Japanese kitchen knives Samura - products that harmoniously combine ancient grace and sophisticated aesthetics, convenience and functionality, practicality and durability. This is exactly the case when the ergonomics of the form smoothly transforms into the perfection of the blade.

Brand Information

Japanese Samura knives are not just a brand, but a product line designed specifically for Russia. The fulcrum in the creation of the company and the formation of the brand in this case were the ancient knife traditions of Japan. Having retained the main parameters of the products of the country of manufacture, accuracy and their high quality, the production managed to adapt the shapes of the blades and handles to the habits of the Russian consumer.

Today Samura is the result of modern production, which uses the best grades of Japanese and Swedish steel.hardened to a hardness of 58 - 61 HRC. Blades of a traditional Japanese form, with a subtle reduction from the butt, provide the famous fantastic cutting performance (fantastic cutting effect).

A well-thought-out product line of produced categories and series of models allows you to pick up convenient work sets for both professional chefs and housewives.

Knife Features

A special respect for knives in Japan has developed historically, during the time of the samurai. Knife forging technologies from ancient masters, as well as rules for sharpening and caring for cutting tools, have come down to our time and are widely used. The Japanese desire for excellence, aesthetics and beauty was directly embodied in the art of manufacturing cutting tools.Modern kitchen knives have largely preserved the shape and quality of blades, and the use of advanced technologies in their manufacture gives products improved quality characteristics.

A major shift in the manufacture of kitchen tools was outlined in Japan after the Second World War, following the ban on the production of knives. The masters did not have to fundamentally rebuild, but merely put in a different way some emphasis regarding certain sizes and geometric parameters in the manufacture of kitchen knives. Today, good knives are made for professional cooks and housewives in Japan, including from Damascus steel, among which are new models, and traditional, and cutting products adapted to Europeans

In its classic version, Japanese products differ from traditional European models. Characteristic features are: a massive knife butt, a blade more elongated in shape, as well as the use of a one-sided type of sharpening. Moreover, sharpening is made to order both for lefties and righties. The narrow blade of Japanese knives allows for finer kitchen operations. The use of such knives requires some skill.

The main difference between Japanese knives is the quality of steel and other materials used for their manufacture, as well as the design features of the blade. In production, expensive high-carbon steel grades are usually used. Therefore, the blades have a high level of hardness, higher than that of analogues from Europe.

For this reason, Japanese models for a long time maintain the quality of the first sharpening and, as a result, the quality of the sliced products.

Varieties

Traditionally, preferring the quality of workmanship without compromising other requirements, The company sells products in several categories of Samura, which we note in a brief overview.

- Samura Pro-S - sets of high-quality products made of molybdenum-vanadium steel, popular among cooks. Prices are high.

- Mo-V High Carbon - models of universal application, ergonomic. Budget prices.

- Bamboo - with a unique handle shape resembling a bamboo stalk. In the manufacture of special grinding is used, not allowing the handle to slide in the hand.

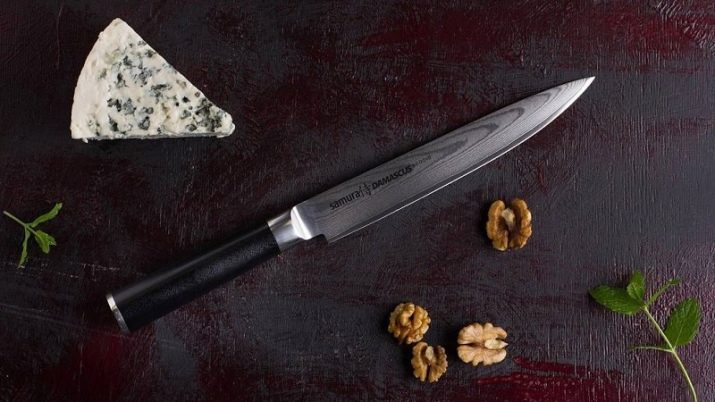

- Damascus - sets of models with a thin blade of steel, equipped with damask overlays for the delivered and continuous cutting.

- Tamahagan - Katana sword crafted technology. They have 33 layers of steel, reinforced with the composition of vanadium and nickel.

- Harakiri - equipped with unconventional acetal resin handles, with a perfectly balanced blade.

- Mac Black Fuso - reliable Teflon-coated cutting tools.

- Mac Original - products with excellent ergonomics and unique design.

- Mo-V High Cargon / G 10 - modern products with high anti-corrosion qualities. The handle is made of fiberglass;

- Segun - original models with laminated blades and fiberglass handles.

- Ceramotitan - products are made from the original composite with ceramic blades and a durable titanium coating.

- Eco-ceramic - comfortable and practical ceramic models.

- Fucion - products with ceramic blades and a plastic handle. Stylish, ergonomic and reliable.

In the categories you can highlight the most popular series.

- HARAKIRI - A series of affordable knives, made mainly of single-layer steel. Harakiri knives are especially popular with beginner chefs because they make it possible to complete a good working set of knives at a relatively low cost.

- DAMASCUS. The professionalism of Samura craftsmen is perfectly reflected in a series of damask knives - high-quality, reliable, durable and very convenient products. The steel used is prepared according to the original recipe, according to the latest technologies.

- ECO-CERAMIC - A series of classic ceramic knives of low cost, made in a minimalist, restrained Japanese style.

- CERAMOTITAN - keramotitan products that are not afraid of shock. Widely used by professional chefs in institutions with a large number of clients and a significant amount of work.

Each of these series includes knives for a wide range of purposes (fillet, nakiri, santoku, chef-knives, etc.).

With the advent of the latest technology, the company has mastered the production of knives made of zirconium dioxide. These lightweight products have enviable strength, toughness and durability. They retain their high cutting ability for a long time, are not susceptible to corrosion and aggressive environments, and are extremely convenient to use. Ceramic models are produced by sintering in special smelting furnaces.

For zirconium and other ceramic cutting products, there are certain operating rules: do not use them for cutting bones, or other especially hard products. They are not intended for either chopping or scraping. It is impractical to take them with you on hunting or fishing - ceramics are effective exclusively in the kitchen.

Samura knives made of Damascus steel are durable, flexible and equipped with a perfectly sharpened blade. Here, high quality is ensured by combining and creating multilayer products from various grades of high-carbon and alloy steels (for example, a series of five-layer Super 5 knives). These products are characterized by a characteristic layered structure of the blade, which provides both strength and beauty of the product. The manufacturing process is time consuming and involves a number of stages, which affects their relatively high cost. However, a long service life justifies the purchase of these knives.

Selection recommendations

When choosing a kitchen knife, it is necessary to consider, first of all, the material from which the tool is made. The optimal choice depends on the financial capabilities (cost of the product) and the quality of the product, its strength characteristics and durability. Perhaps the most elite chef's knives are Damascus knives, the manufacture of which uses sophisticated technology. Such knives can serve for decades and will not become worthless.

Steel knives are executed in single-layer or multi-layer versions. The carbon content of the knife steel matters. Japanese steel knives are effective, durable, easy to care for and quite affordable. Ceramic knives are inexpensive, effective, but require special care. Shocks to the product should be avoided since chips are possible. Accuracy in handling such a knife will be completely superfluous.

Keramotitan is considered an improved version of ceramics - it is more shock resistant.

In order to choose the right knife, it is important to clearly understand for what purpose it is needed. Among the knives "Samura" there are different types, distinguished by the scope of their application.

- Universal knives. In the classic Japanese version, they are called Santoku and can have a wide or narrow, medium-length blade. The steel for the knife blade and the material for the handle are selected depending on the specific situation and the cost of the blade. Blade sharpening is a direct method and can be double-sided for ease of use. In addition, such sharpening of universal knives provides excellent sharpness of the blade, which remains for a long time. Often you won’t have to sharpen the blade.

- Knives for fish and meat - an extensive category, including loin knives, for cutting steaks and separating meat from bones, etc. Combines these knives in one category their purpose. The length of the blade in the category depends on the specialization of the knife. However, more often the blade will be straight, with possible bends along the internal lines of the contour (the top edge remains flat). Steel is usually used multilayer, the blade is hard, but not always. For example, boning kitchen knives are quite flexible.

- Other varieties of knives, including auxiliary functionality, represented by knives: for bread, tomatoes, fruits, cheese, etc. In each case, they have their own specific features.

How to distinguish a fake?

Fakes in our modern life, unfortunately, are not uncommon. It is especially important to be careful if you purchase branded and expensive goods. In some cases, it makes sense to find a photo of the product on the brand’s website and carefully compare it with a store copy. Carefully inspecting the goods, it is important to consider that fakes usually give themselves away in designer details and their appearance.

When buying a product, you should carefully examine the logo, its location, color spectrum and other parameters. It will not be superfluous to get acquainted on the Internet with the opinion of experienced people who have fallen into such situations. Take a closer look at the letters - fakes of Chinese origin often contain a large number of grammatical errors and typos. The presence of smeared lines is a sign of fake.

Before buying a product, you should carefully read its description on the site. Any inconsistencies in the description and appearance of the real product should be suspicious. Knives are available with individual serial numbers, which are easily checked for their compliance with company standards. It will not be superfluous to study the accompanying papers for compliance with the article number on the package.

Minidefects in the appearance of the goods are also quite informative: inharmonious parts, small chips and roughnesses of the blade surface, sharpening defects, poor-quality cover, sloppy packaging with defective printing. Products should delight customers with their design.

It is advisable to purchase products in the corresponding company stores, which gives a one-year guarantee and often provides subsequent support.

Storage and care

Traditionally, the blades of Japanese Samura products are perfectly balanced and have a special sharpening angle. For this, exclusively special tools are used - grinding water stones. Sharpening knives should be in three stages.

- Editing the edge is done with stones with a grain size of 300-400. The stone is moistened and then sharpened with double-sided leading the blade along the surface of the stone at an angle of 25 °, until small burrs occur. Next, with a leisurely movement on one side of the blade, align the blade sharpening, and remove burrs from the back.

- For the main sharpening we use a stone with a grain size of 1000-1500. The sharpening process repeats the content of the operations of the first stage.

- For final finishing, stones with grit above 3000 are used, carrying out finishing with neat and smooth movements on one side.

For sharpening ceramic products, special tools with diamond spraying are required.

To ensure the preservation of the sharpening angle and preserve the geometric parameters of the blade, it is better to resort to the help of masters.

Any good thing requires proper and systematic care.

- Classic knives, even those made of good steel, must be wiped after handling wet products. Otherwise, a plaque forms on them. In addition, water contains chlorine, which reduces the level of corrosion protection, which leads to the destruction of the surface of the blade.

- Knives should always be washed immediately after use, without leaving the product contaminated for a long time. The washing procedure is best done manually.

- Proper sharpening is a guarantee of long-term operation of the knife. You can perform it as yourself, so give it to sharpening professionals. The final decision depends on the characteristics of the product - it is better to trust expensive knives to professional craftsmen.

- Damascus knife care is similar in many ways. Store the product in a dry place and prevent acid or alkaline substances from entering it.

- Kitchen knives, like their sets, should be stored in special coasters more correctly - this is practical and convenient. Damascus knives should not be stored in cases for a long time.

- The best option for cutting boards are wood or plastic products. Boards made of glass, like cutting on a plate, blunt the blade.

- Cutting frozen foods or chopping bones is not for knives. It is better and more convenient to use hatchets or special knives for this.

In the next video you will find the Samura 67 SD67.0023 knife test.