The quality of a haircut depends on the quality of a professional hairdresser tool. One of the important criteria is the sharpness of scissors and razors. In this case, sharpening must be carried out either in a specialized workshop specifically for hairdressing tools, or at home in the presence of a certain type of machine.

When to sharpen hairdressing tools?

There is no consensus on how often it is necessary to sharpen hairdressing tools - each master does this based on the frequency of use of scissors and their quality. He already “fingers” feels that the inventory needs sharpening. Beginning hairdressers are recommended to sharpen once every six months and more often pay attention to the condition of the blades. Criteria when it is time to carry the tool to the master:

- the cutting edges of the scissors have changed color;

- the blades are adjacent to each other with a gap;

- the blades are not perfectly smooth; they have nicks and burrs.

It is believed that after each sharpening, the scissors blunt faster. therefore The cutting master has his own grinder master, which provides professional scissors with the maximum allowable updating of the blades without loss of quality.

Thinning scissors are sharpened on one side as usual, and on the other, depending on its shape and size of the notch.

After the blade renewal procedure, nail clippers can withstand up to 150 clients, while “out of the box” nail clippers need to be sharpened after 10 uses.

Types of machines

There are several types of grinding machines.

- Hand held - the well-known "fish" or a household machine for sharpening scissors.

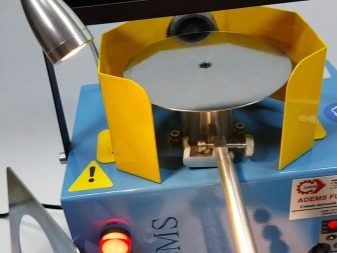

- Tabletop - small compact, weighing from 5 to 10 kg, costing from 2500 rubles.

- Professional - large-sized devices weighing up to 50 kg and costing from 40,000 rubles. As a rule, they are divided into machine tools for knives, manicure and surgical instruments, hairdressing scissors.

In turn, all machines are divided into subgroups according to the location of the faceplate, spindle speed, adjustment of sharpening angles (from 0 to 57 degrees), the diameter of the grinding wheels. For hairdressing scissors and blades it is better to use machines with a horizontal faceplateon which the grinding disc of the desired diameter and abrasive is installed.

On machines from Germany, laser calibration is often set - a sight on which even a novice master can easily set the required sharpening angle. And also on the equipment there is an exact adjustment of the speed of rotation of the disk, ensuring minimal grinding of metal from the blade. To protect the eyes from metal particles on the machine a visor is provided, to prevent their inhalation - a mask.

For professional equipment, the spindle runout rate should be only 0.11, and it is definitely prescribed in the technical documentation.

The optimal characteristics for the grinding machine are the presence of a reversible system for finishing the blades, the ability to put discs with a diameter of 150 to 240 mm, rotation adjustment up to 3,000 rpm, a motor with a good cooling system and low noise.

Can I grind with my own hands?

Scissors can be sharpened at home with even the simplest machine. The main criterion for straightening the blades is the required sharpening angle. Do not try to sharpen a hairdresser's tool at a minimum angle - despite the fact that it becomes super sharp, it will be possible to work with it only a couple of times. The smaller the sharpening angle, the sharper and thinner the blade, therefore, the tool blunts faster. Optimum - 45 degrees, if you plan to make the edge thinner, you must be sure that the blades are made of very high quality steel.

Micro-scissors are sharpened at the most obtuse angle of 55 degrees. Thanks to the notches on the blade, they cling to the hair and cut it perfectly. However, to edit such blades requires a special disk.

It is not recommended to sharpen convex sharpeners yourselfbecause it is difficult to repeat at home. In a conventional tool, the blade itself goes at a certain small angle, and then abruptly goes into an angle of 45 degrees. Here the border of the transition is clearly visible, and it is easy to repeat on the machine.

Convex sharpening does not provide for a sharp change in angle, it comes to naught smoothly from the very top edge of the canvas.

Instruction manual

If you have ordinary hairdressing scissors without micro notches on the blade, then you need to start with the diagnosis of the tool. Then it must be disassembled, cleaned and washed. The tool is washed with soap and dishwashing liquid. If a rolling bearing is used, water is washed strictly up to the screw group. Do not wash with washing powder - steel deteriorates.

Straightening (if required) removes curvature after falling or bent tips. After that, there is already no wear on the back surface of both blades. If necessary, it is worth grinding (honing) to eliminate microroughness. After this, rinsing and cleaning are carried out again.

Next is the transition to the front surface of the blades and they are polished, then the notches on the leading blade are removed, its correction and polishing are done. Next to it is the leading edge of the driven blade.

After sharpening, the scissors are lubricated and reassembled. At the end, the course of two paintings relative to each other is adjusted.

The angle of sharpening in degrees for convex blades is 30-45 degrees, and for straight lines - 45-55 degrees, it is determined using a special device.

See how to sharpen scissors below.