The garment steamer is very popular because it is convenient and functional. But such units sometimes fail, so you should study the types of malfunctions and the intricacies of the implementation of repairs at home.

Device

Garment steamers are made to process products with steam. The second name of such an aggregate is steamer. The steamer works the same way as the iron - with its help it is possible to smooth creases and folds on clothes with the help of water vapor. Due to such a device, you can easily solve some problems that are beyond the power of the iron. For example, smooth small wrinkles under the button, sleeve, next to the seams. Some models are equipped with a special iron, with which you can smooth out inaccessible folds. In this case, mechanical action is used together with the steam.

Previously, the steamer was used only in the atelier and in the garment factory. The devices were distinguished by their large size and high price tag.

Currently, manufacturers offer different models of steamers, which are divided into two categories:

- floor;

- manual.

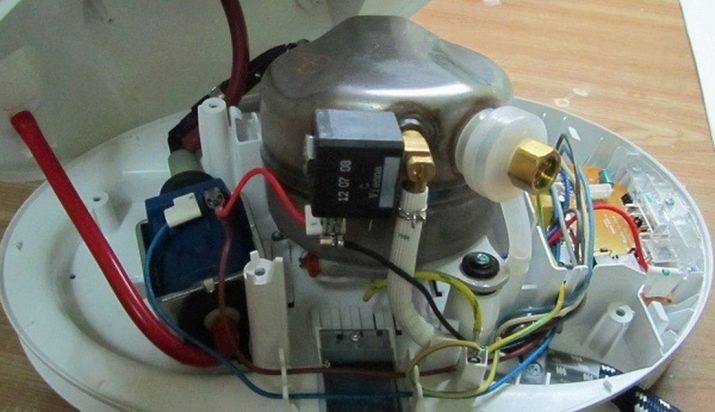

At home, you can usually find the second option. Its design is similar to a coffee machine. The steamer circuit contains the following details:

- boiler;

- water storage tank;

- electrical system;

- a piston equipped with a pump;

- spray.

The boiler is the main part. It contains a heater, thermostat with safety valve. The fluid from the tank moves through special tubes and, when heated, is converted to steam.Then the steam is sent to the atomizer, where the piston with the pump creates the necessary pressure level for atomization. All actions are carried out due to electricity, therefore, without fuses with wires, the operation of the steamer is impossible.

Types of malfunctions

Most malfunctions faced by the owners of the steamers can be resolved on their own. The most common problems are:

- the device is poorly steamed;

- steam leaves other parts of the device;

- the steamer does not produce steam;

- water heating stopped working.

Almost every defect can be eliminated independently and in a short time. For work, you should know what actions need to be performed and what subtleties of repair should be taken into account during repair. Naturally, you should know the device and the operation of the steamer, the functions of all its elements and parts.

How to repair the device?

Most owners of this equipment do the repair themselves. On your own, you can fix the stimulus if several conditions are met:

- the device was manufactured in China and does not have a guarantee on the territory of the Russian Federation;

- The warranty period has passed.

Before you begin to make repairs yourself, you should familiarize yourself with the technical documentation, and then proceed with the actions. It is necessary to disassemble the body part, ring the electrical parts. When working, it is important to make sure that there is resistance to electric current. After repair, you should connect the device for a short amount of time to the network to make sure that it is working. If the steamer is working properly, it can be assembled. This procedure is required in order to avoid multiple disassembly of the case.

If the cause of the malfunction lies in the thermostat tablet, the repair time may be extended indefinitely. Blown parts can be bought in a store or contact a specialized workshop for repair. These elements are produced with minimal chances to replace with analogues, so you need to look for the originals right away. Handicraft repairs in this case are completely excluded, since improper actions can lead to a short circuit, which can result in a fire. Before repair, the causes of each malfunction should be examined to reduce the time it takes to search for a damaged part.

No steam

Most often, this problem is associated with the formation of scale. Due to this, the heater does not allow heat to pass through well and clogging of the steam channels occurs. With such symptoms, a large-scale repair of the product is not required, simple cleaning will be sufficient. Such events can even be carried out by women. Two methods are effective for cleaning:

- mechanical;

- chemical.

For the mechanical method, disassembling the product will be required. It is carried out using a simple screwdriver. This will require:

- Disconnect the wires from the fluid supply system.

- Pull out the heater and descale.

- The water tank is washed with a solution of food vinegar. Alternatively, you can use a special descaling liquid.

The chemical method does not involve disassembling the steamer and disconnecting it from the network.

For cleaning you will need:

- water should be added to the tank with a solution of vinegar with a concentration of 3% (proportion 1: 1);

- then you need to heat the device to form steam;

- the procedure is carried out until the water evaporates.

Using this method, not only the heating element is cleaned, but also all the drain pipes and holes in the spray gun. In addition, the reason that the couple is not there may be hidden in the malfunction of the pump. Specialists recommend contacting this issue with specialized workshops, since troubleshooting will require disassembling the unit and turning it on when disassembled.

If it is not possible to take the stimulus to the master, you should study the rules for working with electrical devices. Due to the fact that the water pump is parallel to the heating element, the following steps will be required.

- Opening the case.

- Then you should connect the device to the network and check the voltage level on the pump. Its indicators should correspond to the data indicated in the model documentation.

- If the contacts are in working condition, you can pull the plug from the network.

- Then you should undock the terminals near the boiler. This is required in order to be able to ring not the heater, but the pump itself. Using a ping, you can determine the cause of the malfunction. If there is no signal, the reason lies in the motor.

The water tank is washed with a solution of food vinegar

This symptom most often indicates a pump malfunction. If this part is in order, you need to pay attention to the inlet valve, which is located at the inlet to the boiler. In its structure, the component is similar to a bicycle nipple, so repair work will be simple. To fix the malfunction, you need to unscrew the part and immerse it in a solution of citric acid. Some housewives purchase liquid for cleaning the dishwasher or washing machine. The inlet valve can be cleaned in any convenient way.

Steam comes out of other parts

If the steamer is often used, fistula may form on the hose. They may be invisible, but the vapor will still pass through them outward. If you do not pay attention to such a defect, the holes will become larger. It is best to use a hose replacement and not waste time on isolating a damaged part.

Water heating does not work

If the fluid does not heat up at all, the cause may be hidden in the boiler. It contains several parts that can deteriorate:

- thermostat;

- TEN;

- fuse.

To determine the cause, you should ring the heater using a tester. It is not recommended to carry out such a procedure at home, as it is accompanied by difficulties. You may need to replace the spiral, with which you can contact the service center. The fuse is attached to the body of the boiler with special brackets. These elements often fail and it is easy to replace them. To work, you need a tester, with which you should ring the fuse on both sides. Before operation, the plug must be pulled out of the mains. If there is no signal, this indicates a fuse.

The thermostat is a bimetal plate. This relay is responsible for turning off the current supply when the required temperature is reached. If the thermostat fails, it must be replaced. Repair in this case will be inappropriate.

Follow-up care

Steamer needs care. Timely service is a guarantee of long-term operation of the device. Service can be regular or service. Due to regular maintenance, the likelihood of repairs is halved. The procedure will require the following actions:

- after 50 hours of operation, the boiler needs to be flushed with running water;

- all tubes through which water passes should also be flushed;

- then you need to rinse the nozzles;

- the water storage tank is also cleaned of foreign matter;

- after washing, wipe all parts dry;

- elements should be wiped with a soft cloth that absorbs moisture well.

After-sales service should be carried out in a specialized workshop by professionals. During this procedure, the master will disassemble the unit, replace defective parts if necessary, and clean the structure. Such maintenance is useful, since the heater with fittings will be flushed in a special fluid that is not always available to a simple user. Industrial steamers are sent for service without fail, since they are often operated.The frequency of such maintenance of home steamers depends on the frequency of use of the device. If the stimulus was purchased for steaming several things a week, it is allowed to contact the workshop once every 3-5 years.

Water preparation

Some components that are present in the design of the stimulus may work worse due to aging. This behavior is considered normal in almost every unit. However, most of the problems are related to scale, so care should be taken about the steamer in order to avoid future repairs. To prevent the formation of scale, care should be taken to prepare the water. Many manufacturers indicate that normal operation will require distilled water, sold in car dealerships and pharmacies. However, such a purchase is quite expensive, so most users prepare the distilled liquid on their own.

To prepare, you will need a kettle, a heat-resistant tank and a water filter. The whole procedure takes a little time. The distillate is prepared as follows:

- water is poured into a kettle and brought to a boil;

- the liquid is poured into a heat-resistant container;

- after the water has settled, you should resort to filtering the sediment;

- For filtering it is recommended to use containers with carbon cartridges.

Using bottled water in a steamer

Often bottled water is found in stores, on which there is a note that it can be used in irons. Many people buy it, believing that the problem with the scum is solved. However, based on observations, it was noted that the use of such a liquid also contributes to the formation of scale. Differences in the use of plain water from the water supply system were not noticed. In addition, it should be noted that flavors may be present in bottled water that adversely affect clothing. Drinking bottled water in irons is not allowed, as it contains mineral components that have a detrimental effect on the device of the steamer.

See how to clean your garment steamer with your own hands in the next video.