Since the first skateboard appeared in 1958, its demand has been constantly growing. He gained the most popularity among young people seeking to diversify their lives with extreme hobbies.

After purchasing a board in a store, over time, many owners begin to notice that the skate is not moving as fast as immediately after the purchase, extraneous sounds appeared. There may be several reasons. One of them may be the wear of bearings that are in the wheels. This is due to the fact that during riding dust, dirt and sand get into them. As a result, the wheels begin to spin worse, the skate moves jerkily or stops at the most inopportune moment. In this case change bearings or clean them.

Bearing replacement

To work, you do not need a tool kit, just a special key for repairing the board and a new bearing or kit. If there is no such tool, you can use a wrench (size 13) or an adjustable wrench. The operation to replace the defective part will take no more than ten minutes.

The whole process of restoring a skate can be divided into several stages.

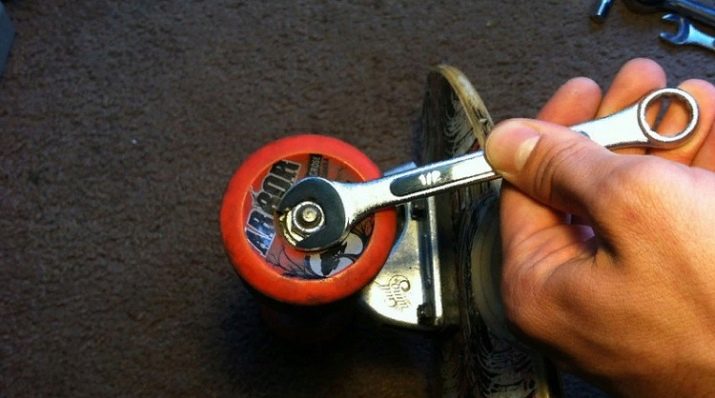

- Unscrew the nut on the wheel with a special key. This must be done counterclockwise.

- Remove the spacer (represents the washer) between the nut and the bearing itself. Do not throw the spacer, it will be needed later in the assembly.

- Remove wheel with failed bearings. There should be a washer at the bottom, it can be left in place. The washer must not fall out of the socket.

- Remove defective bearing.To do this, it is necessary to insert the wheel on the axle so that its end touches the defective part quite a bit, but does not reach the wheel. Then, very carefully, slowly tilting the wheel to the axis of the skate at an angle. The bearing will slip out. All operations should be performed slowly and carefully so as not to damage anything. This warning is relevant if the defective element is planned to be used in the future. If not, then you can not be careful. There is a hub in the wheel.

In this case, when replacing new bearings, it is imperative to reinsert it.

- Repeat previous steps with other wheels. Then insert new or thoroughly cleaned from dirt and dust old bearings. In the presence of coloring it is recommended to install them with the painted side out.

- Now you need to insert the bearing into place by gently pressing on the outer metal ring. You cannot press the center of the bearing itself. The pressure should be where the border with the wheel passes. Carry out a similar operation with the rest of the wheels.

- Replace gaskets.

- Tighten all nuts on the wheels clockwise. Please note that in the process the axis of the board must not go beyond the nut. So you can avoid thread breakage on the axis. In addition, you should not tighten the nuts very much, as the wheels will turn with difficulty.

- Check wheels for torsion. Small clicks should be audible, like crackling, but loud noise is already abnormal.

If the wheels rotate without jerking, with enough inertia to move, you can continue to ride.

Bearing cleaning

Regular cleaning of these parts allows you to reduce skate wear, significantly increases its speed and helps prevent wheel jams. If bearings are not cleaned in a timely manner, the likelihood of accidents when using the board increases significantly. The cleaning operation itself is simple, it can be done independently at home, without involving a specialist and money spent on his call and pay for the work.

To start cleaning, remove the bearing. The whole process is described in detail above. In order to avoid the loss of important parts (bolts, washers, spacers) it is better to keep them all together, for example, in a box or plastic bag.

Cleaning is recommended in the following order.

- Clean the main sections of the bearing from dust and dirt. To remove obvious areas of contamination, wipe it with a napkin or dry cloth. To clean the most problematic areas, you can use a solvent.

- Prepare a solution for cleaning. To do this, you need a clean container and a cleaning agent (acetone, grease cleaner, white spirit or rubbing alcohol). Rubber gloves are recommended for protecting hands.

- Place bearings in a container filled with cleaning agent.

- Rinse the items and wait a while until the parts are completely clean (about 10 minutes). If the cleaner has darkened, it is recommended to carefully drain it and pour new cleaning agent into the container. The operation should be repeated until the elements are completely cleaned.

- Remove the sleeve, remove the rubber insert from the bearing itself. To do this, pry it with something thin, for example, a paper clip or a sewing needle. If it fails, you can insert a needle between the outer ring of the bearing and the sleeve. After that, carefully lift the rubber grommet until it comes out of its seat.

To do this, they can be laid out on a clean rag.

How to lubricate a bearing?

Before lubricating parts, it is recommended to dry them. It takes no more than 15 minutes. To speed up the process, you can use a can of compressed air. To do this, direct the jet to the open side of the element.

Then, apply special grease to the bearing. Enough 2-3 drops for one part. For uniform lubrication, the bearing should be turned over.

The use of vegetable or motor oil can lead to clogging of parts. Using the WD-40 is also not recommended. It can act as a cleaner in some cases, but not a lubricant, in addition, it reduces the life of parts.

Next, you need to put bushings in their place. At the same time, check that there are no gaps between them and the bearing. Then you can insert the bearings.

If the skate is equipped with a separator (synchronizer), you must install the part back. To do this, the wheels are attached to the chassis, but the nuts are not tightened very tight. The wheels should swing slightly. If the wheel rotates poorly and stops, it is necessary to loosen the nut holding it.

Specialists strongly recommend the use of greases suitable for all models. To achieve ease of rotation of the wheels, you need to “roll” the board for about a week. But at the same time, it is enough to lubricate the bearings once a year.

Lubricate at a rate of about 40 percent of the free space inside the bearing.

Never use water when performing operations when lubricating bearings.

Maintenance of non-separable bearings

To do this, remove one boot. At the same time, he will bend and become worthless. Do not be upset, because in the future he will not be needed. After flushing and lubricating, the bearing is installed in the wheel with the open side.

The absence of one boot will not significantly affect the performance of the skate, since the bearing fits snugly against the walls of the wheel. That is why you should not be afraid of dust and dirt. The cleaning process of non-separable bearings is similar to the steps indicated above.

Subject to all the conditions for the care and replacement of problem parts described in this article, you can count on a significant increase in the operating time of your skateboard.

You can find out how to properly clean bearings on a skateboard by watching the video below.