Hand carving requires a lot of time and effort. Progress does not stand still - wood processing machines and the creation of both simple products and those requiring high precision were created. Let's consider what woodworking machines can be used both in production and at home.

Features

Depending on the type of product, different machines are used.

- Sawing machines are used to shape the wood. A circular or band saw is usually used.

- After cutting it is necessary to cut off irregularities. It is carried out using a planer or planer.

- Various holes can be cut thanks to a drilling machine.

- Turning allows you to make products that are figures of rotation.

- Grinding gives products a neat appearance and smooths out bumps.

On sale usually found manual and electric machine tools. The latter are widespread due to their functionality and ease of use. However, you cannot do without hand tools - these include knives, saws, chisels and machine tools.

Manual

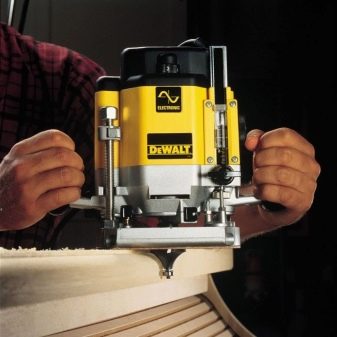

There are two types of manual milling machine.

- Submersible - lower the cutter from above into the material and drive in the direction of the given path of the template or ruler.

- Edge milling machines are not able to immerse in the material; all milling parameters are set in advance. Depth is set, a parallel emphasis is fixed, the bulk of the work is done along the edges.

Milling cutters can be divided into 3 power levels:

- low power - 500 - 1200 watts;

- average - 1200 - 1900 watts;

- high - 1900 - 2400 watts.

Low power milling machines convenient for working at home, they are compact, multifunctional.

Cons - work can be done with material up to 32 mm, there are also restrictions on the length of the cutter, they are mainly equipped with nozzles of 6-8 mm.

It can be used for the manufacture of caskets, small coasters, frames and other things.

Medium Power Milling Machines - These are more powerful machines, capable of solving tasks more difficult. Cons - inconvenient to use on small parts. Work with 8-12 mm cutters, 6 mm are rarely used. It can be used for the manufacture of stools, shelves, tables or stands for flowers and similar items.

High power milling cutters needed for large-scale work, volumetric parts of furniture and other overall structures. The advantage of such milling machines is the use in an inverted form, having made a lateral emphasis, and the product can be manufactured as on a milling machine.

What features to consider when choosing?

- The working vertical entry is 40-50 mm, 50-60 mm, 60-70 mm (respectively, increasing power).

- There must be a speed controller, slow start.

- Ability to work with copying devices.

- Dust removal system.

- Milling depth limiter.

Pay special attention to the choice of cable, it is convenient to take the option with soft rubber long enough not to use additional tools.

Backlash of a milling rack must be stable, do not tilt when supporting. Otherwise, the work will be unsafe. Also pay attention to vents.

Exist devices for manual wood processing. Electric chisels - This is a new generation of devices. The use of these devices is usually at the household level. This versatile tool has replaced the hand chisel. Due to its compactness and light weight, the model is very popular. You can adjust the speed, in the main models there are 3 of them, as well as power, given the softness of wood and the subtlety of work.

The unit is used for woodcarving, cleaning surfaces from various irregularities and contaminants, for cleaning glue and paint. It has many different nozzles, suitable for the size and density of the material.

It is also used to perform engraving on a wooden surface, to create unique patterns and ornaments. You can create unique souvenirs made of wood. The electric chisel is convenient and safe to use.

Desktop

Machine tools for fine and precision carving can be used both in production and at home. The best option for working at home is considered wood carving drill, which allows you to drill the product at any angle. Small size and ease of use allow you to perform work quickly, accurately and accurately.

For making souvenirs it is better to use milling and engraving machine. It connects to the computer thanks to the CNC (numerical control), and then performs the work independently. Can also be used in industry. copy milling machine, which is used to cut 3D shapes from wood, or laser machine. Its peculiarity lies in the fact that the tool is equipped with CNC, which can be found a bit below.

Computer controlled

Innovative machines allow you to perform precision tasks. 3D machines with CNC equipment are used most often. The simulation process is done on a computer. Then a memory card with a 3D model is inserted into the machine port. Further, the machine operates by itself, without operator intervention. Sometimes after manufacturing a workpiece, manual grinding is required. 3D machines can be both domestic and industrial. Households are much smaller and lighter than industrial ones. The possibilities of using industrial are very versatile and almost limitless.

The advantage of 3D CNC machines is the speed of production, reducing the price of the product, the repetition rate for a given program for the production of parts.

Thus, it became available to quickly and high-quality produce parts for interior elements - carved furniture elements, icons, frames for watches and mirrors, handrails, legs and many other details.

Homemade cutting tool

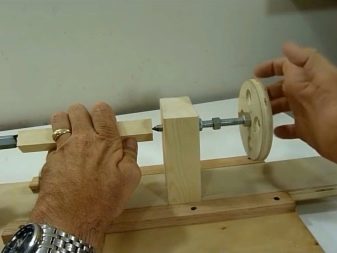

For the manufacture of the machine at home, certain details will be required, we will consider them according to the list.

- Bed - can be assembled from metal profiles, you can use wooden blocks. The main thing is to ensure rigid fastening of the supporting elements of the precast machine.

- The headstock is used to mount the motor shaft, as well as the driving center, is stationary. It serves as a base for the placement of the main rotation unit. Thus, the engine and plan washer are the leading center and headstock. Through the leading center, the rotational movement is transmitted to the workpiece, the tailstock must freely change position.

- The master and slave centers should be located at the same level. Three conditions are mandatory - alignment, fixation and rotation. The driven mounting center is made with a cone-shaped tip and should easily move around the frame, taking into account the dimensions of the workpiece.

- The electric drive must be with a speed regulator axis of rotation. The leading center necessary for securing the material for processing contains a blank. There are 3 ways for the lead center - a plan washer, a cartridge and a trident.

- An emphasis for a hand-held cutter, which should be made of thick-walled iron and very well fixed, that is, after setting the desired position, should also provide a rigid fixation of all supporting elements.

Can be made mini woodworking machine. The simplest consists of three parts: an engine, tailstock and a handyman. The engine is suitable from an old washing machine, an engine power of 180 W (W) and 1,500 rpm will be sufficient for domestic needs. The leading center of the machine can be made from part of a metal water pipe, you only need to choose a diameter suitable for the motor shaft. The handrail is attached to the table with a fixing screw from the bottom to eliminate protruding parts.

Need to check ease of movement in all planes, the hand must be movable and fixed at the required level and position. For this, replaceable guides of various widths are used. So, fasten the engine on the left, the rear beam on the right, the handle in the middle, fix the part for processing, and you already have a whole DIY workshop! In work on woodworking machines important safety precautions - use headphones, goggles, turn on ventilation and a dust bag. Of clothing, a protective vest, gloves and an apron are required.

The operation of a CNC milling machine for wood processing is shown in the following video.