Human life is impossible without food, and now quite a lot of kitchen utensils are used for its preparation. One of the most sought-after items, without which it is difficult to imagine cooking, is a knife. High-quality knives help to quickly grind the necessary products, clean them and cut the meat or fish. It is far from always possible to get a product from good materials, and soon the knives begin to blunt, making it very difficult to work with them.

To save the situation, you can sharpen it with a bar, but the result will depend on the correctness of this action.

Why is the knife dull?

In the market and in stores now you can find a lot of knives that differ in their appearance, size and even material, but one thing they have in common is that sooner or later they all get dull.

This process can be faster or take months or even years, depending on the quality of the material from which it is made and the load that is placed on it.

The most common cause of deterioration in cutting ability is steel damage from daily use. The working part is constantly subjected to a load, therefore, microparticles begin to break off from it, which affect the quality of cutting.

The second reason the knife is blunt is a violation of the correct cutting angle. Few people know how to hold knives at all during this process, but because the inventory very quickly and greatly wears out, solely due to the fault of the owner.If during cutting there is a need to exert more and more efforts, then this is a clear sign that you need to sharpen the knife.

A number of verification activities can be carried out to confirm or refute the need for work to improve the sharpness of the device.

- To check you need a hemp rope, which folds 4 times. The challenge is to cut it with a knife at a time. If you can do this without problems, then the knife is still quite sharp - there is no need to sharpen it. If the rope remains intact in some places, then the time has come for the procedure.

- The second method involves the use of a file that needs to be drawn along the blade of a knife. If it slides, then the knife is still suitable for full use. If notches and chips are felt, then sharpening is indispensable.

- For the simplest verification option, you will need a simple sheet of paper that needs to be cut by weight, holding it by the edge. If the knife goes smoothly and easily cuts the sheet, then it does not need correction, if the blade moves intermittently, if not at all, then the product urgently needs to be sharpened.

As soon as the condition of the knife is established, you can either use it for some more time or grind it using the appropriate equipment.

Types and selection of whetstones

To choose the right whetstone for sharpening knives, you need to know what types and options of these products are. Today we can distinguish:

- whetstone or musat;

- electro or mechanical sharpener;

- grinding tool for grinding.

Most often, it is the bars that are used at home, the main difference is the granularity or abrasiveness of the stone, which can be:

- fine-grained - used for high-quality grinding of the tip surface;

- medium-grained - it is necessary to give the desired and correct shape to the knife blade;

- coarse-grained - needed to give the correct shape to the tip and restore the desired angle on the knife.

If we take into account the material from which such bars are made, then we can distinguish such varieties:

- natural materials: flint, corundum, diamond, emery, garnet;

- artificial materials: borazon, elbor, silicon carbide, synthetic samples of diamond, electrocorundum.

Such varieties can be thin, small and coarse. Different manufacturers make sharpening stones of various sizes, which is convenient for large, medium or small knives.

The most convenient is considered an elongated diamond stone, with which you can eliminate any problems with the sharpness of the knife as soon as possible. A bar can be round, but it is not very convenient to hold it in your hand, because such products are most often produced for electric sharpeners, which are recommended for use exclusively by professionals, otherwise you can spoil even the highest quality knife very quickly.

If we talk about the design, then it can be:

- abrasive outer layer, which should be stronger and harder than the material to be sharpened;

- a matrix with softened material (clay, ceramics, technical faience) that allows you to hold small particles, and this layer should be softer than abrasive, but harder than the material to be sharpened - this design is necessary for uniform erasure of the bar and the formation of a new and new layer of crystals for sharpening.

If we consider all varieties of whetstones for sharpening knives, then it is worth highlighting the most common.

- Diamond bar. Most often used in domestic conditions for sharpening kitchen knives. It is easy to use and store. Diamond particles are very durable and do not wear off for a long time. The product itself is very strong and does not crack even when dropped from a height. Of the relative shortcomings, only roughness and abrasion on the knife blade can be noted, which leave quite large crystals on the bar.

- Elborovy. This bar is made using a chemical reaction of a boron compound. In terms of basic characteristics, it is not inferior to a diamond bar in any way, but it is also resistant to chemical influences. The advantage of this product is the lower granularity of the working surface, as a result of which it does not deform the blade of the knife, allowing it to be sharpened filigree.

- Ceramic. Created during the baking of ceramic bars. The advantages are low cost and good durability. Of the minuses, it is worth noting: clogging with metal residues from the knife blade in a short time, as well as the difficulty in cleaning grains.

- Japanese water stone. It is created using a silicate matrix and carbide grains. In order to sharpen the knife qualitatively, the bar is soaked in water for 20 minutes, which will allow polishing and sharpening the knife blade with the highest quality, although the work itself will be quite dirty. It is very difficult to care for such a device, but this is its only minus.

- Whetstones made of natural stone. The base of the product is quartz, and the matrix can be any sedimentary rock. In order for the work to be done well, it is best to have several options that vary in rigidity. For proper operation, the product is lubricated with mineral oil.

- Fine sandpaper. It is a dense sheet with abrasive material that does not last long, but in an emergency can help sharpen the knife.

To get a high-quality result, the paper must be moistened with soapy water before starting work.

To choose the right bar, you need to know the main characteristics of each of the options, as well as their purpose.

How to prepare the tool for sharpening?

To sharpen kitchen knives, you must have a clear understanding of this procedure. Each knife is unique, as it can be made of steel of various densities and qualities, and therefore sharpening bars are selected in accordance with these properties. Preparing the knife for the procedure looks like this:

- determine the hardness of the blade, which will make it possible to choose the bar of the desired grain size;

- wash and degrease an existing tool;

- the dry prepared kitchen knife is completely ready for work.

Sharpening knives with any bar can have various consequences: either the product can be made sharp, or it will be completely damaged. Knives with a soft blade need fine-grained sharpeners, and with hard ones - coarse-grained. Wrong choices will nullify all efforts.

Preparing a knife is an important step, as a dirty or greasy tool will be harder to process or will not work at all. When washing the knife, it is necessary to degrease not only the blade, but also the handle, so that the utensils do not fidget in the hand during operation or accidentally slip, which can cause serious injury to the person who is sharpening the knife.

If the blade is left unprepared, it may become deformed or scratched, which is a negative result of work.

Before you start sharpening knives, it is worth checking their sharpness, for which it is enough to assess the smoothness of the tip. If it is embossed and uneven, then the situation should be corrected immediately. In the case of a smooth and even surface of the knife tip, there is no essential need for additional sharpening of the surface. Once the necessary kitchen tools are identified, you can take on the work, which must be performed in strict sequence and according to certain rules.

Step-by-step instruction

In order to sharpen knives manually, you must know the specific rules of this event. At home, you do not always have all the necessary equipment, but from the available parts you can always build a suitable working area. The most important rule is the fixation of the bar, which allows sharpening efficiently with two hands, without fear of unexpected injuries or injuries.

To sharpen knives correctly, it is necessary to lay the bar on a rubber mat or fix it in other ways, at the same time, lifting it above the working surface in order to exclude adverse contact with the table or worktop where the work will be performed.

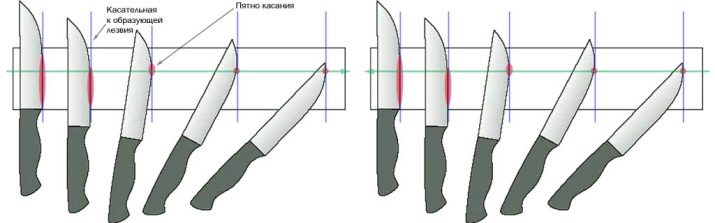

Once the bar is fixed, you need to do the determination of the angle of sharpening of the cutting surface. For each product, these values will differ: for a scalpel, you need to set an angle from 7 to 18 degrees, for a kitchen knife it increases to 25 degrees, production knives that cut more durable products are sharpened at an angle of 25–35 degrees.

The technology of sharpening a knife at home with a stone looks like this:

- the knife is pointed with a point perpendicular to the bar, after which it bends at the right angle so that the edge is in front;

- to sharpen the tip, you need to lead the knife forward in a smooth, but confident movement, trying not to change the angle of the product;

- the tip of the knife should be final, after which the movement is repeated again;

- it is important to ensure that the cutting part does not come off the bar, as this can cause its deformation and the formation of chips on it;

- the sharpening technique is the same for both sides of the knife: as soon as one has been worked out, it is necessary to change the side and repeat the manipulation again;

- work continues until the cutting surface is completely smooth and thin.

To sharpen a knife, it is enough to walk them on a coarse-grained bar, but such a product is not suitable for use, since it quickly becomes dull again. It is very important to grind the surface, which can be done using fine-grained timber. Processing in this case occurs in exactly the same way as when sharpening knives.

To work confidently and fairly quickly, it is very important to moisten the blade with water or apply special oil before starting. As soon as the characteristic burrs appear on the tip, the product is ready for the next step. To polish a knife with high quality, it should also be lubricated before work.

The final stage of the work will be checking the sharpness of the blade, for which the most reliable will be cutting a regular sheet. With perfect sharpening, the cut is smooth and fast. If the manipulation was carried out with violations, then this will immediately affect the result. Do not check the tip with your fingers, as there is a big risk of injuring the upper layer of the skin and causing an infection.

All these rules will help to quickly and accurately sharpen a knife, even without prior preparation.

Useful Tips

To sharpen home knives yourself, you must be able to properly carry out this manipulation. In addition to obtaining theoretical knowledge, it is worth testing them on old products, which will not be a pity if something goes wrong. As soon as progress in work is obvious, you can safely proceed to sharpen all the knives that are in the house and need to improve the quality of cutting.

It is worth remembering that cutting products with different purposes have a different angle of inclination, which is very important to withstand during sharpening:

- Japanese-made knives must be kept at an angle of 10–20 degrees;

- professional equipment and fillet knives are usually kept at an angle of 25 degrees;

- for ordinary household knives, the optimal angle would be 30 degrees;

- for hunting knives, the angle should be increased to 35–40 degrees.

In the process, it is important to push the knife slightly so as not to break the abrasive particles from the bar. Sharpening knives is not an easy task, since you need to set the angle of inclination correctly, pick up the right bar, apply moderate pressure and make sure that the blade does not come off the sharpening.

If you use the bar too actively, then it will soon appear bumps and dents that will interfere with the use of equipment. In order not to have to buy a new product, you need to grind off the extra layer, aligning the bar over the entire surface, and again use it for its intended purpose.

It is best to carry out the adjustment process using an electric machine that will evenly remove the abrasive layer.

It’s important to work in a respirator or gauze dressing, since there will be many microparticles in the air that should not enter the human respiratory system. Maintenance in the order of inventory and timely maintenance of tools will allow them to be useful and necessary for a long time.

See how to sharpen a knife on a stone in the next video.