Knitting machine "Severyanka" was at one time very popular and was in high demand among Soviet housewives. The demand for the machine was explained by the lack of knitted clothing stores on the shelves, as well as the desire of the craftswomen to dress their family in high-quality and beautiful things.

Characteristics

The production of knitting machines "Severyanka" was engaged in the production association "Mostrikotazhmash", which produces equipment for light industry enterprises. The collection consists of only two models - Severyanka-1 and Severyanka-2. Fundamental differences between them are not observed, with the exception of a more advanced carriage and an improved needle bar in a later sample. Both models do not have software and are manually controlled.

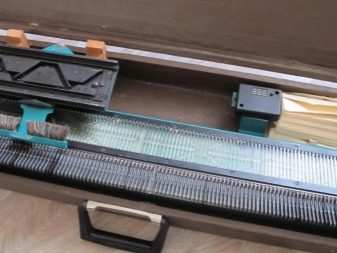

They belong to class 5, have a simplified carriage, a row counter and a knitting density regulator. The design is complemented by special brushes that are responsible for raising the tongues at the needles. Severyanka-1 is equipped with 203 needles, while Severyanka-2 has 210 of them.

The design of the machine includes needle beds, consisting of 168 rows, with steel grooves located inside, designed to move the needles. Needle boxes have 2 rails required to attach to the stand and slide the carriage. The coasters are made of sheet steel and equipped with rods with platinum springs.

Platinum, in turn, is represented by stamped parts with special grooves, which are a support for the needles when forming new loops. Along the platinum is a special shield equipped with discs with gaskets made of hard rubber. Discs are designed to fasten the threads before starting the knitting process.

"Severyanka" belongs to the class of 1-loop machines and is intended for knitting knitted fabrics with cooler stitching and knitting simple patterns. In terms of functionality and quality of knitting, the machine is significantly inferior to modern automated samples, but it is much cheaper and quite suitable for beginners. Cars were produced in sizes of 108x14x6 cm, which allows you to work on them in small-sized apartments.

Knitting on the "Severyanka" can be carried out with pure wool, half-woolen, cotton and synthetic yarn with a linear density of 200 to 350 tex.

Advantages and disadvantages

Despite his advanced age, “Severyanka” is still preserved in many families and is actively used for knitting things. The popularity of the model is due to a number of positive qualities that distinguish it from other machines of that time.

- The machine is very easy to use and does not require special skills.

- Thanks to the elongated design On the machine you can simultaneously knit several small things at once.

- "Northerner" is a universal device. She is able to knit not only large things, but also products such as mittens and socks.

- Low price favorably distinguishes the machine from expensive analogues and makes it accessible to a wide population.

- Despite the simplified design of the carriage, the machine is quite suitable for knitting multi-color canvases, decorated with a pattern or ornament.

Along with the obvious advantages, the Severyanka still has disadvantages. They include noise at work, low carriage functionality and the need for constant monitoring of the position of the reeds to avoid skipping loops.

In addition, the appearance of the unit hardly fits into the modern interior and looks quite old-fashioned.

User's manual

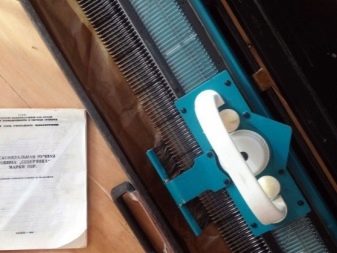

Each model of the Severyanka was equipped with instructions for use, but in the 40 years that have passed since the release of the first sample, most of them were irretrievably lost. In this regard, novice craftswomen often have difficulties with the development of knitting techniques, especially with the formation of the first row. Below is an algorithm of actions that will help to understand the principle of the machine and to link your first product.

- In order to tie the first row, using the comb, set the required number of needles, setting the knitting density regulator to the minimum value.

- The carriage is empty 2 timesthereby pushing the tongues of the needles.

- Slightly stretched thread is lowered onto the needles.then, holding the carriage with one hand, go from left to right.

- Previously unused needles translate into working position.

- Under the platinum hooklocated on the right side of the machine at the first needle, spend the thread.

- Working needles are moved to position B or D depending on the desired pattern, not forgetting that in position A the loops will not be knitted, since they are locked.

- The working loops advance and open. The thread is laid along the edge, after which the tongues are lowered.

- The carriage is drawn from right to left, returning it in this way to its original position. Then check the quality of the first linked row.

- The knitting density regulator is set to the desired position in accordance with the thickness of the yarn. Then they continue to work according to the same scheme.

- In order not to stray from the row count, use the built-in counter.

- If the loops need to be cut, then with the help of dekker extreme loops combine and knit together.

- If, on the contrary, you need to add new loops, then under the tongue of the needle thread the thread and hold the carriage. The lower edge of the new loop is weighted, otherwise the loop will not fail when forming the next row.

Separately, it should be said about the density of the knitting, on which the appearance and quality of the knitted fabric depend. The density regulator is a scale with a wheel and the numbers and risks plotted.When switching the regulator, the length of the loops changes, which affect the density of the knit.

For each type of thread, its own value is optimal. For example, when knitting with thin threads (400 m / 100 g), the regulator should be in the “0” position, while when working with very thick yarn (200 m / 100 g), it can be safely set to “10”. When knitting products of large thickness, the carriage moves slowly, and the loops are knotted with difficulty.

Common knitting problems are uneven loops, thread slipping off the needle, different row heights, and thread carriage tightening. Eliminate them will help adjust the density of knitting and the timely displacement of goods. To reduce the risk of slipping the loops, the load should be placed as close to the needles as possible.

An equally common problem is damage to the needle, or rather, its tongue. As a result, the loop worn on the faulty needle does not knit, resulting in a large number of threads accumulating on the needle. In order to fix the problem, you will need two screwdrivers and a new needle. Using one of the screwdrivers, unscrew the screws that fix the clamping bar located above the needles. In this case, unscrew both screws located from the needle on both sides.

A second screwdriver is inserted between the needle bar and the pressure bar so that a damaged needle can be removed. Then in its place put a spare and put the screws in place. Next, check the ease of sliding the carriage on the rail, and then pull the fasteners. It often happens that spare needles are long over, and a broken needle requires urgent replacement. In such cases, a whole needle is taken from the edge of the needle bar.

It should be borne in mind that using mohair and other fleecy yarn when knitting on the "Severyanka" is not recommended.

Otherwise, the machine begins to tighten the thread, skip loops and knit an uneven fabric. This is due to the fact that a long pile gets confused in the needles, interfering with the full operation of the machine. However, not all fluffy yarns disrupt the operation of the machine. Experienced craftswomen claim that from angora (rabbit fluff) and alpaca (llama wool), an excellent canvas is obtained.

Care Rules

Knitting machines "Severyanka" - the units are quite old, therefore, to extend their service life they need to be monitored.

- With regular use, the machine needs frequent lubrication, which is applied to the pressure bar and evenly distributed using the carriage.

- After a long period of inactivity, the machine needs to be cleaned. To do this, the grooves are well cleaned from fluff and dust, after which the unit is lubricated with household clarified oil.

- In no case should you lubricate the carriage with paraffin. An easy move over time will result in the failure of the part.

- If the machine is not planned to be used in the near future, it should be wiped with a clean dry cloth and put into the cover.

Next, watch a video with tips on how to type the first row on a single-loop knitting machine “Severyanka”.