Sewing machines seem to be a very simple and even primitive product. However, many are poorly aware of their working principle and basic types, as well as how such things appeared. Meanwhile, only knowledgeable people can do the right choice and use of a sewing machine.

History and antique models

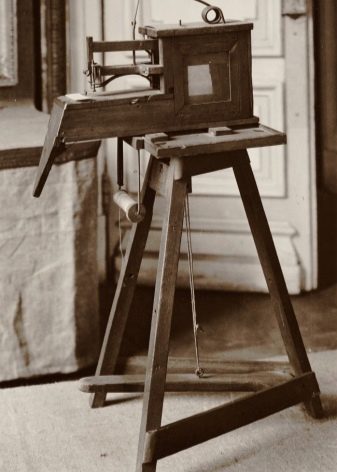

It is generally accepted that sewing machines were invented in the second half of the 18th century. Initially, they tried to simplify sewing directly, reproducing manual work as accurately as possible. The effectiveness of this method turned out to be extremely small.

And almost no one but the inventors themselves needed such devices. Everything changed in 1814 when a tailor from Austria named Joseph Madersperger invented a needle that has an eye at the sharp end.

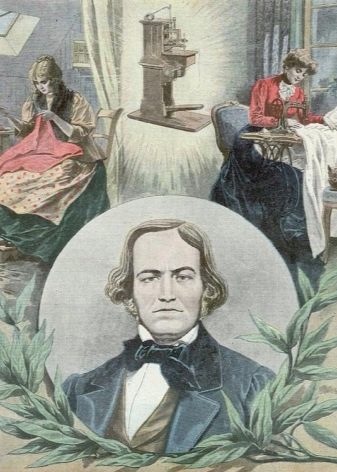

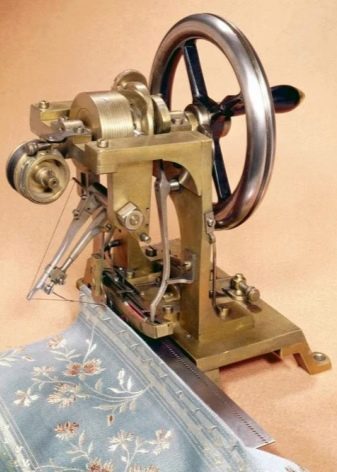

For several years, engineers in different countries began to think about how to use such a needle in obtaining a mechanized stitch. An official patent for a more or less close to a modern model sewing machine was issued in 1830 by Barthelemy Timonier.

This development has already allowed the creation of a garment factory. The next improvement was made by Elias Howe. This US citizen introduced the shuttle stitch to the world in 1845. This method allowed the machine to do up to 300 stitches per minute.

In the next few years, designs improved rapidly. Engineers tried to develop both horizontal and vertical sewing. The mass distribution of sewing machines is not in industry, but for domestic use, however, is already associated with the name of Isaac Singer.

The perfection of the products invented by him is such that they became antiques, and some of the pieces continue to regularly connect the fabric in the 21st century. The most successful of the earlier versions (with a “swinging shuttle”) was also introduced by Singer in 1850.

This brand earned worldwide fame by the mid-1860s. Until the end of the XIX century, there was a real boom in sewing machines, and then a number of companies appeared that are widely known to those who are interested in these days.

In our country, the production of this type of equipment started in 1900.

Now in the category of antiques include models:

- Borletti

- Butterfly

- Soviet "Seagull-2";

- "The Seagull-132";

- Csepel;

- Mini Jaguar;

- Adolf Knoch;

- Kochler.

The first sewing machines produced in the USSR date back to 1923. At that time it was a rather complicated production (about the same level as the production of cars today). Cost products accordingly. It is curious that the perfection of Singer's developments allowed them to be released unchanged for several decades in a row. Even the design was carefully preserved, which over time became a characteristic feature of Podolsk products.

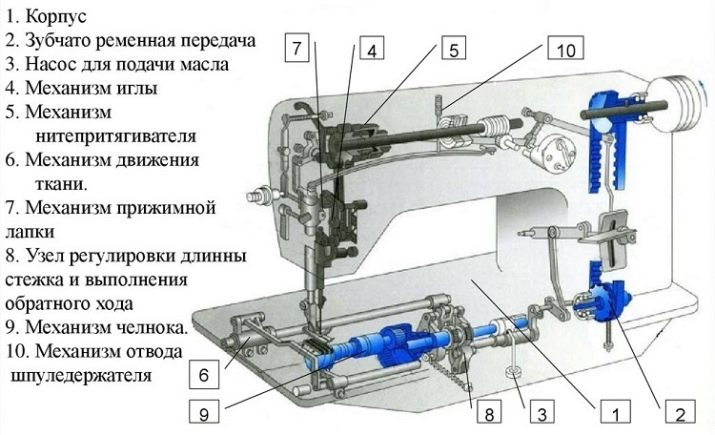

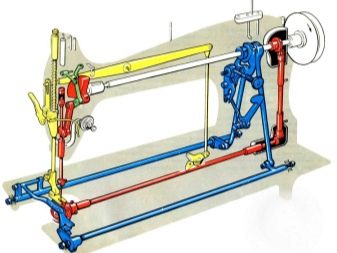

Principle of operation

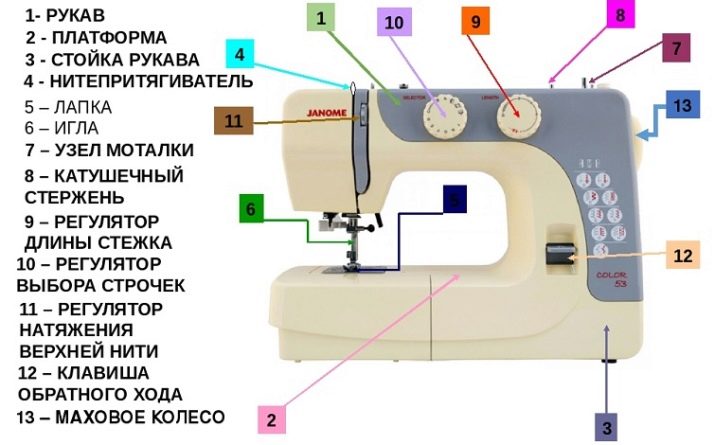

Over the past century and a half, sewing machines have been significantly improved. Not only electrified, but even electronic designs appeared. However, the main “core” has remained unchanged and, apparently, will remain in the same form forever. Both manual and motor-equipped devices always have:

- flywheels;

- winding devices;

- sleeves;

- needle holders;

- receivers (allowing you to reverse);

- stitch selection wheels;

- racks for sewing sleeves;

- plates for needles;

- special platforms.

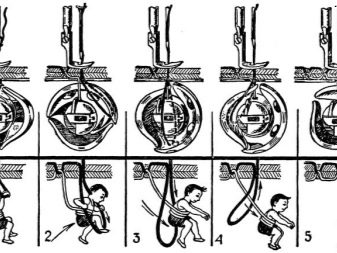

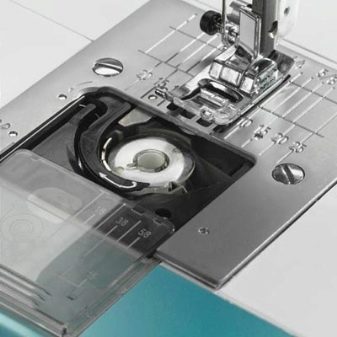

But all these details are easy to notice when examining the device from the outside. And the main part of any machine that works successfully is a shuttle. The most important part of the shuttle is the spool. It is on it that one has to pay constant attention when sewing. The role of the bobbin is the issuance of thread to the main nodes. This process is automated. It is required that the thread be inserted into a special slot. So that the system does not skip individual stitches, it is carefully tuned.

Continuing acquaintance with the scheme of the sewing machine, you need to pay attention to another detail - the nose. It avoids the spool falling out of the reel. The design is worked out and well balanced. Even deliberately violating it, not following the instructions, is almost impossible. Shuttle embed on a special profile. For its proper movement, a special connecting rod connection is responsible.

Operators have the opportunity to influence this connection using a metal pull-out panel.

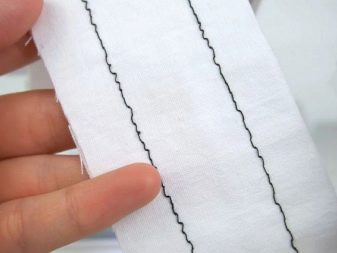

The needle, moving along a certain trajectory, passes down the captured upper thread. Then the thread takes the shuttle. With its help, the upper and lower threads are intertwined. Everything seems to be simple, but such an elegant solution already allows you to sew in a zigzag and even create chic patterns. Some models have side needles that simplify the processing of fabric around the edges, but it is almost impossible to find such machines in a regular store.

Inside the case of the sewing machine is a drive. In mechanical devices, it moves thanks to the muscular strength of a person. More advanced models use an electric motor. It is from the drive that the mechanical impulse arrives at the connecting rod.

All sewing machines are designed for long-term use, and therefore they try to make them as long as possible.

Lubrication is applied through special holes. Disassemble the car for this is not necessary. If you take good care of the equipment, it will easily last 40-50 years. Advanced options include the use of a foot pedal. Modern designers are increasingly trying to use not a mechanical, but an electromechanical pedal to further simplify the work.

A very important process of tissue promotion is implemented using the main shaft. A connecting rod connects it to the flywheel axis. Next, a pair of rods on the sides rotates synchronously.It is their torsion that pushes the pulling mechanism. One of the rods is complemented by a dovetail. It moves back and forth along the stitching matter. On the second axis there is a cam that raises and lowers the dovetail itself. He already transmits a mechanical impulse to special teeth. And these teeth rotate in place.

In the sewing machines there is another screw that controls the tension of the threads.

Types and their device

The main classification of household sewing machines implies their division into three types:

- purely mechanical devices;

- electromechanical devices;

- computerized systems.

Historically, the first type appeared before the others. Designs of this kind reached the peak of perfection by the beginning of the twentieth century. But on such, and even on older machines, you can sew well. The main thing is to correctly debug the device. Mechanical “Singer” and slightly newer “Podolsk” are mainly used for straight stitching.

Different models can have manual or foot drives.

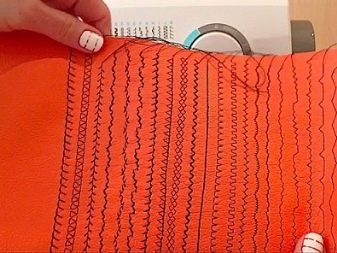

Better “mechanics” can even make a “zigzag” line. This is typical for models from the Seagull family. Mechanical cars are almost eternal. But such devices cannot boast of great functionality. In addition, they need to be separately adjusted for all types of fabrics.

The vast majority of modern sewing machines are equipped with an electromechanical drive. Such an addition significantly expands the number of manipulations available. You can easily:

- darn;

- hem the buttons;

- to form seams of various types;

- set the necessary line by scrolling the special wheel.

Computer sewing machine more functional and sophisticated. All such models have a built-in microprocessor. Provides for embedding the screen. The number of operations can be more than 100. The automatic system gives tips for selecting fabrics and determining the pressure. Many such models are in the assortment of firms Brother, Bernina.

The cost of such equipment is high, but this board is compensated by the ability to perform very complex manipulations. The most expensive versions have an embroidery unit and can remember the sequence of actions. Such a solution means a qualitatively new level of assembly. And the components are subject to very high requirements.

It is customary to distinguish between shuttle and chain machines. Some industry studies show that share shuttle technology accounted for at least 75% of all work performed.

If you plan to work with skin and similar strong fabrics, you should give preference core machine.

Such devices are very much appreciated in furniture and shoe production. But for home use, their capabilities are redundant.

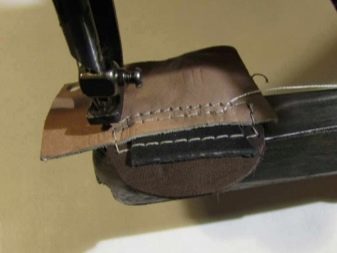

Deserves attention and sleeve modification. Contrary to the name, it is needed not only when working with outerwear. Such machines allow you to flash leather shoes and blanks for it in hard to reach places. It is also possible to work with bags and leather goods. It is noted that sewing machines with a sleeve platform are suitable for home use. This option simplifies work with sleeves, trousers.

The sleeve differs from the usual platform only in that it is possible to remove the storage of accessories. But we must also take into account that all mass-produced models now have such a platform.

Therefore, mentioning it in the description is nothing more than a clever marketing ploy.

Binder machine, unlike the traditional one-liner, it is quite useful. It is often used when you need to sew trousers or a dress. Such a device allows sewing according to the allowance, without going to the front side.

Some versions have an interval block, thanks to which the binder comes with a puncture through 1-2 stitches. The purpose of this gap is to reduce the noticeability of punctures on thin tissue.

Two-plunger (having a pair of extruders) apparatus makes it possible to form lines completely sealed between the main part and the stock allowance.

To work with elite costume fabrics, machines are used that make loops without a visible line.

If not limited to serious servo technology, you can give preference to mini-stick (in another spelling - mini-stachera). The purpose of its use is the repair of small products. And not only small ones, but also curtains and bedding. The mass of mini-sticks is from 0.1 to 0.3 kg.

This allows you to use them in road conditions - in a hotel, camping; carry with you in a car or car calmly.

Stitchers are very simple in design and usually do not have electronic components. You do not need to have any experience with stationary devices to use the road machine. At the same time, it will be possible to fulfill all the most frequent sewing and sewing options. It is possible to work with a wide variety of types of fabrics. The basic connection principle is the same as the stapler. If we return to stationary sewing machines, then among them should be distinguished models with a plastic and a metal case. The first type is easier. But the second is more reliable and more stable. All old models are made only of metal and wood. There is still a difference in the number of needles.

The one-needle machine has too meager capabilities. Even for home use, you often need to use a two-needle model. It allows you to keep a couple of parallel lines. You can also:

- scribble allowances;

- produce belts;

- handle belts and straps.

Often in the descriptions of sewing machines mention about the upper conveyor. This is called the “walking foot” (replacing the regular presser foot), which helps to advance the fabric from above. As a result, two folded layers of matter move simultaneously and uniformly. Folds and other consequences of uneven processing disappear. Also, the upper conveyors are relevant when you have to process thin sliding material.

They deserve a separate conversation tacking machines. They form short lines (stitches) - hence the name. Such devices can be both automatic and semi-automatic. The process is very simple: after applying a single-line stitch, it is entwined with an additional thread or threads.

Some models are programmed and can perform fairly complex processing options, and even automatically cut the remaining threads.

Complete the review appropriately at buttonhole sewing machines. All such models can automatically lay simple and eyelet eyelets. Often, the control of the sewing cycle is entrusted to the mechanical device itself. But in more advanced versions there is software control, significantly expanding the capabilities of garment workers. There is, for example, the option of creating loops with a reinforced frame, which is very important for easily damaged and knitted fabrics.

How to choose?

Shuttle Type

It is impossible to choose a good manual or automatic sewing machine without being interested in the features of the shuttle. For beginners, just mastering the art of sewing is certainly suitable pendulum device. A similar constructive solution was used very actively in the past. Now it can be found only in products of the budget category. But even they are significantly improved - now there is no need, as on the same Podolsk, to manually configure the system.

Double Shuttle Vertical Shuttle - the opposite of the “pendulum”. So much so that this device can only be found inside expensive professional models. It is valued for its combination of impressive speed and wear resistance. When using such a system, even intensive work is extremely rarely accompanied by the appearance of defective lines.

Horizontal shuttle - The most "quiet" and is mainly found in mid-range devices, however, it requires complex settings.

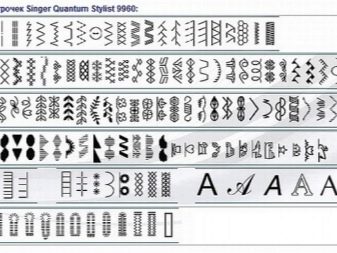

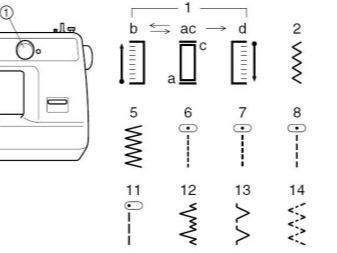

Types of lines

This point also cannot be avoided when discussing the technical characteristics of sewing machines. Single-zigzag zigzag allows you to process the surface of the slices.Narrow zigzags help grind the details of elastic fabric and knitwear. A double-stitch zigzag helps stitch the braid and connect its edges. The secret stitch mode allows you to flash the bottom of various products; this requires a special foot.

May also be present:

- decorative seams (such as shell);

- elastic secret course;

- three-row "stretch";

- cell line;

- connecting line;

- some other modes.

Loop execution

High-quality sewing machines of mechanical and electromechanical type can only make flat loops. It is difficult to implement something radically different on such an element base. The exception is computerized equipment and domestic embroidery mechanisms. In large factories, loops are formed using specialized looping machines, but they must be chosen by trained engineers, so this topic should not be addressed here.

The vast majority of household appliances already knows how to make loops in automatic mode. It is only necessary to monitor the translation of the foot and the length of the turns. When choosing the size of the loop, you will need to orient yourself on the button fixed in the foot.

Some models have different zigzag stitching speeds when going back and forth. But the presence of such an option must be clarified before purchase.

Type of control

Mechanical designs are completely independent of the power grid. Therefore, they can be used even where there is no mains power supply and is not expected. Electromechanical devices can no longer work without being connected to the mains. To set the required mode, special handles are used. In electronic sewing technique, buttons are used.

But a more advanced solution is to use sensors. In a number of stores, electronic cars are called cars that have separate mechanical buttons. It is also necessary to distinguish between software and computer control. The latter option involves using the machine own operating system. This solution is optimal for designer and designer sewing.

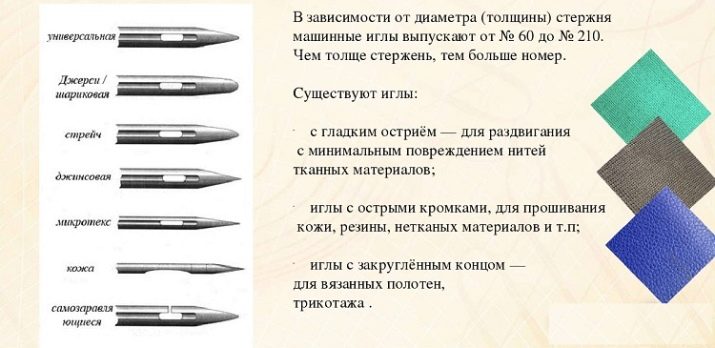

Needles

No matter how good the machine itself is, without needles it is completely useless. Well, as a stand, it can only be used. Needles are trying to distribute the preferred types of tissue.

Numbers 65-90 are perfect for flashing elastic and especially elastic fabrics. Light fabric will have to be sewn with 60-70 needles.

There are also such optimal combinations (by needle numbers):

- 80-90 - calico, staple matter and synthetics;

- 100 - denim and dense synthetic fibers;

- 110 - dense grades of wool;

- 120 - coarse cloth and sack cloth;

- 100-200 - leather, tarpaulin.

Additional options

In the past, there were 22 class sewing machines. They have long been discontinued, but 1022 class has already replaced. Such a solution is perfect for the atelier and for small sewing factories. The symbol for this and other classes is just a derivative of the base model. The main characteristics are as follows:

- 97th grade suitable for costume fabric;

- 852 class - the same purpose, but with a couple of parallel lines of the shuttle stitch;

- 51st grade - a frequently encountered, albeit slightly outdated, type of equipment.

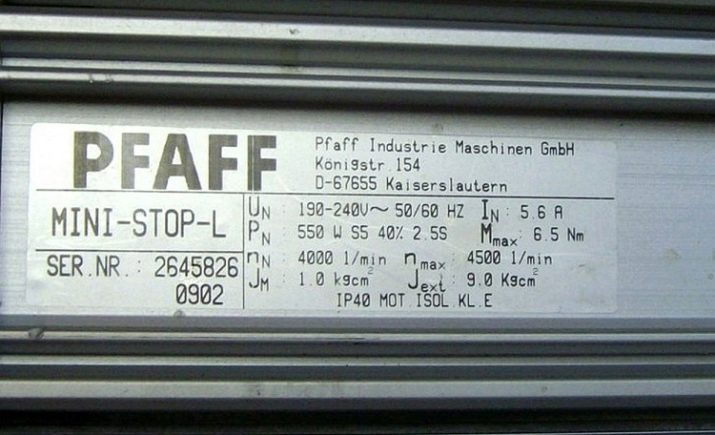

Perhaps the most important feature of the sewing machine is its power. It determines, among other things, the suitability of the device for heavy tissue. Moreover, the amount of payment for housing and communal services also depends on the power of the electrical device. The power on the nameplate is always indicated along with the backlight devices and control electronics. Therefore, the real force developed by the motor will always be less than the specified value.

Of the other points to consider when choosing, the most noteworthy are:

- preferred types of tissue;

- the greatest length of stitches;

- zigzag width;

- automatic or semi-automatic loop execution;

- internal needle threader;

- spot tack;

- needle positioning.

Popular models, reviews about them

Very popular now are Japanese cars of the brand Janome. For example, we are talking about the model 18E. The index shows that she can deal with 18 operations at once. Equally important is the high sewing speed (up to 400 beats per minute). The design is optimized for light and moderately dense tissues. The reviews point out simplicity and suitability for popular works.

Kohler - An old German brand of sewing machines. It was once very popular. But now it is of interest not as a practical product, but as antiques. A relatively interesting model is the Zick-Zack, which is cheap.

But users say that it is only suitable for those who master the art of sewing.

Typewriter Zimber in general, it works and does its job well. ZM-10918 can be powered by both batteries and mains. Problems arise when sewing thick denim. But its thin version, this device will "take" calmly. The model is designed for calm thoughtful work. It justifies its price.

Products are also in demand Gemsy. An example is the single-needle, straight-line model GEM 8900H. She will help out those who want to work with dense and moderately dense materials. The automatic lubrication option is attractive. Users approve of this model, but point out that its assembly is a little difficult.

Leader agat - Another good sewing machine. She can flash all fabrics found in everyday life. Build quality is not satisfactory. Handling is also not too difficult. Reliability is up to standard.

Sewing machine DEXP SM-1200 relatively light and looks good. But she has no speed control. The source of energy is batteries. Therefore, the device is suitable where electricity is often turned off. Ideal for sewing and simple work, but nothing more.

Company products deserve a separate discussion. Velles. She has been supplying sewing machines for about 20 years. Basically, the product is intended for industrial use. It is worth considering that in some models the rods are not reliable enough. Handle them with care.

Radom 86 - Another "hello from the old days." The model is able to give a straight line up to 0.5 cm wide. The manufacturer provides for the use of I20 grease and its direct analogues. The quality of work is generally acceptable. Nevertheless, experienced craftsmen should look for something newer.

Complete review of modifications appropriate on the brand "Lada." 237th version it has a programming device. The products of this brand were manufactured in Czechoslovakia. The design is very reliable, there are instances that have worked for several decades and retained functionality. It is noted that "Frets" sew relatively thin skin.

Terms of Use

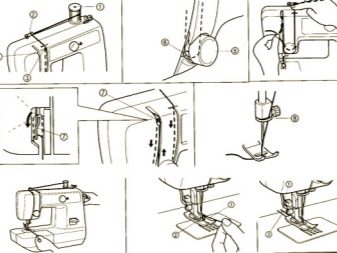

The most important points on how to use any sewing machine are given in its instructions. It describes how you can:

- overcast the edge;

- thread a thread;

- make setup.

All these actions are more or less individual. Experienced sewing machines can change the device relatively easily. But the main thing is not this, but the general principles of working with sewing equipment. In the vast majority of models, the start button is located to the right of the operator’s seat (which is quite logical). But regardless of this, the machine must be on a stable support.

Before starting work, you need to sit in a comfortable chair. The needle should be to the left, and all other parts to the right. Insert the needle as securely as possible, that is, the plane back. The thread is wound by placing the spool on the upper holder. In this case, the fiber should pass through the thread take-up and get on the bobbin. The edge of the thread is left outside to insert it into the needle. Part of the information is usually given not only in the manual, but also on the typewriter body. These tips should also not be forgotten. After finishing work, be sure to clean the device and put it in order.

It’s better to start training on low-quality low-quality material. It is easier and calmer to work with him.

Do not operate the sewing machine:

- on open air;

- in an unheated room;

- in damp;

- surrounded by caustic and explosive substances.

On mechanical devices, you must carefully monitor the sewing speed. It is undesirable to save on needles and threads - even first-class equipment can create problems because of them. It is strictly forbidden to bring your fingers, face or other part of the body closer to the needle, thread the thread into an operating machine.

You can work on electrical devices only after checking their insulation and grounding.

Possible problems

Even the best technique sometimes fails. When it does not capture the bobbin thread, the cause may be:

- dullness of the shuttle nose;

- incorrect needle bar calibration;

- nonsynchronism in his work and in the actions of the needle bar;

- burrs on the spool cap.

Missed Stitches - a sign of poor quality of the needle or a large gap from it to the shuttle. If the machine collects the threads from below, breaks them, you will have to adjust the tension. In more complex cases, you need to work with the shuttle, the mechanism moving the tissue.

Also, people face such problems:

- improper assembly of tensioners;

- mismatch of needles and threads;

- loosening bobbin case locks;

- corrosion;

- uneven winding of threads.

Review Reviews

Janome 2323 is great for home use. It's a simple but powerful machine. Experienced craftsmen “for themselves” can also sew on it. Quality will not be lost.

Also praised:

- Necchi Comfort 7434 AT (for work with delicate and beautiful fabrics);

- Brother Comfort 35 A (for quality and elegant appearance);

- Singer 7467 Confidence (for the excellent balance of price and quality).

Tips

Other things being equal, cars with an LED lamp are much more practical and even more economical than models with traditional incandescent lamps. Such a light source also eliminates the appearance of burns. The binder allows, as its name implies, to optimize the border and speed it up. The choice between branded and mass-marketed edgers is largely a matter of personal taste and budget. There is still no practical difference between the two.

If you plan to carry the sewing machine often, it’s useful to get a bag where you can put it and accessories. The same bag is useful for safe storage, if you plan to sew only periodically. It is very important to use only those oils recommended by the manufacturer for lubrication.

If the needle plate fails, it is best to change it. Attempts to ignore the problem or repair this part yourself are rarely productive.

Find out how to choose a sewing machine and what sewing operations you really need in the next video.