The quality of bicycle wheels depends on the level of performance of their elements. The wheels consist of three items: bushings, rims and spokes. In this case, the spokes are a connecting element of all parts. From the material in this article you will find out what they are and how to choose the right option.

Why do you need it?

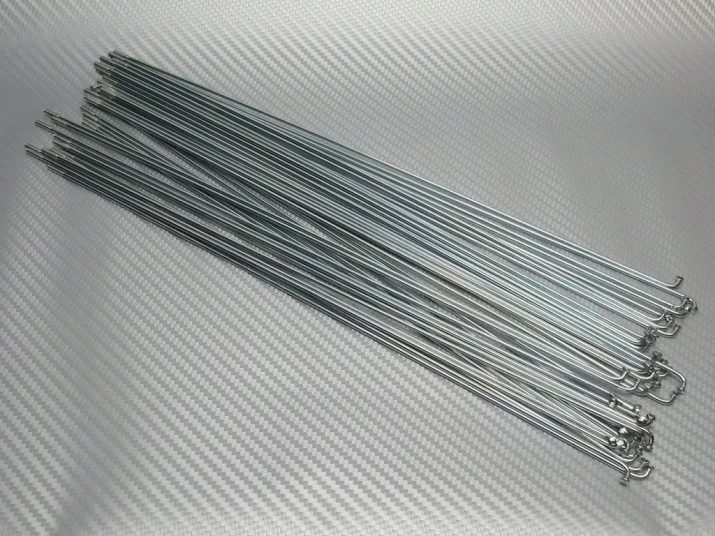

A bicycle wheel spoke connects the hub to the rim. Due to it, the wheel gains high strength with low weight. In addition to ensuring the integrity of the structure, the spokes are a kind of shock absorbers. Due to their flexibility, it is possible to distribute the load along the rim. Having a vertical position, they overcome the force of gravity.

They consist of a shaft and a nipple or mushroom nut, which is necessary for fastening to the rim. The riveted end of the rod is bent, on the second there is a thread (threaded or knurled). Options of the second type are considered more reliable and durable. Bicycle spokes center the rim, hold the shape of the wheel, in addition to strength, give it rigidity.

Classification

There are several ways to classify bicycle needles.

According to the material of manufacture

In the manufacturing process using different raw materials: stainless steel (chromium molybdenum), aluminum, carbon, titanium. Steel products are chrome plated or nickel plated. Aluminum needles are used when it is necessary to reduce the weight of the bike itself. Carbon and titanium products have a small weight, but a high price. They are used for sports models.

Nuts are made of bronze, aluminum and steel. The first ones are good because they stick extremely rarely, which simplifies the replacement of needles if necessary. Steel differ in budget cost, although specialists like them less than bronze products. Aluminum options are more expensive, but they make the wheel structure easier.

According to the method of production

All varieties can be conditionally divided into 3 lines: rolled, flat and drawn type. Variants of the first group are considered the most common, due to their simplicity and low cost. They are made of a steel bar of the required diameter.

Moreover, the thickness of the modifications is the same along the entire length.

Often these varieties are called cylindrical with constant thickness. They are characterized by a wide range of profiles and can have different lengths. The disadvantages of the products are their weight and the need for frequent replacement.

The second line consists of modifications of the cylindrical type with butting. They are relevant when riding a bicycle when the wheels get sudden bumps. These are pull-type options for off-road enthusiasts. Absorbing part of the pressure, they transfer the rest to the frame and steering wheel. Variable thickness contributes to better load distribution.

Due to cold forging technology they can be stretched without any damage to the molecular structure of the material used.

Such knitting needles come in one, two thickenings and triple butting. Priority options are considered the second type of model. Triple thickened products are needed for electric bikes as well as downhill.

Analogs of a flat type differ from rolled products in a flat shape. They are aligned on one plane, due to which aerodynamicity and final strength are increased. Their cost is higher than rolled products.

In professional circles they are called aero spokes.

They have an aerodynamic profile to reduce air resistance. These are varieties of the butting line, which differ in variable thickness. Often their profile is compatible with all types of bushings.

By size

The entire range of goods for sale is divided into 2 groups: direct and indirect types. Variable cross section options include several rulers.

- Single-butted. Rare, thickened at the end with a head. They are used if high strength is required on wheels with a rim having standard openings.

- Double-butted. Contribute to the weight loss of the bike, thickened at both ends, but flattened in the middle. Excellent stretch, transmit part of the voltage to adjacent spokes, effective in shock loads.

- Triple-butted. They differ in three different section diameters. A great option for those who need durable and durable bicycle spokes. They have the advantages of the first two types, suitable for tourism with cargo.

- Aerodynamic elliptical. They are distinguished by streamlined forms, in the middle they are like an ellipse.

- Aerodynamic flat. They look like a drop-shaped or flat profile. Wide for a standard sleeve, which means that when fastened, holes have to be made in the flange.

In size and caliber

Product size depends on the type of bike.

For instance:

- models for children and adolescents fit options with options in 12 and 16 inches;

- trial needs products in 19 and 20 inches;

- 20 ”spokes are suitable for BMXs, ligades and folding bikes;

- rear-wheel modifications for derth, street, downhill and freeride need 24-inch products;

- the main part of mountain bikes need products with a dimensional characteristic of 26 inches;

- 27 inches is considered a size for obsolete bicycle wheels;

- 29 inches buy for mountain, hybrid, as well as urban bike models.

The thickness of the spokes is usually measured in mm. Depending on the type of bicycle spokes, its performance can be 1.6, 1.8, 2, 2.3 mm. Moreover, depending on the bike, the models for the front and rear wheels may be different. The thickness of the reinforced models is 3 mm in diameter. Such options are used for motor wheels. Nipples are 12, 14, 16 mm long. The parameters of the spokes are selected according to the diameter of the entire wheel.

To find out the necessary parameters, one has to resort to deriving a special formula or using a length calculator. The second method is much simpler, you can find Russified applications that are able to adjust the geometric length of the spokes by 1 mm. The simplified formula is as follows:

SpokeLengthx = SQRT (Wx2 + Dx2 + ERD2-2 * Dx * ERD * cos (360 / (N / 2) * K).

Decoding:

- SpokeLengthx - right or left knitting needle (xR or xL);

- Wx - WR or WL (length from center to flange);

- Dx - DR or DL (flange diameter);

- S is the diameter of the hole for the spoke.

In the assortment of brands you can find products with a length of 175, 184, 186, 188, 252, 254, 262 mm. Based on the variety, the needles can be typical or colored. The latest options are made of stainless steel.

In count

In England, 72 spokes (32 front and 40 rear) were originally installed on adult bicycle wheels. In other countries, 36 spokes were put on wheels. For a typical bike, this amount was quite sufficient. Their number for the analogue of the highway type can be less (28, 24 pcs.).

It was believed that the reduction allows for greater maneuverability in terms of changing speeds. Marketers believed that for a good ride, it is enough to use no more than 32 pcs. on each wheel.

However, despite experiments with an extreme number of spokes (16 pcs.), The best strength characteristics are possessed by wheels in which 36 spokes are inserted. Products with less are suitable for amateur cyclists. Wherein the number of spokes in different models can vary, however, it should always be a multiple of 2 or 4.

By knitting

The spoke options may vary. This is due to the different type of load (it is significantly less on the front wheel).

The spoke of the front and rear wheels is radial and tangent (straight and cross-shaped). In the first case, the spokes go from the rim to the hub. This type of knitting is not considered the best, it is not so reliable. However, this option looks aesthetically pleasing and quite suitable for the front wheels of a bicycle. But when the buyer sets the needles using this method, he loses the guarantee.

In the cruciform mounting option, the spoke is attached to the sleeve not directly, but tangentially. In this case, it intersects three times with other spokes between the sleeve and the rim (option 3X). These wheels are stronger and more reliable. In addition to knitting in 3 crosses, there is 4X knitting.

Which to choose?

The best option will be the model of the same type that are in wheels. Today you can buy them individually, and therefore it will not be difficult to replace a broken spoke.

When there is a need to replace and select the right type of knitting needles, pay attention to several rules for a good purchase.

- Do not take expensive products if they are not needed. For example, non-professional rider fit options from stainless steel. A professional needs enhanced modifications.

- The type of bicycle spokes should depend on the expected loads. A beginner does not need reinforced modifications, which are also difficult to get.

- You need to take models with medium thickness, at an affordable price. The number is taken, starting from the needs and parameters of a particular rim.

- For length, consult a consultant. It will quickly help you determine the right option, based on the diameter of the rim, make of the manufacturer, dimensions of the sleeve, type of spoke.

- The geometry for a beginner should be simple or flat, with an optimal increase in loads on rough terrain.

- It is better to choose inverted knitting needles, due to which the moment of inertia decreases.

- The best position for the spokes is the pair-cross. In this case, it will be possible to increase the transverse rigidity and the tension force, evenly distributing the load on the rim.

- The ideal number of knitting needles is 36 pcs. The minimum number for the front wheel is 28 pcs. For a tandem, the best option is to buy 40 or 48 knitting needles.

- The type of thread is important. Knurled knitting needles are more durable but more expensive.

In the next video, you will learn how to properly pull bicycle spokes.