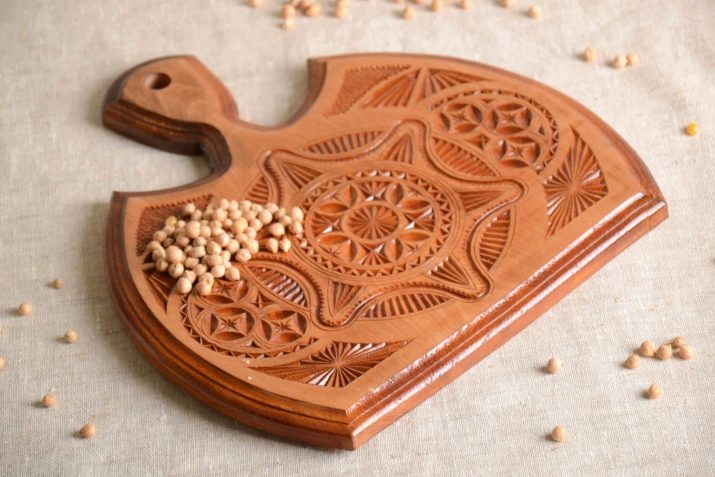

Each housewife in the kitchen has several cutting boards. Such a kitchen accessory can not only be used for its intended purpose, but also be an item for decorating the kitchen and complementing the interior. To give the kitchen a certain style, carved planks made of wood are most often used.

Kinds

Wooden cutting surfaces can be made of smooth polished wood, as well as decorated with carved patterns made by hand. All wooden boards can be divided into 3 types, which imply a method of their manufacture.

- Solid wood. With this method, a piece of solid wood with a thickness of 3-5 cm is sanded, given one form or another, the edges are treated and, if necessary, a carved pattern or pattern is made. Such boards have a lot of weight and high cost. Most often, solid wood is used by craftsmen who make boards manually.

- From glued wood. Such cutting boards consist of 2 or 3 thin layers of wood glued together. Similar models are manufactured at enterprises engaged in mass production. They have a low cost, are more susceptible to wear and bending during use.

- End cutting boards. Such solutions have a large thickness, they are very massive. Such boards can be recognized by the characteristic arrangement of wood fibers: they go perpendicular to the cut. End boards are wear resistant and are used for cutting meat. In addition, the knives used to cut the products on the end boards are less prone to dulling, as the blade of the knife slides along the wood fibers during operation without cutting them.

Materials

Wooden carved boards can be made of different types of wood, each of which has both positive and negative characteristics. Most often, cutting surfaces are made of the following breeds.

Pine

Such material is available, has a low cost. But because of the high hygroscopicity, a board made of pine will absorb a lot of moisture, gradually swelling and becoming unusable.

Alder

Such wood is considered the softest., therefore, woodcarvers most often work with it.

On alder, you can cut geometric, contour or sculptural patterns.

Linden

Linden products are also customary to decorate with carved patterns. Paint or varnish lays on this wood perfectly., therefore, lime boards are more often used as decorative gizmos than for their intended purpose.

Oak

Oak planks will be very heavy and expensive. On such boards do not use thread or pattern.

They appreciate the natural pattern of wood fibers, which is emphasized by coating the surface with varnish.

Birch tree

This breed is also used in the manufacture of cutting surfaces. But you need to remember that when in contact with water, the birch board will quickly darken and lose its neat appearance.

Beech

Is pretty durable and abrasion resistant material. However, beech is able to absorb moisture.

You should choose the instance whose surface is additionally varnished.

Larch

Most suitable for a daily plank. Such the material has great moisture resistancetherefore, after washing the board will not deteriorate. And thanks to the heat resistance of larch, the cutting surface can be used as a hot stand.

Shapes and sizes

Wooden cutting surfaces are characterized by a variety of sizes and shapes. The choice of model should be determined by purpose. And if you can choose any shape, size and color to decorate the interior, then To work in the kitchen, it is desirable to have several boards of standard sizes.

- Board size 30x50 cm Suitable for cutting meat, poultry or fish. It is better if it has a protective coating to avoid absorption of extraneous odors and excess moisture.

- Plank size 25x40 cm ideal for slicing cheeses, sausages, vegetables or fruits.

- Instance size 15x20 cm Suitable for slicing bakery products.

Shapes can also be different: there are rectangular, rounded models, planks with and without edges, products in the form of animals, fruits and vegetables.

Rules for selection and care

When buying a particular model you need to consider what it will be used for. For different products you will need different boards. For example, a meat cutting product cannot be used to cut fruit. Pay attention to the shape of the board, because you will have to work with it daily. The most convenient will be rectangular products.

It is important that the selected board has a protective coating. They are popular and bilateral models: on the one hand, there will be carvings, and on the other, ordinary wood intended for use.

Basic care for wood carvings consists in drying them completely after contact with water and thoroughly cleaning the indentations in the drawing. Wet wood can darken, bend, have an unpleasant odor, and due to food debris it can be covered with mold and fungus.

Using such a board will be hazardous to health.

You can find out how to make a carved cutting board with your own hands in the next video.