With the development of new technologies, many new types of fabric have appeared on the light industry market. For their production very unusual raw materials are very often used. But despite the huge selection, many people prefer natural materials in the form of calico. This fabric appeared in our country as far back as the 15th century, when it was imported from Asia.

What it is?

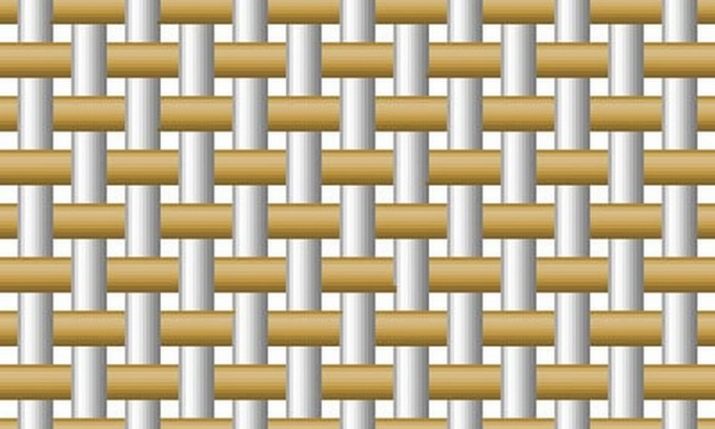

Coarse calico is a cotton material. The word itself came from the Arabic name for dense fabric, which was obtained using the cross method of weaving. Since the 16th century, we began to actively manufacture fabric in Russia and sell it at all kinds of fairs. Due to its low cost and high quality, the material was in incredible demand. Initially, it was used as a lining fabric for caftans. Over the years, they began to make it much softer, and it became suitable for sewing clothes. When creating the material, the simplest weave is used - plain.

Material Description:

- the fabric looks smooth on both sides;

- natural cotton is used for the manufacture, but sometimes synthetic fibers may be included in the composition;

- the fabric has a matte surface without any luster;

- it has environmental safety, does not cause allergies and has high wear resistance;

- in appearance, the fabric resembles a canvas, which is associated with special weaving crosswise;

- the surface of the canvas is always rough, if you hold it by hand.

The material is widely used for sewing sleeping sets. From it sew things for children.Coarse calico is often used in the manufacture of shirts and diapers.

Characteristics

Based on GOST, calico density is required to be approximately 145 g / sq. m

When buying material in a roll, you should distinguish between characteristics and density.

- Thin (sparse) fabric has a density of not more than 100 g / sq. m

- The material with a density of 110-125 g / sq. Is very popular. m. From this material and is the tailoring of the main part of bed linen.

- In accordance with GOST, the fabric should have a density of 140-145 g / sq. m

- Very rarely, bleached or printed calico with a density of 146 g / sq. m. This is the most dense and durable type of material.

An essential characteristic when choosing calico is the width of the material in the roll. The total amount of fabric that is required for sewing a particular product depends on the width. The greater the width of the roll, the less meters of fabric you will need to buy.

The width of the fabric may vary depending on the species.

- Bleached calico is sold in rolls 80 cm wide.

- Coarse calico goes on sale in rolls of 90 cm.

- A very popular parameter is a roll width of 1.5 m. Such material is often bought for independent sewing of bed linen. Most often, printed and one-colored fabric has this size.

- On sale you can find severe coarse calico 166 cm wide.

- Rolls with calico over two meters are very popular. Often they buy it for sewing a kit on a double bed. In such footage, printed, bleached or one-colored calico is sold.

Structure

According to domestic standards, the fabric should be made of 100% natural cotton. In China or Pakistan, the use of polyester yarn is permitted. But it should not be more than 15%. Due to its natural composition, it does not cause an allergic reaction and is completely safe.

A material mixed with synthetic fibers has a more pleasant texture, does not accumulate static electricity, is easy to care for, and absorbs moisture well, but can cause an allergic reaction in some categories of citizens.

Advantages and disadvantages

The fabric is very popular and is currently due to the large number of its advantages:

- very convenient to use;

- possesses high hygienic properties;

- has high strength and wear resistance;

- environmentally friendly material due to natural threads in the composition;

- differs in antistatic properties;

- possesses hypoallergenic characteristics;

- it is perfectly erased in many modes and very unpretentious;

- clothes and other products from this fabric are not deformed;

- The fabric has an affordable cost.

In addition to the undeniable advantages, the material has a number of disadvantages:

- the surface of the fabric does not have a beautiful glossy sheen, and it is rough to the touch;

- very budget options for fabric quickly lose their brightness;

- the fabric is rather dense and tough, which makes it unsuitable for sewing some things;

- during prolonged use, spools may appear on the surface of the fabric;

- the fabric is natural, so it can wrinkle a lot.

Species and their properties

The modern market of light industry provides consumers with 4 main types of calico.

- Coarse calico It has a pleasant creamy tint. This is unbleached fabric. According to its technical characteristics and density, this is the most durable type of fabric. It is often used as an upholstery for upholstered furniture. It is suitable for the manufacture of workwear. To sew such clothes, the fabric is pre-dyed.

- White calico not as rude as the first option. It has a lower density, being an excellent option for tailoring sleeping sets, shoe covers and other special clothes. Among a large number of varieties of calico, bleached has the highest cost.

- Plain dyed fabric has a similar structure, as in the second option.This fabric is plain and is used for the manufacture of budget linen for the bedroom. It is widely used as a lining fabric for tailoring suits and coats.

- Printed fabric happens with colorful patterns and is incredibly popular in the textile market. The linen for a bedroom from such fabric, and also pajamas and children's suits for the summer is very popular. The stores offer a wide range of calico in various patterns and colors.

Each fabric manufacturer is very interested in promoting their product in the consumer market. In order to increase the demand and marketing of fabrics, the assortment of goods is constantly increasing, new shades and patterns are created. Each consumer decides to buy domestic material from natural fabrics or imported with an admixture of synthetic fibers.

Comparison with other materials

Consider the differences between calico from other cotton materials.

- Chintz and calico have a similar weaving. However, much finer fibers are used in the production of chintz. Chintz has a completely natural composition. Various manufacturers can add synthetic fibers to calico. Chintz is sold in rolls with a width of 80 or 90 cm. This means that there will be a seam on bedding that buyers of finished products do not always like. Coarse calico is a little more expensive than chintz. And also natural chintz has an unstable color, which dims very quickly during operation. Currently, many manufacturers make chintz thinned out.

- The difference from satin in calico is significant. Satin got its name from the method of twisting fibers. They are very thin and fairly tightly twisted, which allows you to create intricate weaving. It also creates a sparkling surface near the fabric, unlike calico, which has a matte finish. Satin is very reminiscent of silk materials. It can go on sale in natural, artificial or mixed formulations. At a cost it is much more expensive. Experts do not recommend an affirmative verdict which of these fabrics is stronger.

- Poplin is a material that is made from fibers of various densities. Horizontal fibers are much thicker than transverse. If you look closely at the matter, then on its surface, you can find small scars. Initially, the poplin was silk, and the calico consisted of natural fibers. Domestic manufacturers make poplin based on cotton fabrics, and foreign materials can be imported with an admixture of natural fibers and synthetics in various proportions. The composition of the poplin may include woolen and viscose threads. It looks great in different colors and tones. The outer side of it shimmers a little. Poplin is much more effective in appearance, and it costs much more than calico. Coarse calico is much denser than poplin. Both materials have high wear-resistant qualities, but coarse calico will last much longer.

Poplin shrinks due to improper handling. This is especially true for poplin with the addition of silk and wool threads. Coarse calico is used for sewing sets of linen. Poplin was supposed to make various things. Poplin sleeping sets are becoming very popular, but they are much more expensive.

- Polycotton is a blended fabric that consists of polyester and cotton. From this fabric, bedding, blankets and mattresses are sewn. If it contains a greater number of artificial threads, then such a material is not suitable for sewing sleeping accessories, but their price will be much lower.

- The structure of the threads of percale and coarse calico are similar. Materials are very similar in their technical characteristics. Percale is much thinner and softer with tactile contact. Percale has a high density due to quality threads. Thin fibers are not twisted, but connected with a special glue.Percale bedding is premium and much more expensive than calico.

- Calico is different from cotton that shrinks during the washing process or is slightly deformed by improper care. The quality of cotton is much better than calico. During prolonged use, spools do not form on its surface. Nevertheless, the differences in materials are insignificant, and they are very similar to each other. This is a great home textile.

- Polysatin represents a certain hybrid from sateen and polyester fibers. The material has high strength, like calico. But unlike calico, it has a shiny surface. Yet the material is more relevant to synthetic fabrics. Due to its composition, the material retains an aesthetic appearance for a long time even with repeated washing. Such a material is much cheaper than calico due to the large number of synthetic fibers in its composition.

Application

Coarse calico is a fairly common material for creating things and accessories for the home.

- Most often, bedding is sewn from it. Such underwear has high performance properties. It is pleasant to sleep on it at any time of the year. Kits are very strong and durable. A wide range of patterns and colors allows you to choose the right option.

- From coarse calico make special clothes and uniforms. For sewing clothes, bleached or one-colored fabrics are used. It is great for sewing medical gowns, gloves, shoe covers and sheets in medical facilities.

- Calico material is indispensable if you need to sew home furnishings in the form of curtains, tablecloths, napkins or bedspreads.

- This type of fabric is widely used in the form of lining materials. Such popularity is due to the natural characteristics and high wear resistance of the fabric. It is well erased and has high wear resistance, which is ideal for linings.

Care Rules

The material is very picky to maintain and easy to handle. In order for the products from coarse calico to serve as long as possible, it is worth observing the basic rules for caring for such things.

- After buying things should be washed immediately. This will allow you to get a soft and pleasant to the touch material.

- Before sending to the washing machine, it is better to turn the fabric inside out. This is especially recommended for items with a pattern.

- It is recommended to boil and bleach calico. But it is better not to expose other types of fabric to such strong influence. Experts recommend washing other types of material at low temperatures.

- To keep the item in its original form longer, it is better to wash the calico separately from other materials.

- In order for the calico to retain all its qualities, to remain soft and easily ironed, it must be squeezed in the machine at medium or minimum speed.

- In order to quickly restore the shape of the product, it is recommended to shake the item after washing.

- Drying products made of this material is recommended in the fresh air or in a well-ventilated area. The fabric absorbs odors very easily and quickly.

- It is recommended to iron products from coarse calico when they have not yet completely dried. Due to moisture, the material will quickly smooth out and will be soft.

It is important to remember that calico sits after washing. So that shrinkage does not occur on the just sewn thing, it is worth washing the fabric in advance, and only after this proceed with sewing the intended product.

About what material to choose bedding from, see the next video.