The bathroom is one of the most important rooms in each apartment. The emotional state of a person depends on its aesthetic design and the quality of plumbing. In order to relieve stress after a working day, it is not necessary to visit expensive salons, you can just take a relaxing bath with your favorite aromatic oils. Modern manufacturers offer a wide range of bathtubs, which differ in size, material of manufacture and price range.

Recently, bathtubs made of inexpensive materials such as acrylic, steel and cast iron have been in great demand, but wood products are used only in the design of elite premium rooms. Nonetheless experts recommend paying attention to wooden bathtubs, which have unique properties and characteristics.

Description

Wooden bathtub - plumbing, which has high environmental performance and spectacular appearance. Wooden bathtubs have been popular for many hundreds of years.

Modern equipment and innovative technologies have allowed manufacturers to significantly reduce the cost of this product through the use of cheaper materials, the most popular of which are acrylic, steel, cast iron and plastic. New products replaced wooden goods from everyday life, but could not replace the emotional pleasure of contact with natural wood.

In modern everyday life, wooden bathtubs are practically not used, but they remain in demand in the implementation of expensive design projects.Depending on the model and shape, design, wooden bathtubs differ in size, weight, wall thickness and type of wood. The standard bath length is 180 cm, width is 80 cm, but these parameters can be changed depending on the model and type of construction. The mass of the product is in the range from 60 to 300 kg. If the design weighs less than 60 kg, then the purchase of this product must be abandoned.

Advantages:

- environmental Safety;

- the presence of a pleasant texture;

- high esthetic indicators;

- long period of operation;

- the presence of healing properties;

- pleasant aroma.

Disadvantages:

- high price range;

- drying out of the structure;

- difficulty in leaving;

- the need for regular application of a protective layer.

The quality and durability of wooden products directly depends on the type of wood that was used in the manufacture. Professional craftsmen recommend paying attention to the fact that not all wood can be used in the manufacture of bathtubs. The list of the most common tree species:

- larch;

- wenge;

- cedar;

- mahogany;

- oak.

Kinds

In specialized plumbing stores you can see a wide range of products for carrying out water procedures. The most popular types of bathtubs.

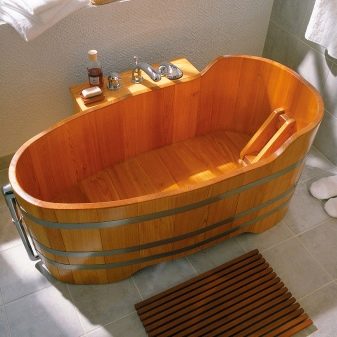

- Barrels - classic products that not only look like barrels, but are also made on the same principle. The shape of these products can be oval, round, and also in the form of a trough. The size and shape of the product depends entirely on the style of the room and the personal wishes of the owners.

- Rectangular - products that look like a box. Most of these products have a standard form. Advantages - ease of manufacture, reliability.

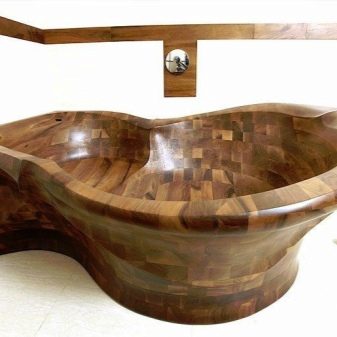

- Hollowed out - goods that are made from solid wood, and not from individual wooden elements. Advantages - the ability to reproduce any geometric shape, the presence of the maximum level of tightness, high aesthetic indicators. The disadvantage is the high price range, the difficulty of finding raw materials and manufacturing the product.

- Ships - the most popular products that have not only the shape of a ship, but also technological similarities with it. The advantage is a beautiful appearance. The disadvantage is the high price.

- Ofuro - Japanese font, which has the common features of a barrel and a rectangular box. Particular attention should be paid to the dimensions of the product: length - 140 cm, width - 100 cm, depth - 80 cm. Inside the bowl is a special protrusion that allows you to take the most comfortable body position during water procedures.

Manufacturing technology

A wooden bath is not only a plumbing item, but also a whole work of art, the manufacture of which requires knowledge, special equipment and high-quality raw materials. To produce a wooden structure, you must have the following set of tools:

- milling machine;

- roulette;

- marker;

- electric jigsaw;

- a set of tools for grinding;

- drill and set of drills;

- a hammer;

- adhesives and sealants;

- set of special brushes.

In order to make a bath consisting of several wooden elements, the following technology must be observed:

- drawing up design drawings;

- selection of raw materials;

- sawing wood according to the dimensions indicated in the drawings;

- mechanical removal of all irregularities and burrs;

- grinding all structural parts using a special machine;

- processing of parts with a primer and special protective equipment;

- assembly of the structure.

Connecting parts is a responsible and complex process that consists of several stages. The assembly of the bath begins with the interconnection of all the bottom parts with the help of wooden choppers, which are installed in pre-prepared holes impregnated with glue. All joints must be pre-treated with sealants.To give maximum reliability to the structure, it is necessary to nail the bars perpendicularly to the assembled bottom, the distance between which should not be less than 10 cm. The final stage of the bottom production is drilling a hole for water drainage and fixing special legs.

A prerequisite is the correspondence of the height of the legs and the size of the siphon.

This technology of work execution is the basis for the collection of bumpers. The only difference is the manufacture of connecting ends at an angle of 45 degrees. This indicator allows you to reliably connect all the parts and give the product absolute tightness. Specialists draw attention to the need to make holes on one side for a siphon. After completion of the work on the manufacture of the bottom and sides, it is necessary to proceed to the final assembly of the entire structure.

All seams of the product must be re-treated with hermetic compounds, and the excess removed with a soft sponge or cloth. After the product has completely dried, it is necessary to polish the inner and outer surfaces of the bath once more.

The final stage is the coating of the outer surface of the structure with special acrylic varnishes. This procedure must be repeated several times. Repeated application of varnish is permissible only after the complete drying of the previous layer.

Selection rules

In order for the product to maintain a beautiful appearance and structural integrity throughout the entire period of operation, experts recommend paying special attention to its choice. The main factor that you need to pay attention to is the material of manufacture and design features. Wooden bathtubs may consist of the following elements:

- solid tree trunk;

- large fragments;

- bars;

- planks;

- veneer.

Veneer constructions have the lowest price, and goods made from a single barrel have the maximum price range.

To reduce the cost of a wooden bath, some manufacturers Do not use natural wood, but only reproduce its structure. To detect fakes, be sure to browse the entire product catalog. In the event that the same model is made of different wood, but has the same price, you are dealing with an imitation of a wooden bathtub, the decision on the purchase of which each buyer must make independently.

Properties and parameters of low-quality goods:

- uniform pattern, which is repeated on the entire surface of the product;

- light weight;

- low price range;

- wide color range.

Significantly increase the cost of construction can use additional elements from another material. Some manufacturers combine wood with various metals, polymers and glass. To give the design a maximum level of reliability, some models are sold together with massive metal frames, which will also increase the total cost of goods.

No matter how much one wants to save money on acquiring a wooden bathtub, each buyer should understand that a quality product cannot have a low price.

Care Features

For the longest possible preservation of the integrity of the product and its high aesthetic indicators, experts recommend that you carefully approach not only the choice of a bathtub made of wood, but also strictly observe the rules of operation and maintenance. The basic principles of caring for a wooden bath:

- product cleaning is allowed only with special wood products;

- complete removal of moisture after water procedures, followed by wiping the surface with a soft dry cloth.

It is strictly forbidden to clean the wood with hard metal brushes and to use abrasive cleaning compounds. To prevent mechanical damage, experts do not recommend bathing pets in a wooden container, which with sharp claws can ruin the surface of the bath.If the operation of the wooden structure is not planned for a long time, then experts recommend pouring a small amount of water into the bathroom, which will protect the product from drying out.

A wooden bath is not just a bathing capacity, but a real miraculous font that can improve both physical and emotional state. A high level of employment and constant presence in a stressful environment has a negative impact on the health of a modern person. Therefore, experts when choosing plumbing recommend paying attention to wooden bathtubs, despite their high price range and the complexity of care.

Compliance with simple operating rules will allow for a long period of time to operate a wooden font without any problems and technical difficulties.

See the following video for an illustrative process for manufacturing a wooden bathtub.