The master carver always seems to be a brutal man who works in the workshop. And shelves and boxes with numerous tools surround him. Today, gender equality in woodcarving, although it has not become 100%, but women are also actively occupying this niche, since the demand for wooden decor is great. This means that there are more newcomers, and their questions should not remain unanswered. The most basic ones concern the choice of tools, the initial set of chisels.

Features

Chisel is a multifunctional tool. In the dexterous hands of the chisel carver, he can do a lot: choose an extra volume of wood, climbing into the most difficult-to-penetrate zones. She can even align the edges of the furniture. A chisel can round off any radius and, finally, make an artistic composition out of faceless wood.

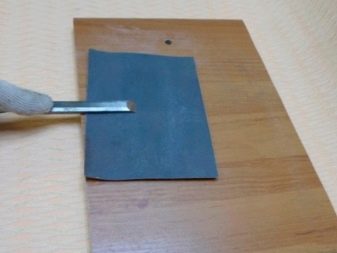

By the way, she can work not only with a tree. It copes well with soft metal, successfully interacts with plastic and leather.

And if the master decides to reprofile, a set of professional tools can still be useful to him.

By functionality, the chisels can replace the bit. But there is some difference in them: the chisel has a smaller amount of harvested wood, since the cutting edge of this tool is narrower than that of the chisel. The parameters of the angle of the cutting edge are also different. Chisels are divided into carpentry, art and machine tools. Chisels for woodcarving - a variety of options for cutters that differ from each other in the shape of the working area. For example, a straight working part will allow you to get smooth edges at the output along the entire perimeter of the wooden workpiece, and an oblique working part helps to choose narrow grooves and get angular edges.

Semicircular and round working zones form radius curves and spherical fragments. These chisels, by the way, are often called calms. But the corner working part helps to design blind holes of non-rounded cross section. Finally, the curved working area copes with undercuts and spherical fragments. Each master picks up chisels and knives for himself. And although almost everyone has the basic tools, you need your hand to feel the tool. And it is always an individual choice.

Two cutters will need different chisels (in design, notches) to form the same part, and this is normal.

Kinds

As noted above, the shape of the blade itself plays a decisive role in the chisel and its functionality. Here are the types of popular chisels.

- Straight chisel knife. Such a device is indispensable for machining carpentry workpieces and cutting through simple recesses.

- Corner Chisel. It resembles the English letter V, at different angles in the chisel there are two contiguous planes of the blade. It is logical to assume that such a variety was created to obtain V-shaped recesses. The sharper the cutter angle, the deeper the notch.

- Slanting. The blade of this tool is beveled at 45 degrees. Longitudinal grooves are cut with this professional chisel. It is suitable for primary changes in the workpiece.

- Semicircular. It will prepare the product for processing. She is also able to cut out all sorts of ornaments, make serifs. It happens round, medium and sloping. A semicircular tool stores each cutter.

- Klukarza. Outwardly, it is very similar to its predecessor. But the working surface of the klukarza is equipped with a rounding both on the shaft and on the end part of the blade. Thanks to this form, you can count on the smooth movement of the tool on the tree. Klukarzy have subspecies. For example, the cutting part of one klukarza is rounded, the other is straight, and the third is coal.

- Shtiheli. Made of mushroom-shaped handle and oblique incisor. Serve, as a rule, for the formation of grooves. The more the carver presses the tool, the brighter and deeper the thread will be.

- Caesarics. In a sense, this is also a semicircular chisel, but its working area is very narrow, only 3 mm wide. Caesars make narrow grooves and work out the smallest ornamental fragments.

- Rivet. Such a cute word is called a mini-chisel with a perfectly sharpened narrow blade resembling a sharp leaf. You have to use a buckthorn in a situation where simple chisels are powerless. Fine work, accurate drawing - for this, a small chisel is acquired.

- Marigold. Another mini-tool that cuts the finest fragments, but more rounded.

- Reverse chisel. It features a convex outer recess to create a protruding pattern on the main planar canvas.

And they also make chisels forged, die-cut, stamped. The forged ones have a noticeable thick blade, so they can be hardwood. Cutting incisors are suitable for interaction with medium and soft types of wood. The stamped chisels work thanks to the thrust washer.

Homemade chisels are not nonsense.

Nevertheless, in ready-made prefabricated samples, the tools already lie in a certain configuration, and not all of those presented are necessary for the cutter, not all are provided for in the set. Therefore, home-made chisels appear often, and in quality they may not be inferior to factory products.

The modern carver has a great choice - from curly chisels to electric ones (and there are such). But the basis of the craft begins with the simplest, most recognizable, well-established chisels from the finished set. Having gotten to work with them, it is already possible to master any such, even the most complex carved tool.

How to construct a chisel yourself - what to take for a blade:

- metal cutter - it is quite rigid and responds well to sharpening;

- file - for a carpentry chisel, quite a worthy source;

- drills (for metal) - a decent base for narrow little chisels;

- profiled tools - suitable for a corner cutter;

- needle files - will execute a thin instrument.

A small tool is better at home. The handle is often made of timber, since wood is more familiar and environmentally friendly than plastic.

How to choose?

I want the material to be durable, and the cost of the set does not go beyond the budget. We have to make some compromises. Some prefer to order a ready-made kit from an Asian site, others choose chisels one at a time, long and reverently composing their own collection.

We will give tips for beginners on choosing chisels.

- A truly high-quality blade is made of tool steel type 13X or 8XF. Such a metal has a high carbon content, while chrome, sometimes tungsten, is also present in it. The type of steel you should definitely pay attention to when buying, otherwise you can overpay for not the highest quality.

- Chisel hardness values should not be lower than HRC 59.60. If they are smaller, then you have to buy a cheap chisel (maybe just a fake) made of structural steel 45X. What is bad is that you will have to sharpen the tool very often.

- If you don’t have time to go and choose tools incomplete, you can buy a set. Among the most popular ones are Narex, Sandwik, as well as Bahco. Among the products for carvers there are a lot of good Japanese brands, and from Russian it is worth taking a closer look at Enkor.

- As for the optimal length, it will be 10-15 cm. If the cutter is larger, it will withstand less load. The handle of the chisel can be wooden and plastic. On the one hand, the tree is more familiar, its naturalness is tactilely more pleasant, on the other hand, good plastic can be more durable and shockproof. Therefore, the issue of choosing the material of the pen does not have an objective assessment.

- If the manufacturer is not indicated on the product labeling, it is most likely a fake. And no matter how attractive the fake price may be, they will not justify even those small funds that were spent on them. Good chisels will last for years.

- The quality of steel chisels is easy to test on a grindstone. When the steel is properly hardened, burrs will form during sharpening, they can be easily removed. But if there are no such barbs, then the material is overheated and the cutter is banal dangerous. If burrs form, but it is impossible to remove them, this means that the steel is very mild. She just can not stand the sharpening. The pointed edge of such a chisel will deform even with mini-effort.

You need to understand that any chisel on the chamfer appears burrs and bumps.

They can be adjusted on the grinding wheel. The master holds the deformed bevel near the circle, removing bumps, rust and chips. A three-level whetstone can give the chisel any sharpness.

How to sharpen?

Thanks to competent sharpening, the cutter acquires an accurate cut and ease of operation. But it’s not the sharpness of the blade that matters, the sharpening angles also matter. They are dependent on the type of instrument and the actions that will be performed by it.

If the cutting part is sharpened correctly and the chamfer angle is maintained, then the chip cutter will be easier to withstand its thickness. And the applied efforts also correlate with the quality of sharpening.

You can sharpen the cutter with both manual devices and drive ones. Basically, craftsmen use grinding stones and whetstones wrapped in sandpaper, sheet abrasives. Polishing bases made of felt and fabric are also suitable for this mission. Of course, grinding machines are also used (they are vertical and horizontal).

Here are some key points to sharpen your tool.

- The value of the angle of sharpening is an interval of 25 +/- 5 degrees. Such parameters are formed by GOST 1184-80. Usually the angle at which you need to sharpen the tool is mated to the thickness of the chisel. Thick blades are often oblique.If there is only one chisel, it is recommended to sharpen it at a working angle of 25 degrees.

- In the basic configuration for sharpening there are 3 items - an abrasive for starting processing, grinding materials for fine-tuning, and also a sharpening mandrel that fixes the angle.

- If the device is manual, the angle in it can be set with wedges, if the factory one - there is an angle adjustment in it. The device is simple: the carriages move the abrasive over the surface and the inclined platform, and the clamp is pre-set at the right angle.

- The chamfer is sharpened both manually and with a power tool. But the fine-tuning of the cutting edge is really possible only by hand.

- Sharpening water stones are ideal for sharpening the blade of a chisel. First, these stones are soaked in water, during grinding it comes to the surface and is mixed with abrasive dust. Which forms a viscous thin consistency.

- Finishing and grinding are still different operations. The lapping sets the geometrically accurate plane of the chamfer, grinding provides an option for its roughness.

The algorithm for sharpening a chisel with his own hand is: First, the chamfer is ground on the abrasive block (no visible defects should appear), then the line of the cutting edge is checked (perpendicular to the tool blade). Then the block is wrapped with fine-grained grinding: the chamfer is polished to a shiny surface and maximum sharpness. After processing, the chisel is wiped dry, because the bar with sanding paper can be moistened with water. Both the ability to choose the right one and the perfect sharpening come with experience.

Therefore, beginners should not be afraid: the work is fascinating and creative, and the tools become literally an “extension of the hand” of the master.

The following video provides an overview of wood chisels.