For the preparation of products and dishes from them created a huge amount of a variety of techniques. But even the most sophisticated appliances are unable to replace ordinary kitchen knives. Therefore, this type of culinary accessories must be given close attention.

Features

By itself, the phrase “kitchen knives” comprehensively reveals their intended purpose - these are tools for cutting and separation of food products. But sometimes they are used:

- for peeling various fruits;

- to remove pulp from vegetables and fruits;

- to remove damaged and bad parts of various products;

- to give the workpieces a certain shape.

In most cases, universal knives are used for the kitchen. But professionals and advanced amateurs often prefer sets of specialized products. Knives are divided into a number of parts, each of which received its name. It is customary to highlight:

- point;

- blade;

- the neck;

- emphasis;

- shank;

- overlays;

- backdrop;

- rivets.

For the manufacture of kitchen knives, various materials can be used. Along with stainless, steel containing various amounts of carbon is used here. Titanium, ceramic, and even plastic constructions are also known. The blades themselves are made by forging or stamping.

The cutting edges are sharpened carefully.

Sizes and shapes

Over 30 varieties of kitchen cutting tools are known. In an ordinary house, of course, much fewer knife options are used. To cook 90% of the dishes at the disposal of the cook should only be:

- little;

- wide;

- large (long) knives.

Kinds

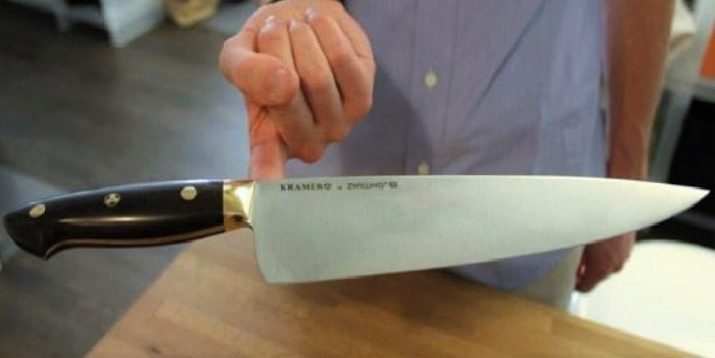

Impeccable classics of a kitchen knife are European products. This design has a perfect balance.The official name for this format is French Chef. For the manufacture of pens used wood. The handle is fixed on 3 rivets.

The European kitchen classic is equipped with a triangular blade with double-sided sharpening. From below, the blade protrudes markedly forward. The main structural material is stainless steel. The blade near the tip narrows significantly.

A similar design allows cooks not to tear off the cutting part from the board during operation.

The blade rests on the tip, and as necessary raise and lower in the hand. A simple chef's knife can be called almost universal: It performs well when slicing fruits, meat and vegetables. Important: this appliance is not designed for elegantly slicing bread. The blade in the chef's knife is close in shape to a triangle. The blade is 18-30 cm in length with a metal thickness of not more than 5 mm.

The main part of the structures is made no thicker than 2-3 mm. A variety of companies produce such products, so the choice is simply huge. The cost of a standard cook knife is relatively low. But it is quite heavy and not suitable for long work.

In addition to the fatigue of the cook, a small suitability for performing delicate manipulations may also be a problem.

In the current classification, a universal knife also appears. Its oblong blade extends forward, and the length of the blade reaches an average of 15 cm. Lightweight and relatively compact design makes this thing popular. Main scopes:

- peeling vegetables and fruits;

- shredder of the same plant products;

- cutting small food.

For the reduction in size and relief you have to pay the loss of the ability to chop and cut frozen meat. The next important type of kitchen knife is a device for peeling vegetables and hard fruits. The blade in length reaches no more than 7-8 m. For the manufacture of the handle, wood or polymers are used. Some options have a rounded profile to simplify peeling.

Another “vegetable” subtype has a pointed, somewhat understated tip. This solution helps a lot to take out the core of the fruit and get rid of the wormholes. The problem is that due to the modest size of the blade, it is not able to perform any other work. As for sirloin knives, they have a long and rather thin blade (10-34 cm). Products with a blade up to 15 cm are used when it is necessary to process fish, poultry or meat cutting.

Longer options help to cut the fillet. Sharpen the filet type at an angle of 15 degrees, and raise the tip of the tip. Such innovations to the limit facilitate the thinning of meat and fish raw materials. An important requirement when creating a fillet knife is the flexibility of its material. Too hard metal elements are simply not able to bend.

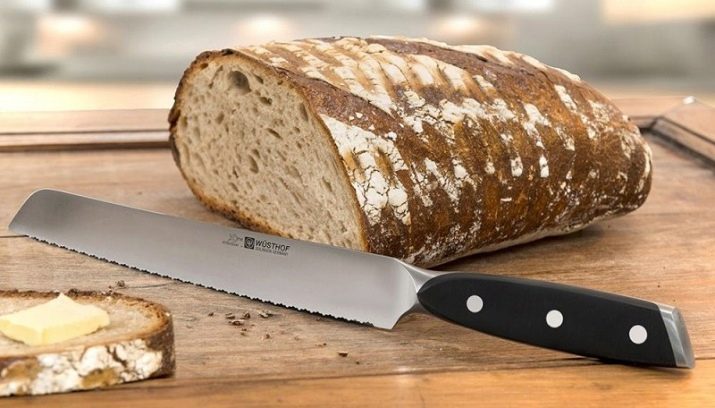

Bread knives are equipped with serrated blades. In length, it reaches 20-25 cm, and the width of the entire blade is exactly the same. At the end there is a characteristic fillet. The material must be extremely hard, because flexibility is not too fundamental. A characteristic feature of a bread knife is a serreytore sharpening, capable of cutting through a strong crust and not crumple crumb.

The same design helps cut large fruits and vegetables. In the practice of experienced cooks, boning knives are also a frequent help. Their main task is to conveniently separate the meat from the bones. The blade has an average length (not more than 16 cm) with a slightly curved profile.

The blade is characterized by medium hardness, and its most important parameters are elasticity and flexibility.

In addition to deboning, such a knife will help to chop and chop small products. To work in hard-to-reach areas, use shorter versions with a pointed triangular blade. Cutting knives are also gaining more and more popularity. They are needed not only for cutting meat carcasses, but also for chopping medium-sized bones, cartilage.Some culinary specialists use a cutting knife at the initial stage of deboning.

If not limited to European types of knives, then You can pay attention to Japanese products. Quite a few cooks use only such products. For their manufacture mainly steel with a high carbon content is used. To achieve the highest hardness, Rockwell hardening is used. The cutting properties of Japanese models are as great as possible, they can be recognized externally by the butt going down to the edge.

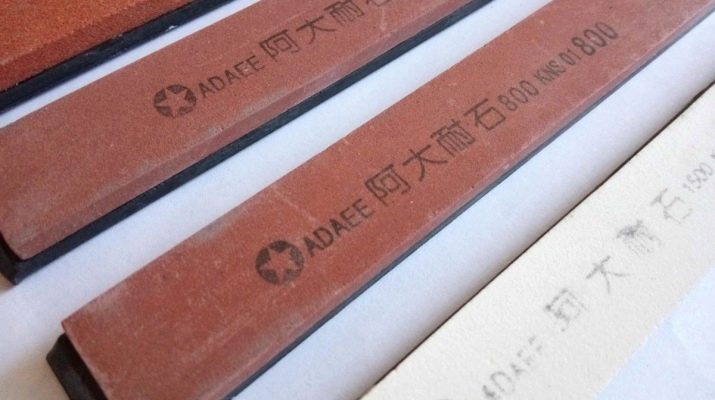

This solution allows you to align the work surface as much as possible. But a high carbon content reduces fluidity. But because the blade is extremely poorly sharpened. Special grinding whetstones come to the rescue. Most often, sharpening is done according to a one-way scheme.

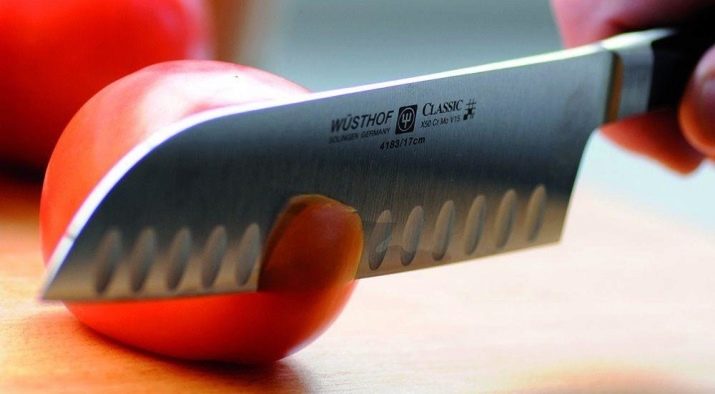

The term "santoku" in Asian industry means the same as the multifunctional cook knife in the European system. The high popularity of such a product has led to its inclusion in the product range of all major manufacturers. The blade is very long (16-20 cm), its width varies from 4 to 5 cm. Similar characteristics make it possible to use santoku instead of a scapula for cut products. Another Japanese knife, deba, is designed to cut and process fish, poultry and meat, however, it does not cope well with chopping large bones.

The classic deba is 16.5-20 cm long (along the blade).

The upgraded subspecies (i-deb) have blades 13.5-27 cm. In Japan itself, the deba is done with one-sided sharpening, but the models shipped to other countries are sharpened on both sides. As for products from damask steel, these are not just beautiful and reliable knives. Behind them are centuries-old traditions.

The production technology of real damask steel is extremely difficult and exclusive. In the past, it took several years to get a single blade. Recreating the recipe required many decades and took the strength of dozens of experienced metallurgists. But a folding kitchen knife, unlike damask, is nothing more than a curiosity. Such products may still be acceptable on a camping trip or on a business trip, but for serious home cooking, especially for haute cuisine, they are ineffective.

All-metal knives play an important role in camping life, hunting and fishing, in metalwork, carpentry, car repair and construction. The point is not that they are much sharper than usual, but simply in increased reliability. The metal handle breaks much less often than plastic or made of wood. This circumstance is especially valuable in extreme situations. A knife such as a saw, on which the review ends, is suitable mainly for cutting bread.

How to choose?

Just sorting out the basic options for knives is not enough. Making a good choice for your home is much more difficult, it’s even more difficult to choose the right tool for a professional kitchen. For a standard home set, if there is no experience, you need to select the following types:

- universal;

- chef;

- vegetable;

- bread;

- cleaver;

- sirloin knife;

- knives for cutting;

- whetstone (of the same manufacturer as other tools).

Important: you should immediately refuse to purchase an already packaged set of knives. If there is no way to check them in your hand, or even better - in fact, it is unlikely to make the right decision.

Each person should evaluate the tool in work purely from his point of view. What is good for one may not be suitable for the rest (and vice versa). Of course, you should not buy very cheap models, especially if they are also wearing a popular brand.

Of great importance is the strength of steel. Inconsistency of markings and price tags or accompanying documents should immediately alert. Note: it is necessary to check all the joints and junctions.Structures that are ideal in terms of strength are made of solid hand-forged steel. But they are not found too often and are extremely expensive.

It is difficult to say for sure whether light or heavy knives should be considered the best. The first cut faster and more accurately, less time consuming to work. The latter are much better at cutting solid, especially frozen, foods. The balance of the design should be optimal, the advantage of both the handle and the blade is unacceptable. Since ancient times, there is a way to check: put your finger on the joint of the blade with the handle and, supporting the knife horizontally, direct it with a sharp edge down.

A truly balanced product will remain in perfect balance and will not fall. But such a check must be carried out very carefully. With the slightest carelessness, it can be dangerous.

It is important to understand that only the most expensive models pass this test successfully. More than 90% of serial production is not designed for it.

The next step when choosing is to evaluate the handle. It must be firm enough, because considerable effort is applied to it. Easy to wash and thoroughly attach. Important: when there is even a small gap at the junction, it can serve as a drive for small particles of food. Subsequently, the sanitary characteristics of the knife will deteriorate.

In most cases, knives with a wooden and plastic handle are used in the kitchen. Products with bone handles can look attractive, but gradually the bone loses its strength. There were times when an old bone plate crumbled directly in the hand, causing injuries. Do not buy models with insufficiently dense and very soft wood. Strength is the primary property of a solid handle.

As for ceramic blades, then, according to many experts, this is perhaps the best option. The ceramic tip can be sharpened as well as a scalpel. Later it will not become less sharp and will not rust. However, the fragility and too high tendency to break greatly complicate the operation. In addition, decent quality ceramics are unnecessarily expensive.

Normally, the cutting surface of the blade extends along its entire length, from one end to the other. It is extremely important: gear modifications are not suitable for cutting meat and vegetables. The notches will constantly slide off rather than cut through the material. Sharpening is ineffective. It is definitely worth giving up products that are positioned as “incredibly universal” - all such designs are not too perfect and very unreliable.

You need to spend money not so much for the brand, but for real quality. Brand fame is not too important. It is unreasonable to buy a knife in the first available store. It is necessary to compare offers from different suppliers in order to identify the best option among them. It is better to focus on direct sales from manufacturers, rather than on resellers.

Choosing a knife as a gift for a professional chef, you need to evaluate not only the appearance, but also the ease of care, and the service life.

Soft alloys are easier to straighten and sharpen. But you have to carefully take care of the product. In addition, despite the hygiene of soft alloys, there is a serious drawback - a violation of the taste of the products. According to professionals, carbon steels are better than stainless alloys.

A compromise between the contradictory properties of soft and hard metal in a sense is the lamination technique. Carbon-rich brittle steel is surrounded by a softer alloy shell. Similar designs are realized by the large Japanese company Yaxell. As a base, metal with a strength of 60 to 64 units on the Rockwell scale is used. The outer damask shell prevents rust and increases the strength of the product.

When choosing between knives with a ceramic blade, it should be noted that the very first models of this kind began to produce the Japanese company Kyosera. Her vast experience deserves respect.The white type of ceramic is less durable than having a black color. Important: connoisseurs of European cuisine should not purchase classic Japanese knives. But the hybrids that are more convenient in configuration, preserving the lightness and strength of Asian modifications, are quite good.

When choosing a knife for hard cheese, you need to give preference to spatula-shaped versionsthat have a slot in the middle. Soft cheeses are best cut with tools that have a thin metal string instead of the usual blade. A universal type of cheese knife is useful for those who want to just cut heads for themselves without any frills. It will be very good if the end part is bifurcated - it is easy to prick chopped slices of products onto this kind of fork. There are also highly specialized modifications: scrapers for removing scales from fish, pizza knives (with a toothed rotating disk-shaped blade), some other modifications.

Manufacturers Overview

There are many companies offering luxury knives. However, highlighting the best among them will not work. Branded Japanese models are delivered mainly under the brands:

- Kukuichi;

- Hattori;

- Masahiro;

- Global

The most advanced European brands placed their production in Germany and France. Less demanding customers may prefer products from Swiss, English and Italian factories. Of the Chinese samples, the Rondell Flamberg RD-681 deserves attention. Knives are very good at cutting meat, and in addition are inexpensive.

The price is approximately 50% less than similar offers from competitors.

This knife is suitable for both ordinary people and professionals. The hardness and sharpening of the blade allows even strong products to be cut for a long time. The rubberized handle excludes sliding of the tool. Difficulties may be associated with the care of the RD-681. In addition, some experts say that rubber pens are unsafe for the environment.

For slicing tomatoes, it is recommended to use Fissler 8803013. This is a solid German model, the high quality of which is manifested in every detail. For delicate culinary work, this is perhaps the best version. The combination of a sharp edge and good polishing of the rest of the blade helps to make thin slices even from soft vegetables. The sharpness and strength of the blade are guaranteed for a long time.

An attractive alternative is BergHOFF Leo 3950045. This is an excellent Belgian product, also coping with soft vegetables. The blade was made of stamped steel with a coating to which cut pieces do not stick.

The polymer also retains corrosion for some time. True, the coating itself is not too durable.

Reviews

A lot of positive feedback goes to Apollo knives. The main thing is to choose not the cheapest, but slightly more expensive designs. Consumers appreciate ergonomics, balance, metal and stick quality, perfect cutting and long-term sharpening. Of the relatively cheap versions, Borner knives are highly regarded. They have a comfortable grip and a comfortable size.

The Asia family is distinguished for its specific configuration by handles and thin blades. Most of the models in this series have technological holes, which makes them very convenient for cutting soft products. With short-term refinement of musat razor sharpness is achieved.

Editing is done without any problems. But gentle treatment is required.

Positive marks give Alessi knives. These are small, well-cutting and comfortably placed products in the hand. Periodic sharpening is only required when used on glass boards. The whole metal handle is washed and cleaned without any problems.

Of Japanese knives, Keiko Santoku from Nadoba is very popular. The knife is made in a traditional national style. The plastic handle fits into your hand without any problems and does not slip. Each instance is sold in a separate plastic case.Labeling covers contains information about the material and the manufacturer.

Santoku is extraordinarily sharp. Through holes of the blade prevent sticking of chopped food to the blade. But this product is not suitable for those who appreciate heavy knives. The method of execution of the tool (inserting the blade into the handle without a guard) is not reliable enough. Over time, the joints may become loose.

In the expensive price group, along with Wusthof, there is at least one more brand - Zwilling J. A. Henckels. If we talk about products of moderate cost, then Victorinox, Arcos stand out. And in the budget category it is worth paying attention to the products of Tramontina, Opinel. If you are not limited to chef knives, you can take a closer look at Tupperware products. Other best brands for inexperienced cooks are Shun, F. Dick.

The last of the listed brands has only one drawback - increased cost.

Fans of domestic products should pay attention to products from Gennady Prokopenkov. They are made by the master himself with full diligence, with full knowledge of the matter. To purchase such a thing is quite difficult, and its cost is high. Goods made by Prokopenkov are easily controlled by musat.

See how to choose which kitchen knife in the video below.