Woodwork looks beautiful and unique and includes many different techniques. One of these is slotted thread. Its feature is that the pattern is cut through and through. Because of this products seem very light and lace.

Features

The history of this technique has several decades, but it does not cease to be popular.

Most often it is used to decorate home furnishings, namely: window shutters, platbands, railings, arches in the house, tables and just decor elements. Caskets, coasters and much more are also decorated with carvings.

A feature of this technique is the absence of a background under the pattern. Therefore, the slotted thread in the description is sometimes referred to as sawn, through or openwork. Despite this, craftsmen can attach a background canvas of a contrasting color to make the details more expressive.

Carved thread will suit both beginners and experienced craftsmen, as patterns in this technique have different levels of difficulty. It can be either ordinary geometric shapes, or complex curls, floral ornaments, animals and birds.

Kinds

Carved thread can be of different types.

- Flat top. A type of thread in which all elements of the pattern are at the same height and on a flat background.

- Embossed. This thread is performed in such a way that the entire surface is a pattern, it is not flat. In this case, at the end, the background is removed to get a through view.

The slotted thread itself, as mentioned above, is divided on openwork (without background) and invoice (with background).

Instruments

You can perform slotted threads with completely different tools: jigsaw, saw, chisel, knife, blades, milling cutter, drill and other. The appearance of the work, its accuracy, the development of details, as well as speed, will depend on the choice of the tool.

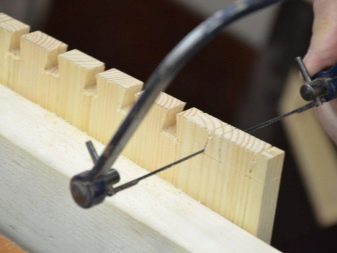

The most popular are drill and saw, which can be of different sizes, depends on the pattern template. In this case, you first need to make a hole in the workpiece with a drill, to place the saw blade or jigsaw in and not to cut on the edge of the wood.

To make the edges of the cut look neater and nervous, you need to take saws with smaller cloves or treat them at the end with a grinder or sandpaper of a small abrasive.

Unlike carving with a jigsaw, working with a hand tool will be slower, but you can concentrate more on working out the details of the pattern according to the pattern.

Also can use electrical appliances - jigsaw, the use of which speeds up the process, but requires caution, - or apply laser cutting. This technique is not very popular, because it requires quite expensive equipment, although the speed increases. Its use is resorted to only in the case of large-scale production, when it pays off.

Electrical appliances also apply. milling cutter which you can perform a large number of different techniques, since you can install various nozzles on one tool. You need to get used to working with an electric mill, so beginners are not recommended to use it.

The process of sawing a pattern can be lengthy. Usually, those parts of the work that larger tools could not handle do the milling cutterFor example: working out the smallest details, rounding corners or grinding edges. The use of an electric milling cutter is possible at all stages of work, but it is irrational, because the tool engine is not always designed to operate for a long time in a powerful mode, and nozzles that will quickly grind will often have to be changed.

An interesting slotted thread technique burning. It is performed using special equipment, a very hot wire or nichrome string. The disadvantage of this technique can be considered a strong burning smell, so you have to work in a special room or in the open air. The tool needs to be cooled often, and because of this, the work process can be delayed. Also on the edges of the pattern may remain a charred edge.

Materials

The final result of the work is also very dependent on the material on which the thread will be made, since the wood differs in density, structure and environmental resistance.

Slotted threads can be made on plywood or pure wood.

Therefore, we will consider both of these options.

If you choose plywood sheets, then you need to know that they are of several types.

- Plywood FC - moisture resistant material that is convenient to use and harmless to humans and the environment. It is used to perform almost any type of work.

- Plywood FB - material that undergoes additional processing, after which a protective layer appears, allowing it to be used on the street. Because of this, the cost of the material may be higher. It is also harmless to humans and the environment.

If you choose wood, you must consider the characteristics of each type of tree.

Novice masters are advised to use birch or linden, because these varieties have sufficient density. The tree structure is dense, therefore, it will be convenient to work on it small details of the pattern.

Aspen is less suitable for beginners, because in the process, the wood is wrinkled and it is very easy to cut. You need to get used to the processing of this variety.

Fir, spruce and pine they are used most often because it is easy to find them, and the cost is low.However, it should be borne in mind that these varieties have different layer densities and a pronounced structure. This may interfere with the creation of a small picture.

The wood must be dried before workso that in the future it does not crack and does not bend. Therefore, this training point cannot be ignored. If you have not purchased enough dry material, you need to dry it yourself. Place the board on the end so that air enters from all sides.

Technology

When all the preparatory steps are completed, you can proceed to the threading process itself.

- A pre-made pattern template on paper is firmly attached to the workpiece.

- After that, you need to transfer the drawing to the tree with a pencil. You can not use a template and come up with a pattern yourself, create your own drawing.

- Next, holes are made in the tree in order to insert a jigsaw.

- After completing the pattern, you need to completely process the edges by polishing them.

- The finished product is varnished. Spray painting will facilitate the process and save the product thanks to the uniform application technology.

How to make wooden platbands for windows with slotted carvings do-it-yourself watch in the video.