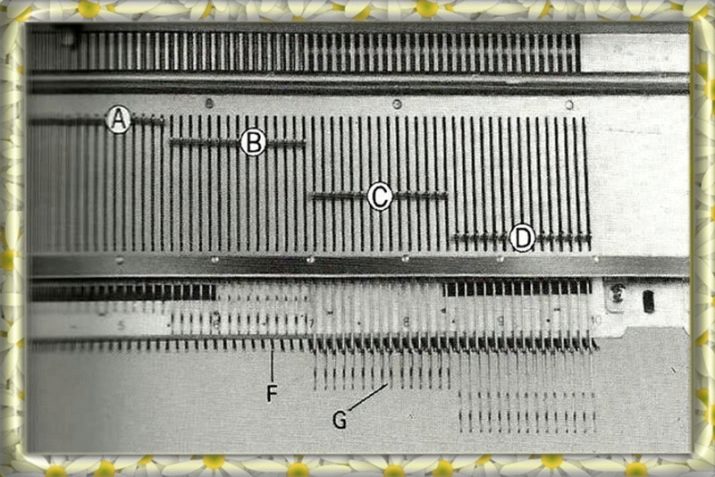

- Fontura (needle bar) - represents the basis of the mechanism;

- carriage - one of the leading mechanisms of the machine, which easily moves along a number of needles and is used to create loops. This device has a special knitting density control.

Principle of operation

The main design element of the knitting machine are needles. They are entrusted with the task of forming the canvas. They have 4 functional positions:

- ZNP (back inoperative position) - in this case, the heels of the needle are bent back to the axis;

- PNP (front inoperative position) - the needles are removed from the working position, while the loops remain on the needles;

- RP (working position) - is used in the process of knitting a flat cloth;

- PRP (front working position) - allows you to create openwork patterns.

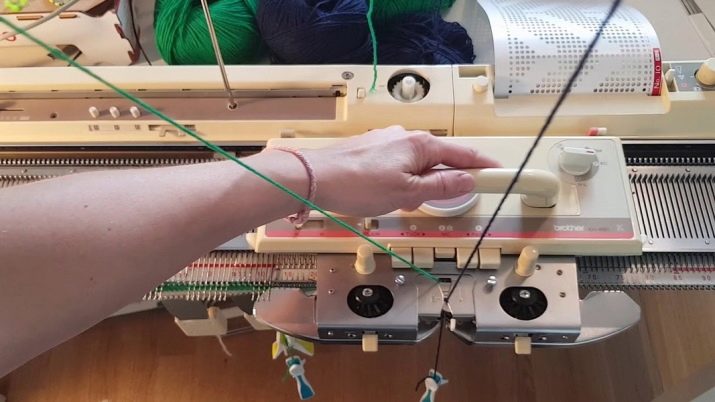

The main work of knitting is assigned to the carriage. This element has a built-in web strength regulator.

Work on such a device is carried out by moving along a row of needles on which the threads are strung. Each time when moving it, a new row of loops is formed, thus the canvas is obtained. The pattern directly depends on the location of the needles and the presence of yarn on them.

Kinds

There are several types of knitting machines. They differ in their purpose and functionality. Models intended for domestic use, in most cases, provide single-band knitting, which leads to the need for additional seams.

Depending on the number of needle beds, aggregates are divided into two categories.

- Single-loop - This is the most common and easy option that allows you to knit simple patterns. This device has some limitations, in particular, it cannot form a circular canvas, and also allows you to perform a fairly limited number of patterns.

- Two-circuit - professional category machines, they are much more expensive and more difficult to operate, but at the same time the number of their functions is much larger. In particular, on such machines you can make many of the most interesting ornaments and even perform colored patterns.

Knitting machines may vary depending on the way you control the needles.

Hand held

Any hand knitting machine is essentially a simple mechanical design, patterns in which are formed manually. Such models are the most compact and lightweight, the knitting speed on them is ten times faster than on knitting needles.

Hand-knitting machines belong to the budget segment, therefore most often they are used by beginner needlewomen for knitting at home.

Mechanical

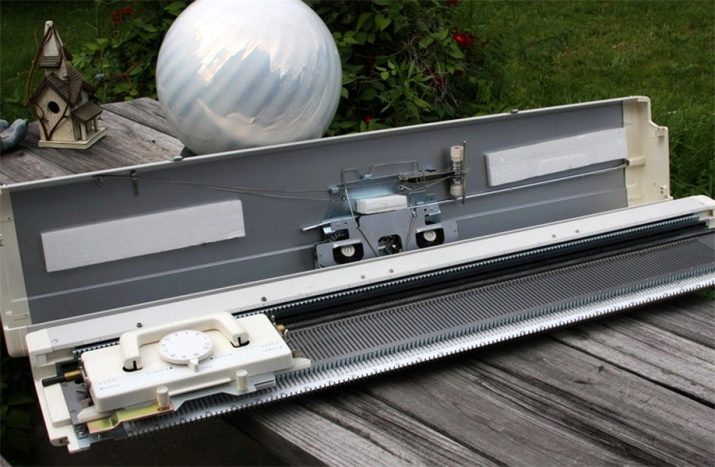

Mechanical knitting machines are also called punch cards. Such designs are many times superior to manual ones, but at the same time they are much inferior to electronic models. A characteristic feature of the cars is the presence of a small plate (punch card) of a flat shape with holes in the form of the planned pattern, which will subsequently be transferred to the knitted fabric. By changing the location of the panel, you can create complex weaves - the user can only move the carriage from right to left and vice versa. Most often, these methods of knitting are used for socks or scarves.

Defining a punch card machine is simple: as a rule, a small stand is provided on the side or in the center, which is somewhat reminiscent of a music stand for musicians. It is there that the card is inserted, it will later be read by the complex mechanism built into the machine.

Electronic

The most convenient option for the homemaker will be an electronic knitting machine. In such models, the movement of the needles is controlled using connected computer software. Automatic counting of knitting lines is provided both by a manual counter installed on the machine itself, and using the help of a program installed on a computer or laptop. In the course of work, it is very important to control the data of both counters, since in the event of a marriage they will not coincide with each other.

It should be noted that The software needed to control an automatic knitting machine is rather weak from the point of view of technology - the device can even be connected to the oldest PC with a minimum set of technical capabilities.

If you connect the typewriter to the laptop, make sure that it is placed separately from the typewriter. The fact is that when the carriage moves, vibration appears, as a result of which the laptop can simply fall off the table. If you use a desktop computer, then you should not worry - it is much more stable.

Externally, it is not difficult to determine a knitting machine that works on electronic control, since a colored wire passes from the carriage, similar to that used to connect any stationary phone.

In recent years, new, more advanced electronic models have appeared that do not require a computer connection. Such devices are much more convenient in operation, since they do not require additional space for a computer. And as for the set of options, such devices are identical to those models that are controlled through a third-party computer.

Classes

Knitting machines vary in class. For domestic use, it is recommended to use models 3, 5 and 7 classes.

The constructions of the third class work with thickened needles placed 6.5–9 mm apart and allow the manufacture of dense yarn with parameters of 100 g per 200 m. Such machines are optimal for knitting warm things that are needed in late autumn and winter.

Machines of the fifth class are universal equipment. They are inserted needles of medium thickness, the removal between them varies from 4.5 to 9.5 mm. The unit works with yarn with parameters of 100 g per 500 m. Similar plants can be purchased for knitting a wide variety of products that can be worn not only in winter, but also in the off-season.

Designs of the seventh class are designed to work with thin needles, the removal between which varies between 2.8-3.6 mm. Their equipment allows you to work with a fairly thin yarn with parameters of 100 g per 600 m.

On machines of class 7, you can only knit light clothing, you can’t make a warm sweater.

Manufacturers

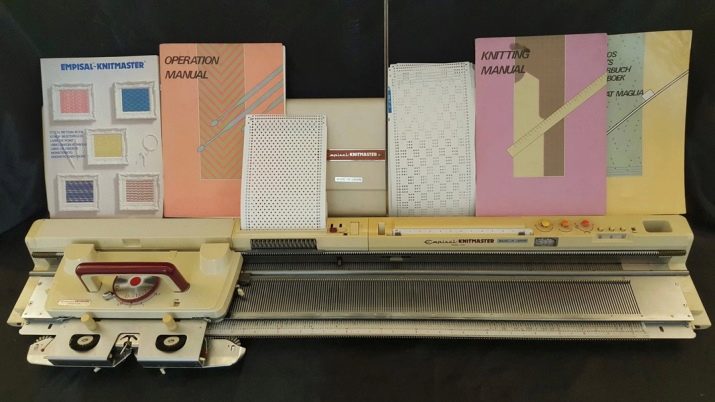

The most popular are knitting machines of brands Knitmaster, Veritas Creative, as well as Kakadu and the Russian brand Ivushka. Among the market segment leaders, Silver Reed products have been kept for several decades, especially in the Japanese, rather than the Chinese, assembly. Cars of this brand meet all the requirements of multifunctionality and the highest practicality. "Ivushka" declared itself as the best domestic producer.

Cars Kakadu and Addi-Express have won their consumers with exceptional ease of use, so even children can entrust knitting.

In the market of mechanical machines, Knitmaster and Veritas Creative are considered absolute leaders.

Knitting machines were popular a few years ago. Neva-5 and Severyanka firmsbut today they are already out of production.

Firmly in demand products of firms Chernivchanka, Cascade, Bukovinka, Stoll, Singer, Toyota, as well as Inalsa and Donchanka.

In the segment of manual mechanisms, products of the following brands are distinguished.

Addi-Express Kingsize

This machine allows you to create a product with one canvas, as well as in a circle. For work, special skills are not required. All that is needed from the user is to fill the yarn and manually rotate the handle, the device will calculate one row after another.

Users note an increased speed of knitting products and agree that this is a very reliable design, the control of which can be entrusted even to children.

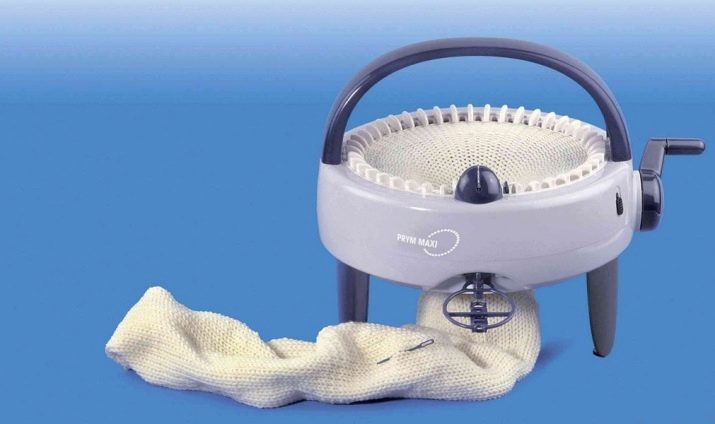

Ppym maxi

Hand knitting unit used for circular and straight knitting.

If you believe the user reviews, too thin yarn at the exit gives loose material, and too thick stalls the work, which greatly complicates the selection of suitable threads and limits the functionality of the knitting machine. Nonetheless, this design is quite simple, in the vast majority of cases it is used to make hats and scarves.

The following devices are among the best punching machines for knitting.

Silver Reed LK-150

This machine will be optimal for those who are just planning to master machine knitting for domestic use. It is optimal for knitting things of various degrees of complexity. The product is notable for its affordability, it gives a 95 cm canvas. A switch is provided in the design to select the appropriate required knitting density, so the needlewoman can set the desired parameters at her discretion. Due to the ergonomic carriage, you can simultaneously work with a pair of different threads.

Knitmaster SK360

The Japanese knitting machine is a fairly compact installation with a punch card control system. Reviews indicate that the installation is optimal for knitting all types of single-loop weaves. This unit is expensive, but, without a doubt, it justifies its value.

Veritas Creative

This knitting machine is a high productivity device combined with average cost. Using the device you can create knitwear of the highest quality and the most unusual weaves, including jacquard, as well as false openwork, clip, circular knitting and much more.

The best electronic cars.

Brother KH 930 / KR 850

Compared to many other electronic machines, this model involves a multiple increase in working life, while being easy to use. Those who have just started acquaintance with machine knitting, it is best to start with this model. The set includes an openwork carriage, so you can create weaves of very different difficulty levels.

Users note that such a machine allows you to knit several products per day, and in such an intensive mode, the design can work for many years. Most often, the machine is used by those who carry out things on order.

Silver Reed SK

Double-circuit machine, refers to units of the fifth class. The design allows you to create the most complex and intricate patterns, including those designed independently. Products come out in high quality and are in no way inferior to branded store models.

Essential Accessories

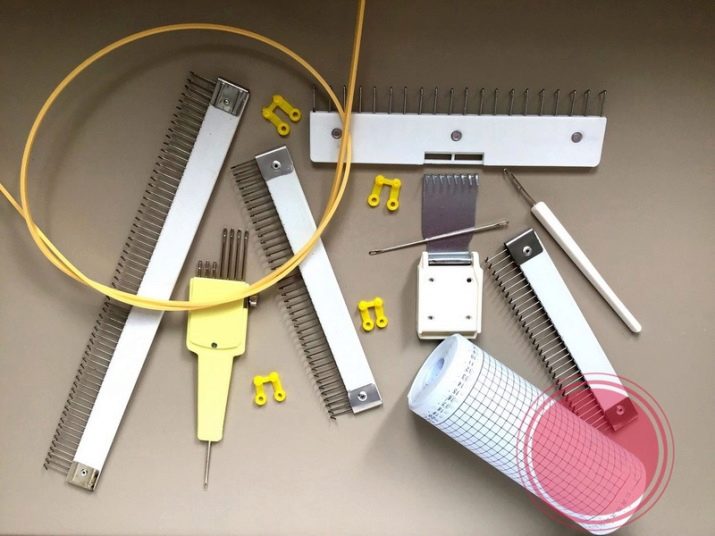

For knitting on a typewriter you will need the following accessories:

- selector comb with aligned edge;

- metal rulers for parsing needles in a needle bed;

- loop catcher - necessary for tying loops;

- hook;

- cord.

In addition to these tools, you will also need some additional accessories. So, always at hand craftswomen must have knitting needles - they are necessary for performing separate manipulations with loops. For example, they allow you to remove the canvas from the machine or return open loops to their place. Usually included with a typewriter crochet hookbut, if desired, you can purchase hooks of other sizes. They are used in the assembly process of finished products.

On the table of any craftswoman must be lying a small piece of paraffin - they are treated with threads if they are too hard to go. Needlewomen will certainly come in handy auxiliary threads when sweeping parts of a product or folding a slippery row. In any work related to the creation of the canvas, scissors will always come in handy - with them you will cut the threads and cut the neck. Surely useful in work set of decorative pins - they are clearly visible on the knitted fabric.

All accessories should preferably be stored in a chest of drawers out of the reach of children.

Which yarn is suitable?

Usually for hand knitting use yarn in skeins. However, for machine work it is better to use bobbin yarn - it is fed to the structure in a continuous mode and does not require frequent stops to bind the ends of the threads. In addition, the uneven movement of the yarn from the skein often becomes the cause of its breakage.

Traditionally, bobbin yarn goes in one thread. When working, it is desirable to combine several threads at once, for this they are fixed on the holders and the ends from each bobbin are directed to a special thread guide. To obtain thin products, usually two threads are folded; for thicker things, 3-5 threads are required to be folded.

We pay attention to the fact that for machine knitting, it is best to use yarn with minimal hairiness. In this case, it is possible to provide the easiest glide of the carriage without clogging it. If the hairiness is increased, you will have to constantly clean the carriage of accumulating pile, otherwise the equipment will very quickly fail.

It is not recommended for use in machines yarn that contains more than 20% of angora - the device will immediately separate it from the working material. Boucle yarn causes a lot of difficulties in the process, the same applies to yarn with bumps and other irregularities.

For machine knitting, it is undesirable to use threads on the surface of which lurex is located.

Selection tips

When choosing a knitting machine experts recommend paying attention to the following parameters.

- A variety. As we already mentioned, the machine can be single-circuit and double-circuit. The first device is distinguished by the presence of a single needle bed, where all the main rows are created, while the thickness of the finished fabric directly depends on the characteristics of the selected yarn. Products connected on such a machine usually have front and back sides, while creating complex ornaments, loose threads can remain on the wrong side, which spoil the overall impression of the product. In the two-contour design, as the name implies, there are a pair of needle beds, as well as additional prefixes - this design allows for volume knitting, the underside of such a fabric is usually smooth, dense and attractive.

- The method of applying the ornament. All devices are conditionally divided into mechanical, manual and electronic. For beginner craftswomen who are just planning to knit things, manual aggregates can be recommended. If your task is to regularly supply your loved ones with new products or engage in custom knitting, then it is better to give preference to electronic systems.

User's manual

If you decide to master machine knitting, get ready to face some difficulties. Everyone knows that knitting always begins with the formation of the first row. But the fact is that knitting machines “do not like” to follow this line - the carriage moves with great difficulty, the threads often break, the yarn does not bind, and often the unit simply does not work. A number of unsuccessful attempts cool the fervor, and the fuse for further work simply does not remain, which is why Before you master the work on a knitting machine, be sure to master the technique of forming the first row, after which you can quickly perform more complex operations.

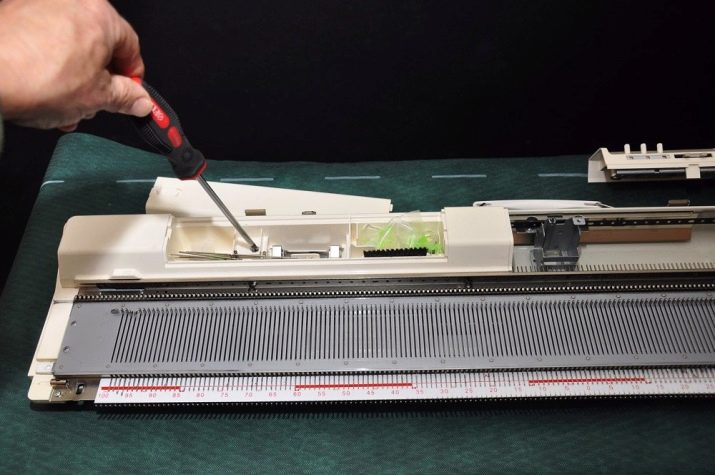

Any machine requires timely lubrication and cleaning. Outside the workflow, the machine must be closed. If you do not plan to work on it for more than a week, it is best to remove the bar with foam rubber, otherwise the spring mechanism will put pressure on the bar and the foam will fail very quickly.

Keep in mind - any needle is designed for 1460 hours of use, after which it must be replaced.

Every 2-3 years it is advisable to have your car inspected, for which it is best to contact a mechanic. The master will disassemble the structure, remove the old grease, apply a new one and replace the worn parts.

An overview of the knitting machine LK 150 see below.