Today, cyclists who do not put a motor wheel on their bike are increasingly called retrograde. “Only the wind, only the pedals, only the extreme” - such an appeal is becoming less and less relevant. A pampered urban consumer, accustomed to driving a car, even if he buys a bicycle, will soon be inclined to put a motor wheel on it, all the more so such devices become cheaper year by year.

Features

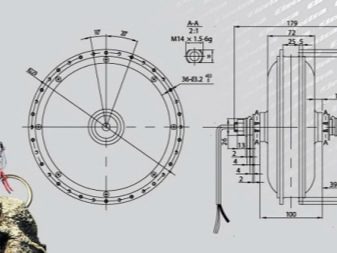

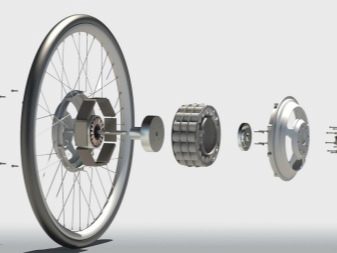

A bicycle motor-wheel functions according to the same principle of operation. It doesn’t matter whether it’s direct in it (directly from the rotor) or in gear (reducing the engine speed per gear ratio). Every electric motor for a bike includes a stator and a rotor. Magnets are attached to the rotor. Their field, interacting with the electromagnetic field of the stator coils, makes the rotor spin.

The stator itself is a coil wound in the gaps of the frame, consisting of steel plates. Most often, these plates are made of electrical or transformer steel. The design of the stator has the form of a polygonal frame with rays converging in the center.

Windings are coils wound from copper enamel wire. Copper is the best conductor. The number of coils is up to several tens, but this number is a multiple of 3. The motor wheel resembles a three-phase motor, in fact, this is the case: for stable rotation with a certain force, alternating pulses resembling a three-phase variable are fed to the coils spaced apart from each other in phase. voltage. In fact, this is not a sinusoidal form of an electric signal, but a sequence of rectangular pulses of constant voltage. They, in turn, are formed by the driver - the controller board, using the energy of the power source (battery).

The constancy and efficiency of rotation of the rotor is provided by three Hall sensors. Their work is organized as follows:

- fixing the position of the rotor relative to the stator;

- perception of the magnetic field from magnets;

- signal forwarding to the driver;

- pulse formation on the driver for stator coils.

To control the speed of the bike, or rather, the number of revolutions of the rotor per minute, a gas handle is used. The bicycle braking sensor stops supplying current to the engine.

Advantages and disadvantages

The advantages of using a motor wheel are as follows.

- Increased efficiency - not less than 90%. Not every electric motor has such a coefficient - for example, for collector motors, for which an inverted direct current is in no way sufficient, the efficiency is less than 70%.

- Ease of execution, reliability.

- There are no rubbing parts (for example, rings and brushes) - the engine can work for decades, if the manufacturer does not save on the quality of materials.

- Possibility of fast driving: a half-kilowatt motor-wheel gives a rotary force, during which the bike reaches a speed of up to 45 km / h on roads without a slope.

- The ability to remove the kit if necessary, giving the bike its original equipment. When reinstalling the motor kit, the appearance of the bike will not change significantly - the motor is installed only on the wheel itself.

- Significant relief of driving in the rise and against the wind.

- Uniform and smooth operation of the motor will provide quick adaptation to a new speed and gearless acceleration.

- Completely silent operation of a motor wheel.

The disadvantages of this installation is also not without.

- Low torque - less than motors of other types and varieties.

- Inability to create a more compact design based on such a motor.

- Increased weight. Some other motors, for example, the same collector one, have significantly less - 1.5 times or more - weight.

Nevertheless, in general, these motors are reliable and durable - they belong to brushless motors. This is why they attract bike-makers.

Species overview

All ready-made kits, which include motor wheels, are completed controller and battery. However, those who do not put the motor wheels complete with the rest of the parts order all the system components separately: the motor wheel itself, the battery and the controller with a throttle stick.

Before building an electric traction system, a beginner is faced with a gear and gearless motor wheels. The gearbox uses a gear transmission mechanism, where the rotational speed (number of revolutions) of the electric motor itself is several times — by the gear ratio of the gearbox — greater than that of the shaft, which eventually spins the wheel.

The gear wheel increases torque, but reduces the speed of the cyclist to 30 km / h. In a gearless drive - a wheel with direct drive - the gearbox itself and the associated losses are missing, which frees the mechanism from rubbing gears, which are much more often in need of lubrication than the engine bearings themselves. Torque is significantly lower at power up to 1500 W, but it becomes possible to accelerate to 50-100 km / h depending on the motor power.

A motor-wheel with the possibility of recovering (returning) a part of the consumed electricity allows you to return it in a small amount - about 6% of the spent power. Since the efficiency of such a system due to natural losses in the wires, windings, the controller and the battery cannot be equal to unity, it will not be possible to do without an external investment of additional energy. And there are only two ways to replenish the supply of electricity.

- Switch the motor-wheel to battery charge mode. Then pedaling will be at least twice as heavy - due to the braking exerted by the load on the windings.

- Find a place to simply charge your batteries. The best option would be in which solar panels are placed on the backpack and on clothes, when traveling on a motorized bicycle is completely autonomous.

In addition, at the beginning and at the end of the descent, the motor-wheel brake is not applied. And it, as already mentioned, in the generator mode significantly extinguishes the ride speed.

Also, the motor wheel can be rear - mounted on the rear wheel. Similarly put the front. Then the bike becomes rear- or front-wheel drive, respectively. To significantly increase the speed, you can make the bike all-wheel drive by motorizing both wheels.

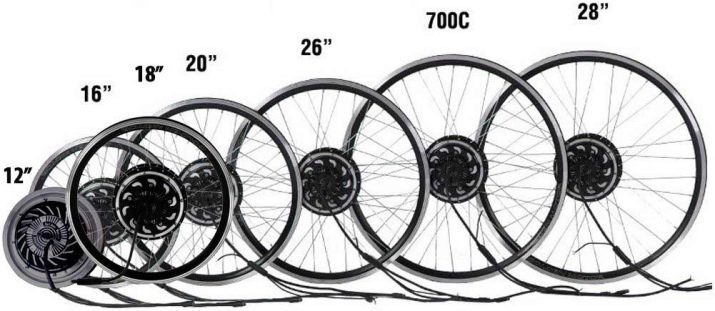

Dimensions

The size of the motor wheel is determined by the diameter of the rim. Whether you have a diameter of 29, 26, 20 or 16 inches, speed and traction depend on this. The larger the diameter of the rim, the greater the speed, but less traction, and vice versa. With less traction, you will accelerate longer. You can add traction in only one way - to help the motor with pedals.

A variant is possible in which you can re-pin the wheel from a regular hub to a motor one, using, for example, for a rim with a diameter of 28 inches, needles from a regular bicycle with 20 inch wheels. Those who do not know how or do not want to mess with a full exhaustion of spokes are advised to immediately order in China a ready-made motor wheel with the right engine type.

Selection tips

Decide what exactly you want from your bike.

- Speed up to 35 km / h without much effort and any special level of physical development. At the same time, your bike does not get rid of its original functions - at any time you will switch back to pedaling with your feet at will. Such a modification is worth a total of $ 350.

- 50 km / h – complete set of an electricopedist. At the same time, you can not switch to pedaling just as easily - the battery pack, a more powerful motor wheel and the same controller weigh 5–10 more kilograms more. The price of refinement is from $ 600.

- The bicycle will become an electric bike - an electric motorcycle. You can easily accelerate to 90 km / h. But remember: in this case you will definitely need reinforced rims and bushings - maybe, like on a bicycle tandem. The fact is that enhanced traction requires increased load. Your thin rims from a road bike will simply fall apart, and you can break. The price of finalizing a bike for an electric motorcycle will cost at least $ 2300.

Whatever you prefer, you yourself are responsible for your choice.

Minimum electric bike

The mass of the set for an electric bike - a motor on a wheel (without a wheel spacing), a battery pack and a controller - will be at least 4 kg by weight. This is enough for a normal ride around the city or on country roads. Good engines are produced, for example, by a company Bafang 8fun. The working power of the engines is 250–750 W, but if the power exceeds 350 W, such a motor can noticeably overheat, which will significantly reduce its service life.

The weight of the motor wheel (without rubber) is at least 2 kg. To develop a speed of up to 35 km / h with an average rider weight of 90 kg, he is quite capable of it - the rider himself may not make any effort to pedal. The same can be obtained without a motor, by switching to the last speed from the pedals and when driving without lifting or lowering. When riding uphill, the help of a cyclist through pedals will be required - the engine may not overpower the climb. In combination of both, you can get the speed produced by a one-kilowatt engine, switched on at the start. Mobility and relative lightness of the bike are guaranteed.

The same set can be chosen for children, and more precisely, for a teenage bike. But greater than 250 watts, the power of the motor wheel for him will be unattainable. "Teenage" frame is not designed for more than 65–70 kg, weight.Traffic regulations prohibit children under 14 from using any electronic bicycle kit.

There is no need for a half-watt motor wheel — it weighs not 2, but 4–5 kg in itself, while taking twice as much electricity from the battery of batteries as its 350-watt counterpart. A 500 ... 600-watt motor-wheel is a “crutch” that has not passed “natural selection” either in projects or in practice among users: some cyclists noted that the sense in the end from it is less than from a 300-watt.

In the “moped” assembly

This configuration allows not only to obtain a speed equal to an average of 48 km / h, but also to easily conquer any climbs in the conditions of the city and mountain routes. To achieve such results, it is necessary to select an engine with a capacity of 1200-1500 watts. Such a motor wheel has a mass of 6-8 kg (excluding rubber). Providing an uninterrupted power supply to such a motor will help more heavy and expensive battery pack weighing at least 5 kg.

At the risk of increasing the voltage from 48 to 72 volts, you will get the speed limit for the city - at least 60 km / h, but at the same time, the motor will overheat faster and stronger, which forces it to be launched only for a short time.

Motorcycle Set

Altering a bicycle for motor traction, say, by 3 kW, will force the owner to strengthen the frame. Firstly, both the kit and the thrust created by an engine of the order of several kilowatts will require increased load. Otherwise, the wheels will be the first to suffer (huge “eights” appear on the rims), then the frame itself will begin to fall apart - the body kit of the batteries and the controller will add at least 15 kg. The maximum permissible load is only twice as much as the rated load, this is the basic rule for all motor wheels.

To put a reinforced set for a category III electric bike, you need to strengthen the dropouts, completely change or retrofit the frame feathers, put a special balancer, like on real motorcycles. A rated engine of 3 kW already has enough power to deform the feathers of the frame for a regular bicycle, even when you drive it in stationary mode, lifting the wheel on which the motor is mounted on a special suspension.

Without reinforcing the frame in a special way, you are unlikely to be able to use a motor with a power of up to several kilowatts. A speed of more than 40 km / h requires already good depreciation - without it, you will simply be thrown out of the saddle, if you run into a small bump or a crack across the road. The plug is from a motorcycle or from a downhill bicycle (the latter has an impressive mass and the highest strength, unattainable for bicycles of other types and varieties). The battery pack here also weighs from 20 kg.

How to install?

For lovers of a ride closer to extreme skiing, experienced masters advise to put the motor-wheel back. The rear motor-wheel is better off-road than the front - this is important in sharp bends that are driven at high speeds.

However, a slippery road is less manageable due to worse weight distribution. The situation worsens and the battery mounted on the trunk. Corrects the situation gear motor-wheel, which has a lower weight, lithium-ion batteries, which have increased specific energy. An alternative is lead-acid batteries on the middle (inner) tube of the frame. Still, the rear wheel-motor contributes to increasing the strength of the entire structure.

The motor must be consistent with the recommended rim diameter (wheelbase) and hub width. You can specify the diameter of the rim on the sidewall of the tire. The width of the sleeve does not go beyond 14.5 cm - most motor kits are designed for this value.

If it is impossible to combine the motor-wheel with a high-speed cassette (for example, 9 stars), change the latter to a 5-star one. As a last resort leave only one star or spread the feathers of the frame 2 cm. The last aluminum frame may not stand up - experiment on a steel frame.

The wire should not go out on the right, where the gearshift mechanism works, but on the left. Unscrew the nuts holding the motor wheel and take it out. Assemble the motor wheel according to the assembly instructions. If something is not clear to you to the end, contact the support team on the website of the company or store that sold you the motor wheel. Often, it is better to enlist the support of specialists, because you can easily burn the controller. And without a controller you won’t go unless you have a commutator motor that needs nothing but direct current.

Do not rush to tighten all the elements tightly until you are convinced of the operability and serviceability of the motor.

After assembly, try the motor-wheel idle - it should not “eight”. If this is not the case, remove the “eights” on the rim by pulling the knitting needles with a spoke key. Try the operation of the controller and throttle stick. If everything works properly - make a test run at low speed.

Installing a front wheel motor is easier. The front wheel itself does not contain any sprockets. There is simply nothing to interfere with the operation of the front motor-wheel. It doesn’t matter if you move the power cable to the right or left - in the direction of travel. Even if you open the fork, it will not affect the strength and stability of the bike.

The only thing - do not confuse the direction of the wheel: if installed incorrectly, without testing the engine, you will suddenly go backwards and the bike will turn into a vehicle with a rear steering wheel. The situation is paradoxical when the throttle stick is stuck: you can crash into a pole or collide with a car driving behind, even if it slows down in front of you.

The assembled motor wheel is afraid of showers, wading through rivers and swamps - when immersed in water or flooded with water jets, Hall sensors can fail. Take care in advance of sealing - or at least covering yourself from the direct jets of water - of the inside of the motor-wheel. Often, manufacturers themselves install special round flaps to protect the wheel from direct splashes of water and / or dirt while riding - make sure they fit the wheel spokes.

See how to choose a motor wheel for a bicycle in the next video.