Butchering is not always limited to the use of conventional kitchen or hunting knives. If we are talking about large pieces of beef, pork, lamb carcass weighing ten or more kilograms, or you need to cut chicken or large fish like catfish or carp, chopping knife for chopping is an ideal choice.

Appointment and execution

A knife-ax is the younger brother of an ordinary ax. Its structure is such that the blade has a shape remotely similar to a real ax. It protrudes forward in the form of a square rounded at the edges, which allows you to wield such a product without intense chopping movements with your hand. Unlike an ordinary ax, the butt is thickened, but not clumsy in shape. It is an indispensable tool for cutting both layers of meat in which small and medium-sized bones are found, as well as chopping frozen fillets.

This is an indispensable tool for meat packers in the kitchen of a hypermarket or a large cafe, whose menu contains an abundance of meat and fish dishes.

The hatchet knife is suitable for chopping meat and bones, cutting meat precisely “along the joints”. It has a wide and heavy blade, which makes it possible not to chop meat like a sausage, but to cut it in a structured and clear manner, preserving the fibers that hold their juices and liquids.

If you used the usual blade, which such work is not possible, the cut meat would resemble squeezed lemon in consistency. Cutting bones with a hatchet knife does not imply the formation of bone crochets during cutting movements, which discourages people from wanting to eat a dish made from meat, in which such fragments often come across.

The hatchet knife facilitates the work of the cutter or cook when cutting a large number of carcasses of livestock or poultry. This allows you to increase the productivity of people for whom cutting meat is the main responsibility in enterprises that manufacture finished meat or fish products.

Additional features

The center of mass of the hatchet knife is between the blade and the handle, and not somewhere inside it, or in the middle of the blade. This allows you to achieve maximum cutting (chopping) effect.

A good sign can be a special ring for hanging a knife on a hook - this is how you can place the entire arsenal of knives used for cooking in a narrow and limited space.

A knife-chopper is often a U-shaped point, but with “square” turning edges on one side, or a heavy and short blade, the length of which approaches its width. It can be strictly square in shape or in the form of a short rectangle, the front and lower cutting sides are adjacent, and a pointed angle allows you to pierce hard-cut ligaments, bones and cartilage.

Examples of hatchet knives

It is important to buy a quality knife-ax - experienced cutters and cooks recommend, for example, the following products.

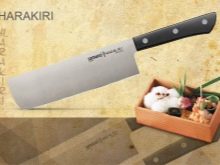

- Japanese Samura Golf Nakiri with a blade length of 167 mm. The total length of the knife is 305 mm. Product weight - 103 g. It is made of AUS-8 steel with a hardness index of 58 units on the Roxwell scale.

- Swiss Victorinox 5.4063.18 - made of rolled molybdenum-vanadium steel with a hardness of 56 units, blade length - 216 mm, knife weight - 310 g.

- Chinese Mr. Blade camp - AUS-8 steel with a hardness of 58 units, the length of the working part is 184 mm. Thanks to the powerful handle, such a knife weighs 663 g.

As customer experience shows, the best cutlery products (not necessarily cleaver) are made by Japan, Switzerland, England and Brazil.

How to choose an ax knife?

The basis for the correct choice of knives-hatchets are several important parameters.

- The blade should be wide and thickened.. The optimal balance between the weight and the force applied to cutting is the main criterion when choosing a knife with a blade that is most effective and easy to use. The length of the blade is most often 15-25 cm, but the width should be at least 8 cm, otherwise it is no longer a billhook, but an ordinary kitchen knife.

- Shortened handle with a rounded transverse shape, with hollows to hold the entire structure with your fingers. This allows you to achieve the most reliable coverage, significantly reducing hand fatigue during work.

- Double-sided sharpening. One-sided will lead the edge to the side, which is why cutting products will require significantly more effort. Sharpening a blunt blade on both sides is simpler - you still sharpen a knife not one-sided, but in two ways. The sharpening angle must not go beyond 15-45 degrees: the larger one makes it difficult to cut the meat, the smaller one makes the knife unusually thin, like a razor blade.

- Steel quality - Must be stainless, not carbon. The latter is covered with a brown coating, when the knife is not immediately washed, it becomes thinner quickly, it is increasingly difficult to make it sharp again when dull from frequently encountered bones, and the food tastes like iron. Rusting products are cheap, but do not save on price. Damascus steel or titanium is strong enough, the first requires special care, the second, on the contrary, is unpretentious in use and significantly lighter.

- The best choice would be a metal handle, not a wooden or plastic one. The metal does not burn and does not melt from high temperatures, for example, when a knife is accidentally thrown dangerously close to fire. Completely steel product is easy to wash, it does not hold odors. A solid cast knife does not need rivets and bolts. Disadvantages - decent weight (more than a kilogram) and high price.

- Finally, before buying a knife-hatchet, check it for workmanship: no wear (numerous scuffs and scratches, indicating that the tool was used somewhere for a very long time and was repeatedly grinded), chips, potholes and notches.The latter report that the knife was generally used for other purposes, for example, by striking a hammer on its butt with a hammer, pieces of wood were chopped onto chips.

Overview chopping hatchet Mr. Blade Camp awaits you next.